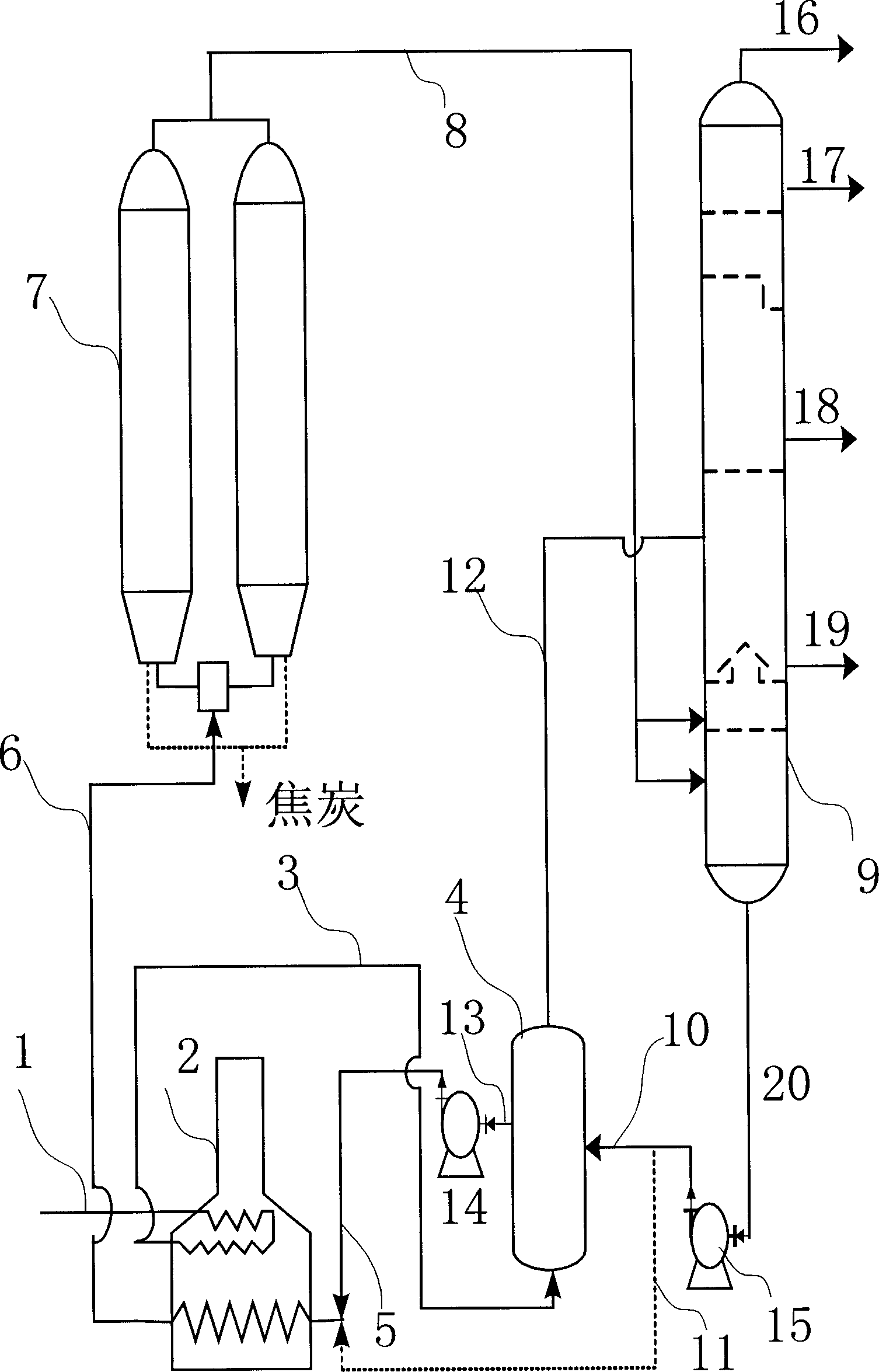

High acid value hydrocarbon oil delayed coking method

A delayed coking method and high acid value hydrocarbon technology, which is applied in cracking, petroleum industry, non-catalytic thermal cracking, etc., can solve problems such as corrosion and fractionation tower corrosion, and achieve the effect of reducing corrosion and prolonging the coking start-up period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Atmospheric residual oil with a total acid value of 6mgKOH / g is heated to 410°C in the convection section and the upper part of the radiation section of the heating furnace, and then enters the reactor for mild thermal cracking reaction. The pressure in the reactor is 0.2MPa, and the residence time is 30min. Sampling and analysis of the flow in the middle and lower part of the radiant section of the heating furnace showed that the total acid value was 0.6 mgKOH / g, and the sampling analysis of the light oil at the top of the reactor had a total acid value of 0.3 mgKOH / g.

Embodiment 2

[0037] The vacuum residue with a total acid value of 4mgKOH / g is heated to 420°C by the convection section and the upper part of the radiation section of the heating furnace, and then enters the reactor for mild thermal cracking reaction. The pressure in the reactor is 0.3MPa, and the residence time is 40min. Sampling and analysis of the flow in the middle and lower part of the radiant section of the heating furnace showed that the total acid value was 0.5 mgKOH / g, and the sampling analysis of the light oil at the top of the reactor had a total acid value of 0.2 mgKOH / g.

Embodiment 3

[0039] Crude oil with a total acid value of 12mgKOH / g is heated to 430°C by the convection section and the upper part of the radiation section of the heating furnace, and then enters the reactor for mild thermal cracking reaction. The pressure in the reactor is 0.3MPa, the residence time is 50min, and the upper part of the reactor goes to the heating furnace Sampling and analysis of the flow in the middle and lower parts of the radiation section showed that the total acid value was 1.5 mgKOH / g, and the sampling analysis of the light oil at the top of the reactor had a total acid value of 0.6 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com