Unequal pitch high speed transmission gear chain and chain wheel

A technology of high-speed transmission and toothed chain, which is applied in the direction of transmission chain, transmission device, belt/chain/gear, etc., can solve the problems of high cost, complicated process, difficult to popularize and apply, etc., achieve low cost, improve transmission capacity, eliminate Effect of Changes in Mesh Line Position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

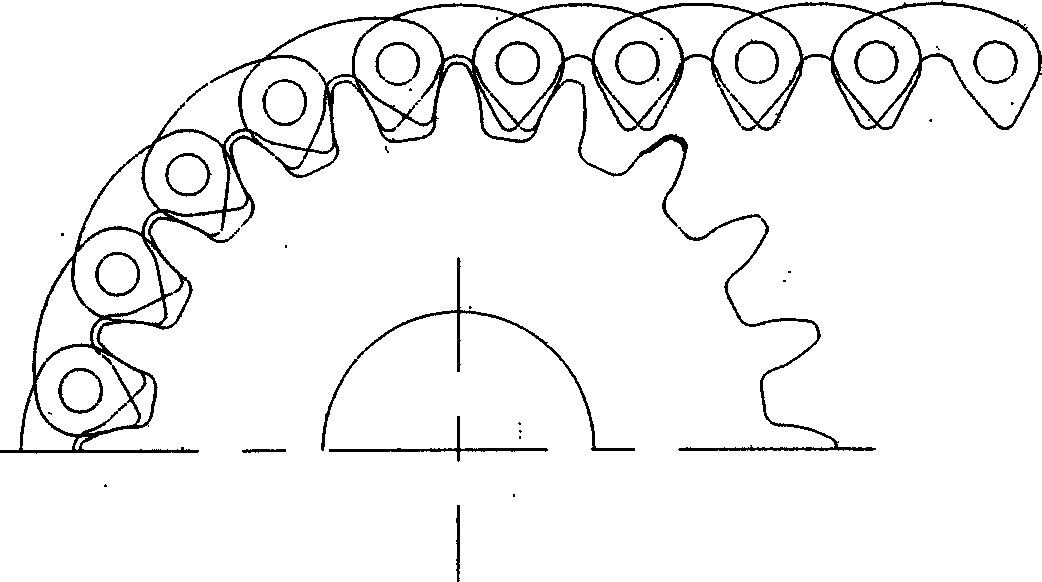

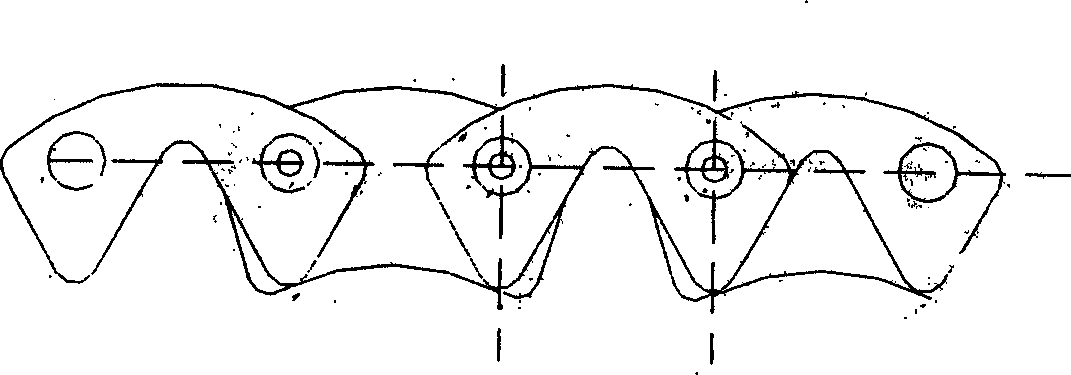

[0024] Embodiment 1: A small-pitch sprocket used for air distribution transmission between a motorcycle crankshaft and a camshaft. Figure 5 sprockets shown with image 3 , 4 The toothed chain of the structure shown in the diagram realizes meshing, the pitch of the chain is 6.35 mm, and the pitch of the sprocket is 6.34 mm. The toothed chain and the sprocket are meshed by point contact, the impact speed of meshing is small, the noise is low, and the service life is long. It is suitable for high-speed transmission with a linear speed of ≥25m / s and a rotational speed of 6000~10000 rpm.

Embodiment 2

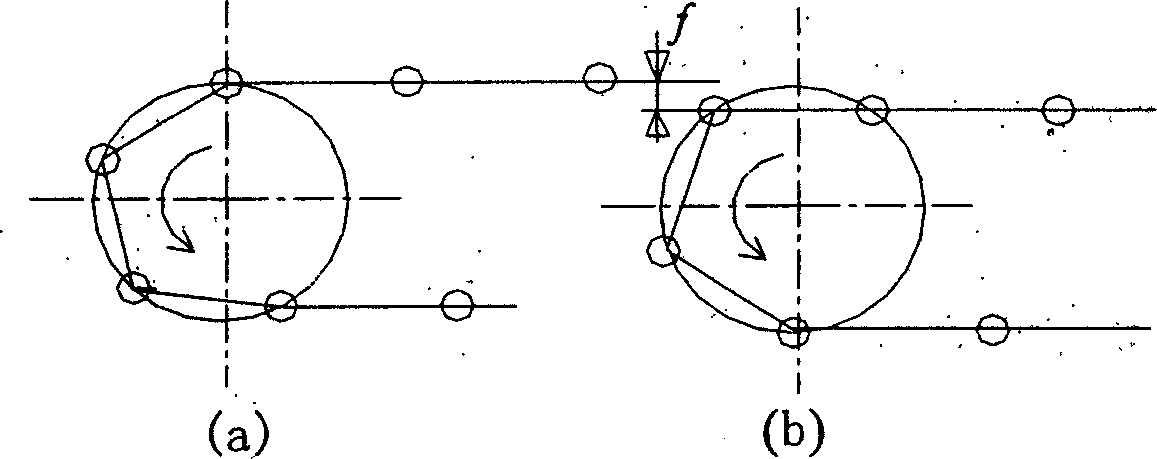

[0025] Embodiment 2: A sprocket with a small pitch and a small number of teeth used for air distribution transmission between a motorcycle crankshaft and a camshaft. Figure 7 It is the sprocket tooth profile curve. The sprocket single-tooth single-side tooth profile is composed of 1, 2 and 3 parts and three sections of curves, of which 1 and 3 parts are two sections of arcs, and 2 sections are slightly convex curves. The sprocket tooth shape symmetry. Figure 6 sprockets shown with image 3 , 4 The toothed chain of the structure shown in the diagram realizes meshing, the pitch of the chain is 6.35 mm, and the pitch of the sprocket is 6.31 mm. The toothed chain and sprocket have low noise and long life, suitable for high-speed transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com