Process for preparing compound coemzyme medicine and its compound coemzyme medicine and clinical use

A technology of coenzyme and yeast cells, applied in the field of medicine, can solve the problems of the scope of influence, inactivation of coenzyme, degradation and destruction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

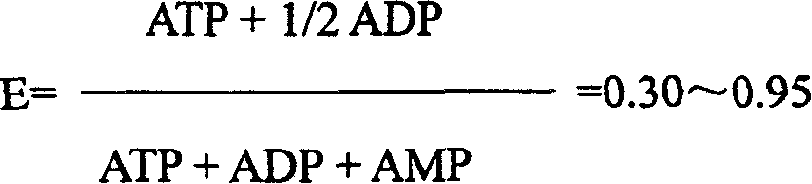

Method used

Image

Examples

Embodiment 1

[0019] Fresh baker’s yeast is added with 5 times PH4.0 0.01M acetic acid buffer solution to make yeast cell suspension; use a high-pressure homogenizer to break the yeast cells at a pressure of 100Mpa to maintain the cell suspension below 20°C; the broken yeast is under 5°C The cell suspension was centrifuged in freezing and centrifuged at a speed of 20000 CPM for 60 minutes to obtain a clear solution; adsorbed on activated carbon, desorbed with a 40% ammonia ethanol solution containing 2% ammonia, adjusted to pH 8.0 with the desorbed solution, and applied to Ambrite IRC50 ion exchange column with pH 8.5 , 0.02M phosphoric acid solution for elution; the eluate is ultrafiltered with an ultrafilter with a cut-off molecular weight of 8000, and the filtrate is concentrated by nanofiltration to remove H 2 O, concentrate to 1 / 10 of the original volume, adjust the pH to 3.5, add 5 times the volume, precipitate with cold acetone at -10°C, collect the precipitate, dissolve in pyrogen-free ...

Embodiment 2

[0023] Add 6 times PH3.0, 0.03M acetic acid buffer to fresh brewer's yeast, crush the cells with a high-pressure homogenizer at 70Mpa pressure, maintain the cell crushing liquid below 10°C, centrifuge at 30000 CPM for 45 minutes at 3°C to obtain a clear liquid; Ultrafiltration with an ultrafiltration membrane with a molecular weight cut-off of 8000; activated carbon adsorption, analysis with 40% ammonia ethanol containing 3.0% ammonia; pH of the analysis solution adjusted to 7.5 on Ambrite IRC 50 ion exchange column, with pH 9.0, 0.01M phosphate buffer Elution; the eluate is ultrafiltered through an ultrafiltration membrane with a cutoff molecular weight of 5000; the ultrafiltrate is removed by reverse osmosis 2 O was concentrated to 1 / 5 of the original volume, adjusted to pH 2.5, added 10 times the volume of cold acetone at -15°C, overnight at 0°C, and collected the precipitate the next day. The precipitate is dissolved in pyrogen-free water, the concentration of each component...

Embodiment 3

[0026] Add 8 times the pH4.5, 0.01M acetic acid buffer solution to the fresh edible yeast; use a high-pressure homogenizer to break the yeast cells under a pressure of 150Mpa to maintain the broken solution below 5°C; centrifuge at 35000cpm at 0°C for 30 minutes Obtain the clear liquid; collect the filtrate; the activated carbon absorbs the filtrate and analyzes it with 40% ethanol containing 3.5% ammonia; adjusts the pH of the analysis solution to 9.0, and applies the Ambrite IRC 50 ion exchange column to pH8.0, 0.03M phosphate buffer The eluate is eluted by an ultrafiltration membrane with a cutoff molecular weight of 9000. The ultrafiltrate is concentrated to 1 / 8 of the original volume by reverse osmosis, adjusted to pH 3.0, and added 8 times the volume of cold acetone at -20°C. Collect the precipitate every day. The precipitate is dissolved in pyrogen-free water, the concentration of each component is measured, sterilized, potted, and lyophilized.

[0027] Coenzyme ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com