Aluminum magnesium oxynitride/boron nitride diphase refractory materials and preparing process thereof

A technology of aluminum magnesium oxynitride and refractory materials, which is applied in the field of structural ceramics and refractory materials, and can solve problems such as low thermal shock resistance and difficult control of MgAlON synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

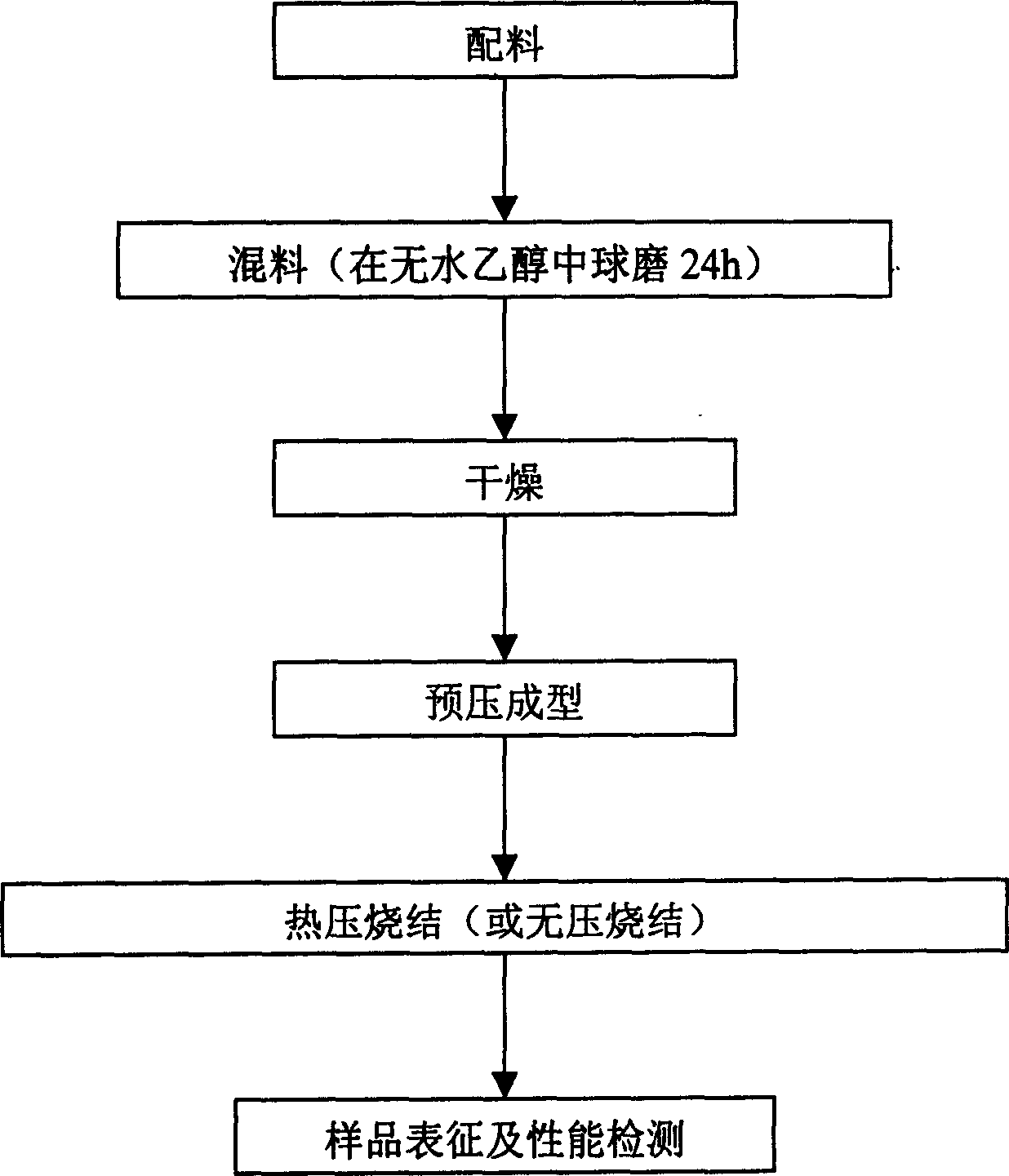

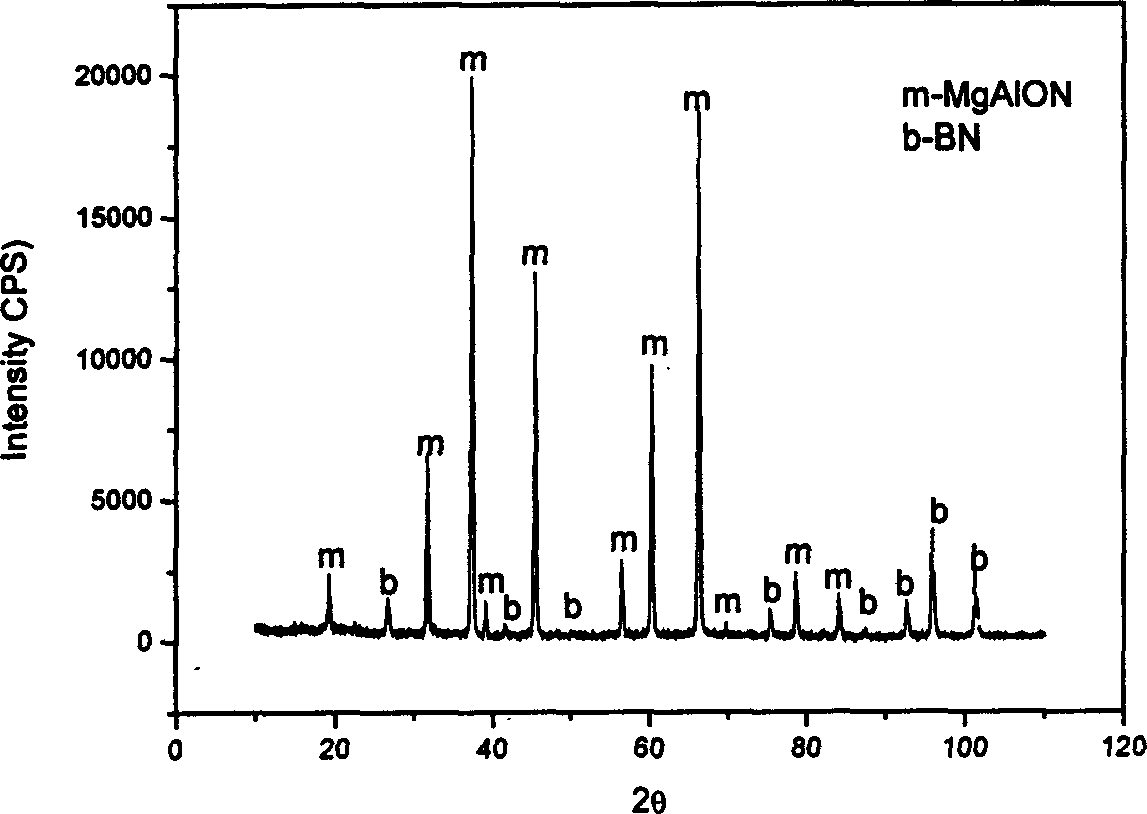

[0021] according to figure 1 Definite process route, the present invention has carried out the synthetic test of series MgAlON / BN composite material, to analyze pure Al 2 o 3 , AlN, MgO and BN were used as raw materials, and hot-pressed and normal-pressure synthesis tests were carried out. The raw material composition of the synthetic test is shown in Table 1. Natural raw materials were used as raw materials, and the normal-pressure synthesis test was carried out. The raw material components are shown in Table 2. In Table 1-2, Al 2 o 3 , AlN, MgO or bauxite, aluminum powder, and magnesia are the raw materials for the synthesis of MgAlON. According to the calculation of the theoretical density of MgAlON and the theoretical density of BN, it can be known that the volume content of BN in Table 1 and Table 2 varies from about 10% to 90%.

[0022] no

al 2 o 3 (mass%)

AlN(mass%)

MgO(mass%)

BN(mass%)

1

79.74

9.16

4.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com