Laser induced fluorescence and light absorption bifunction detecting microflow controlled electrophoresis ehip

A laser-induced fluorescence and electrophoresis chip technology, which is applied in fluorescence/phosphorescence, color/spectral characteristic measurement, measurement devices, etc., can solve the problems of single function and complex structure of optical detection system, and achieves ingenious design and simple operation of optical path. , the effect of benefiting the resolution and detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

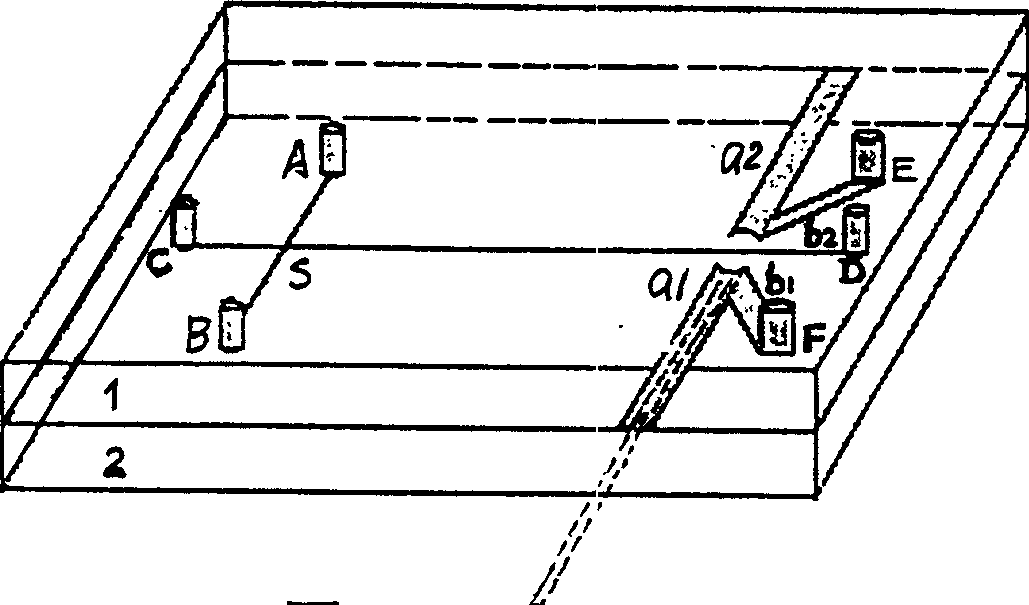

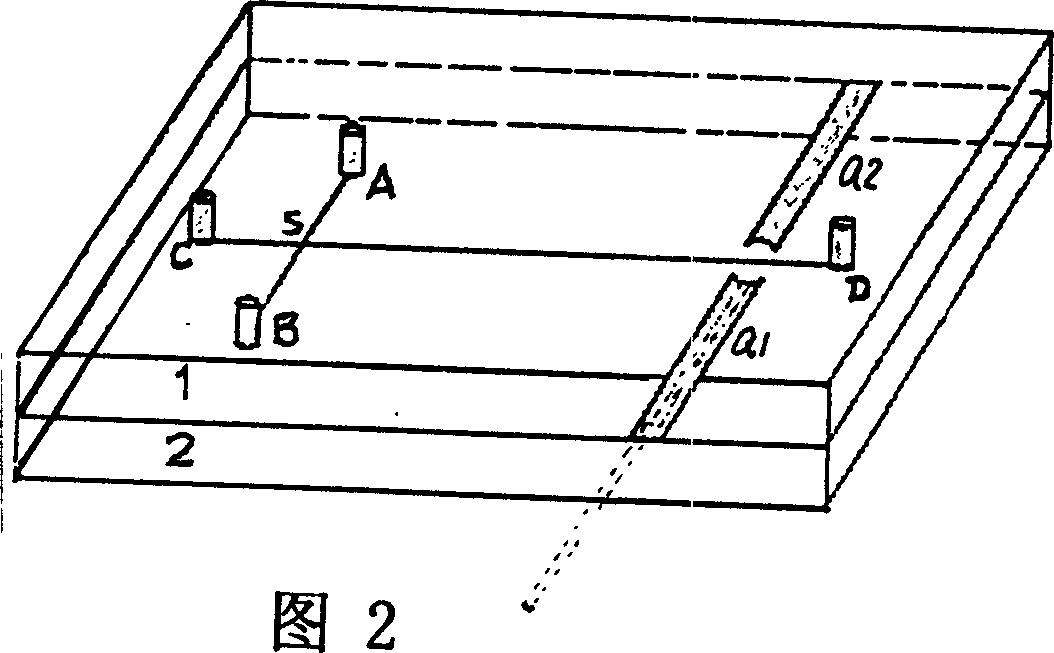

[0059] Example 1: Fabrication of fiber-coupled microfluidic electrophoresis chip made of glass

[0060] 1. Fabrication of chip substrate 2:

[0061] The size design of the microchannel on the mask film: the width of the fluid channel is 40 μm; the width of the fiber channel is 60 μm; the distance d between the fiber channel and the separation channel CD is 200 μm;

[0062] Place the mask film on a 63mm×63mm×1.5mm uniform chrome plate, expose to ultraviolet rays for 180 seconds (wavelength 365nm), develop in the developer for 100 seconds, and dry at 100°C for half an hour;

[0063] Corrode the chromium film with a chromium film etching solution (cerium sulfate: perchloric acid: water=50 grams: 15 milliliters: 300 milliliters) at room temperature, then rinse it with high-purity water, and dry it;

[0064] The channel size on the chromium plate was measured by digital microscope photography: the width of the fluid channel is 60 μm; the width of the optical fiber channel is 90 μm...

