Manufacturing method of low melting point polyester

A low-melting-point polyester and manufacturing method technology, applied in the field of manufacturing low-melting-point polyester, can solve problems such as serious side reactions in the esterification process, high tetrahydrofuran, and affecting product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

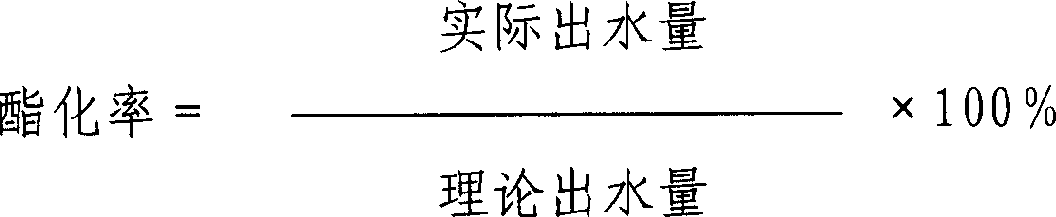

Method used

Image

Examples

Embodiment 1~8

[0027] A rectification column condenser and collector, a nitrogen pressurization system, a vacuum system, a heating device and a stirring device are arranged on a 2-liter stainless steel reactor.

[0028] Weigh ethylene glycol (EG) and 1,4-butanediol (BD) according to the required molar ratio, weigh the required amount of catalyst tetrabutyl titanate and dissolve them, add the materials to the reaction kettle, and start stirring , the material is heated to the desired temperature. Then weigh terephthalic acid (PTA) and isophthalic acid (IPA) according to the required molar ratio and add them to the reactor. Fill the reaction kettle with nitrogen, replace the air in the kettle twice, open the rectification column valve, control the required reaction temperature and reaction pressure, and first carry out the first stage of esterification reaction.

[0029] After the esterification reaction of the first stage is finished, the rectifying column valve is closed, nitrogen is filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com