Method for nano plant Chinese medicine

A nanotechnology and traditional Chinese medicine technology, which is applied in the direction of medical formula, medical preparations containing active ingredients, powder delivery, etc., can solve the problems of nano-plant traditional Chinese medicines that have not yet been discovered, and achieve great pharmaceutical application value, no loss of active ingredients, Effect of Improving Dissolution Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

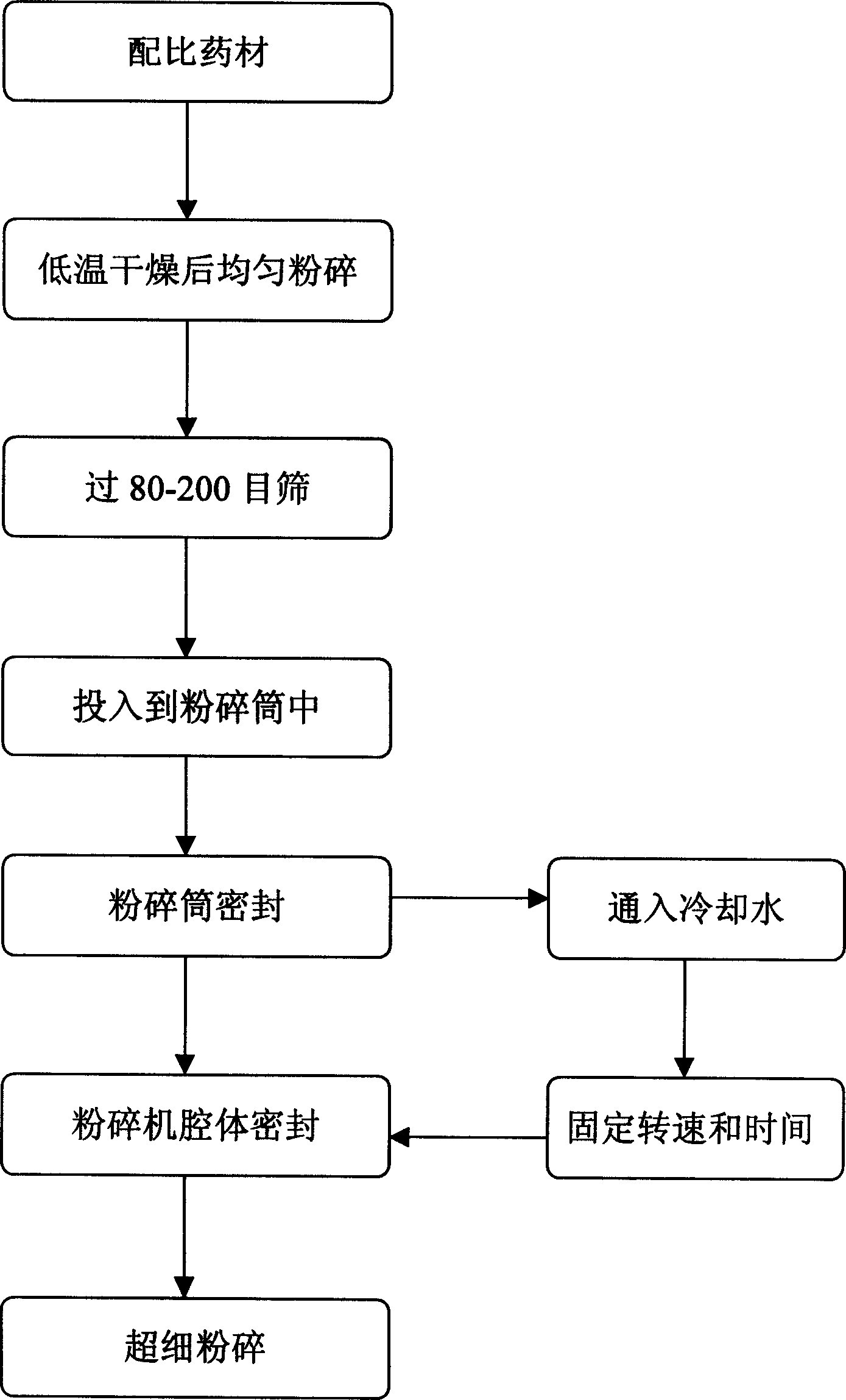

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Preparation of nano Liuweidihuang powder by wet method. According to the provisions of the Chinese Pharmacopoeia, the original medicine of Liuwei Dihuang is formulated: Rehmannia glutinosa 160g, Cornus officinalis 80g, Chinese yam 80g, Poria cocos 60g, Moutan cortex 60g, Alisma 60g. evenly distributed.

