Quenching agent and method for stub axle

A technology of automobile steering knuckle and quenching agent, which is applied in the direction of quenching agent, heat treatment equipment, furnace, etc., can solve the problem that the steering knuckle of automobile cannot be well satisfied, and achieve the effect of long fatigue life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the preparation of automobile steering knuckle quenching agent stock solution

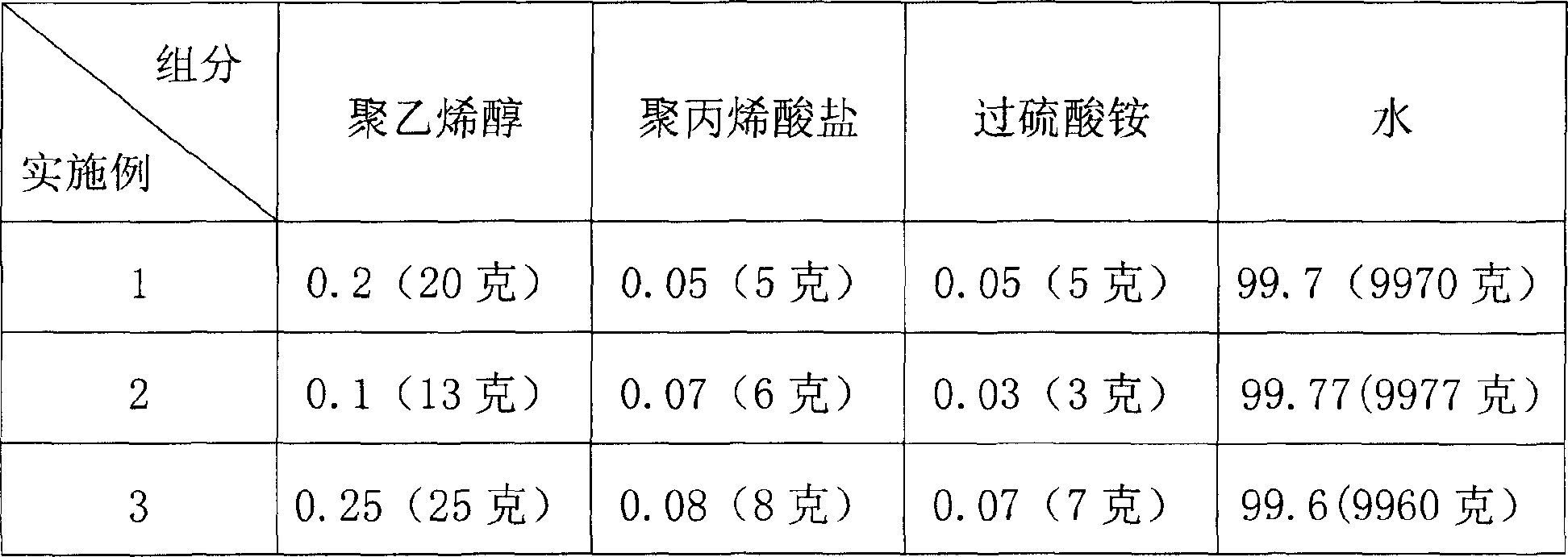

[0012] Take 20 grams of polyvinyl alcohol, 5 grams of polyacrylate, 5 grams of ammonium persulfate, add 9970 grams of water and heat in a furnace until the polyvinyl alcohol, polyacrylate and ammonium persulfate are completely and uniformly dissolved. Then turn off the heat source, and wait for it to cool to room temperature to obtain the quenching agent stock solution. Concrete embodiment formula sees table (content is percentage by weight):

[0013]

Embodiment 2~3

[0014] Embodiment 2~3: the preparation of automobile steering knuckle quenching agent stoste

[0015] The formula of the stock solution is shown in the table above, and the preparation method is the same as in Example 1.

Embodiment 4

[0016] Example 4: 40Cr steel material with an effective thickness of 40 mm for the steering knuckle journal

[0017] The 40Cr steel steering knuckle workpiece is heated to 860°C in the furnace, kept at this temperature and completely homogenized austenite, and then quenched into water containing 0.30% stock solution (refractive index measured by a refractometer is converted into this concentration value) for cooling In the quenching process, the temperature of the quenching agent is controlled to be lower than 50°C by circulating cooling. After about 10 minutes, the workpiece and the quenching agent reach the same temperature, that is, the core of the workpiece is completely cooled. Take the workpiece out of the coolant, and then measure the Rockwell hardness of the transverse section of the journal. The Rockwell hardness from the edge of the journal to the core is 57-52HRC, indicating that the core has been completely hardened, and then through 580-620℃ Tempered at high tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com