Multifunctional corrosion inhibitor and preparing method

A corrosion inhibitor, multi-functional technology, applied in the field of multi-functional corrosion inhibitor, can solve the problems of lack of protection, foaming oil quality, increase loss, etc., to achieve excellent corrosion inhibition performance, low water solubility, dehydration fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

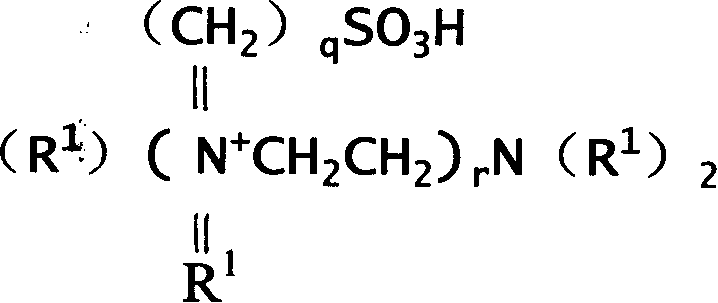

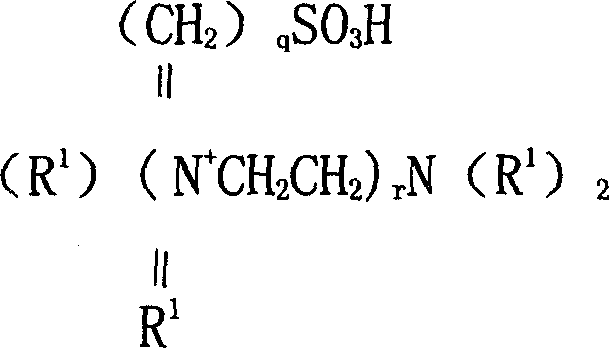

Method used

Image

Examples

Embodiment 1

[0010] 1. Propylene oxide (PO), ethylene oxide (EO) block copolyether

[0011] In a 500ml autoclave equipped with an electric stirrer, add 23.0g of diethylenetriamine, and 80ml of mixed xylene, and add 0.2g of potassium hydroxide as a catalyst. Under heating and stirring, 70.0g of PO and 15.0g of EO are sequentially introduced to react The temperature range is 120-140°C. After the absorption is complete, the xylene is distilled off under reduced pressure to obtain the desired polyether.

[0012] 2. Corrosion inhibitor synthesis

[0013] Add 41.0 g of polyether and 220 ml of absolute ethanol to a 500 ml three-neck flask with stirring, thermometer, and condenser. Carefully add 36.0g of sodium bromoethylsulfonate in three batches, the reaction temperature is 60°C, after the addition, reflux for 2.5 hours to remove the white solid in the solution by hot filtration, and then distill off the ethanol in the filtrate to obtain the finished product.

[0014] Corrosion inhibitor simu...

Embodiment 2

[0018] 1. Propylene oxide (PO), ethylene oxide (EO) block copolyether

[0019] In a 500ml autoclave equipped with an electric stirrer, add 23.0g triethylenetetramine, and 80ml mixed xylene, add 0.2g sodium hydroxide as a catalyst, and under heating and stirring, 70.0gPO and 15.0gEO are sequentially introduced to react The temperature range is 120-140°C. After the absorption is complete, the xylene is distilled off under reduced pressure to obtain the desired polyether.

[0020] 2. Corrosion inhibitor synthesis

[0021] Add 40.0g of polyether and 200ml of 1,2-dichloroethane to a 500ml three-neck flask with stirring, thermometer, and condenser, heat to 50°C, and slowly add 21.0g of 1,3-propylene sulfinic acid lactone dropwise (Dropping time is about 50 minutes), this reaction is an exothermic reaction, and external cooling measures should be taken, and the reaction temperature is 40°C. After the dropwise addition, the reactant was refluxed for about 2.5 hours to complete the ...

Embodiment 3

[0026] In a 500ml autoclave equipped with an electric stirrer, add 23.0g of ethylenediamine and 80ml of mixed xylene, add 0.2g of sodium hydroxide as a catalyst, and under the condition of heating and stirring, successively feed 70.0gPO and 15.0gEO, the reaction temperature Range 120-140°C. After the absorption is complete, the xylene is distilled off under reduced pressure to obtain the desired polyether.

[0027] Corrosion inhibitor synthesis

[0028] Add 40.0g of polyether and 200ml of 1,2-dichloroethane to a 500ml three-neck flask with stirring, thermometer, and condenser, heat to 50°C, and slowly add 21.0g of 1,3-propylene sulfinic acid lactone dropwise (Dropping time is about 50 minutes), this reaction is an exothermic reaction, and external cooling measures should be taken. After the dropwise addition, the reactant was refluxed for about 2.5 hours to complete the reaction. Remove the solvent under reduced pressure and cool the unreacted matter to room temperature, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com