Embodiment 2

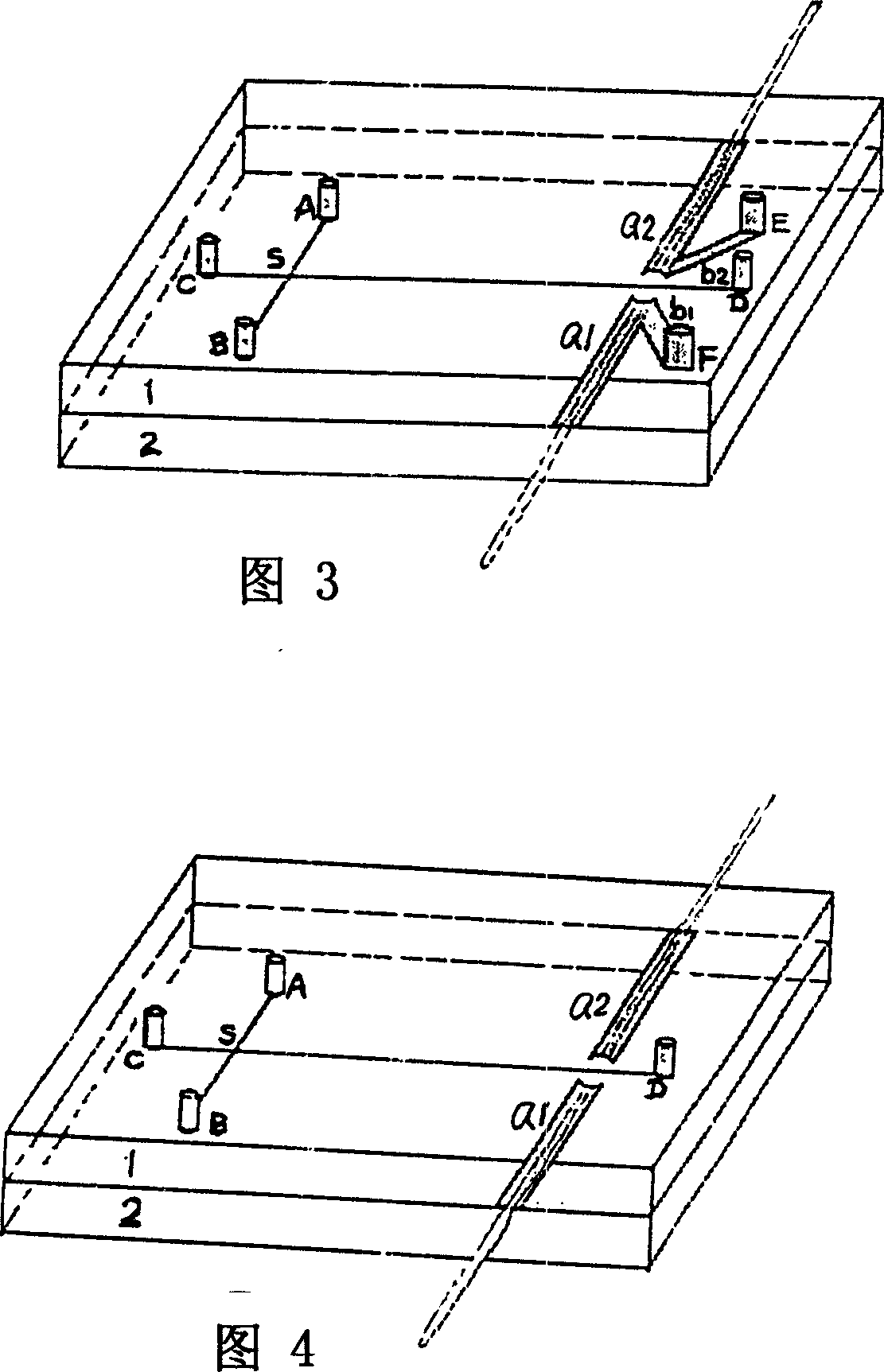

[0074] Example 2: Fabrication of PMMA laser-induced fluorescence and light absorption dual-function detection microfluidic electrophoresis chip

[0075] 1. Design of the glass positive template mask film (substrate and cover sheet): the width of the microfluidic channel on the positive template mask of the chip substrate is 120 μm; the width of the optical fiber channel on the positive template mask of the chip cover plate is 250 μm, The distance is 240 μm.

[0076] 2. Production of substrate positive template: place the chip substrate mask film on a 63mm×63mm×1.5mm uniform chrome plate, expose to ultraviolet rays for 5 minutes (wavelength 365nm), develop in the developer for 100 seconds, and bake at 100°C half an hour. The chromium film was etched with a chromium film etching solution (cerium sulfate: perchloric acid: water = 50 g: 15 ml: 300 ml) at room temperature, and then rinsed with water. With 0.2M HF / 0.2M NH 4 F etchant was used for etching, the rate was about 4 μm / ...

Embodiment 3

[0081] Example 3: Fabrication of a microfluidic electrophoresis chip for dual-function detection of laser-induced fluorescence and light absorption made of PDMS

[0082] 1. The design of the glass positive template mask film (substrate and cover sheet): the width of the microfluidic channel on the positive template mask of the substrate is 120 μm; the width of the optical fiber channel on the positive template mask of the cover plate is 250 μm, and the distance between the two optical fiber channels 240μm;

[0083] 2. Production of glass substrate positive template: place the substrate mask film on a uniform chrome plate of 63mm×63mm×1.5mm, expose to ultraviolet rays for 5 minutes (wavelength 365nm), develop in the developer for 100 seconds, and bake at 100°C half an hour. The chromium film was etched with a chromium film etching solution (cerium sulfate: perchloric acid: water = 50 g: 15 ml: 300 ml) at room temperature, and then rinsed with water. With 0.2M HF / 0.2M NH 4 F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com