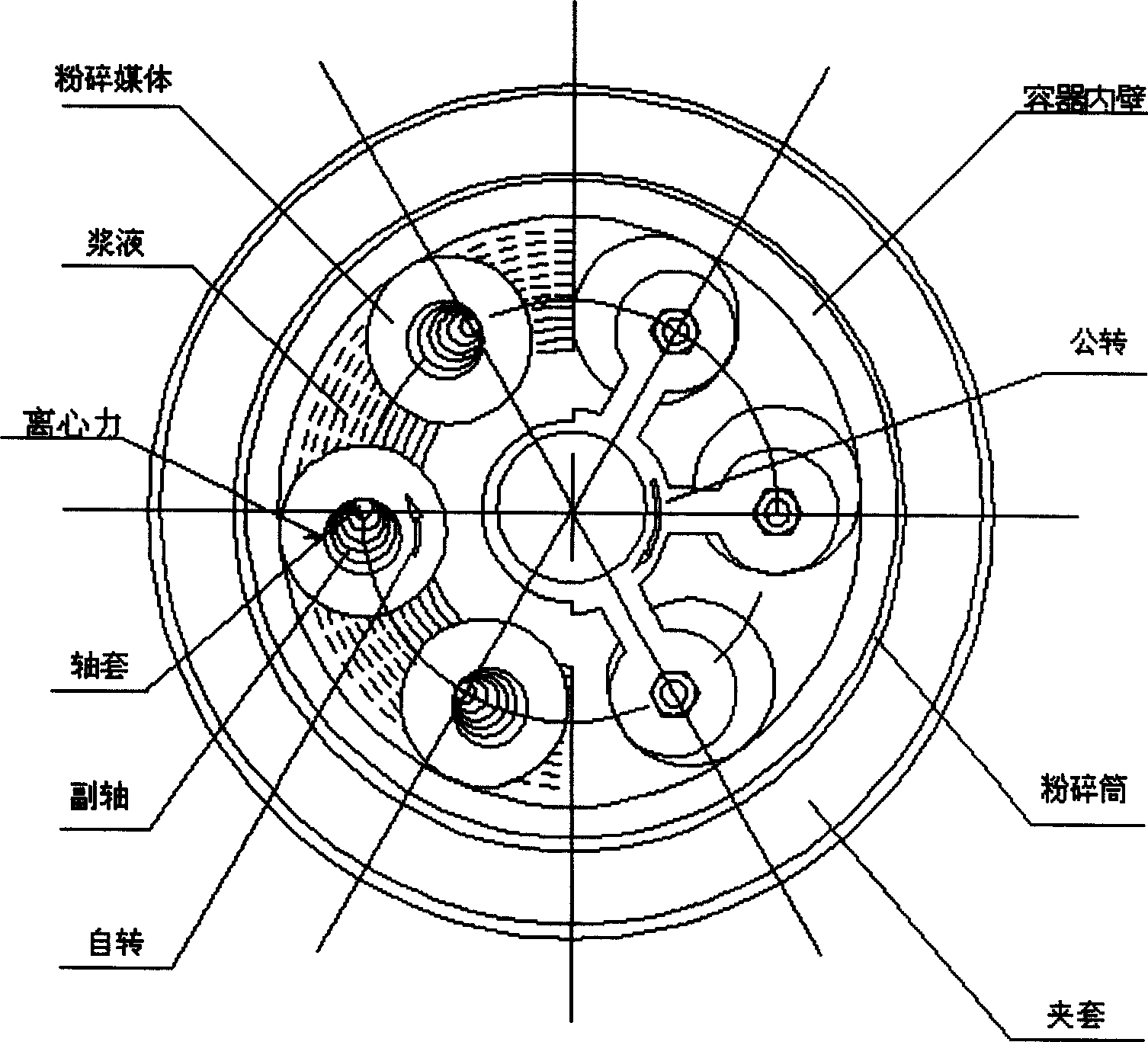

[0029] Add distilled water as a dispersant to Liuweidihuang fine powder, the weight ratio of traditional Chinese medicine fine powder to distilled water is 1:20, after dispersing evenly, soak for 24 hours, and then transfer to a fully enclosed high-speed centrifugal shear ultrafine pulverizer for pulverization In the barrel, the knob is used to control the rising of the crushing barrel and the main shaft is sealed, and the dispersion of distilled water makes the raw material powder distribute in the gap of the ceramic crushing ring. The jacket of the crushing cylinder is connected with cooling water to control the working temperature at room temperature. Af...

Embodiment 2

[0037]Example 2: Preparation of nano Liuweidihuang powder by wet method. Add distilled water as a dispersant to Liuweidihuang fine powder, the weight ratio of traditional Chinese medicine fine powder to distilled water is 1:25, after dispersing evenly, soak for 12 hours, and then transfer to a fully enclosed high-speed centrifugal shear ultrafine pulverizer for pulverization In the cylinder, the jacket of the crushing cylinder is connected with cooling water to control the working temperature at room temperature. After sealing the crushing cylinder, carry out continuous crushing, the spindle speed is 800 rpm, and the crushing time is 90 minutes. The particle size of the ultra-finely pulverized powder is 200nm as measured by a ZetaPALS light scattering particle size distribution analyzer.

Embodiment 3

[0038] Example 3: Preparation of nano Liuweidihuang powder by wet method. Add distilled water as a dispersant to Liuweidihuang fine powder, the weight ratio of traditional Chinese medicine fine powder to distilled water is 1:30, after dispersing evenly, soak for 1 hour, and then transfer to a fully enclosed high-speed centrifugal shear ultrafine pulverizer for pulverization In the cylinder, the jacket of the crushing cylinder is connected with cooling water to control the working temperature at room temperature. After sealing the crushing cylinder, carry out continuous crushing, the spindle speed is 2400rpm, and the crushing time is 30 minutes. The particle size of the powder after ultrafine pulverization is 134nm as measured by a ZetaPALS light scattering particle size distribution analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com