Preparation method of plant origion alcohrl soluble protein three dimentional support

A plant-derived, gliadin technology, applied in medical science, prosthesis, surgery, etc., can solve the problems of long preparation cycle and low porosity, and achieve low immunogenicity, high mechanical strength, and easy-to-obtain raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

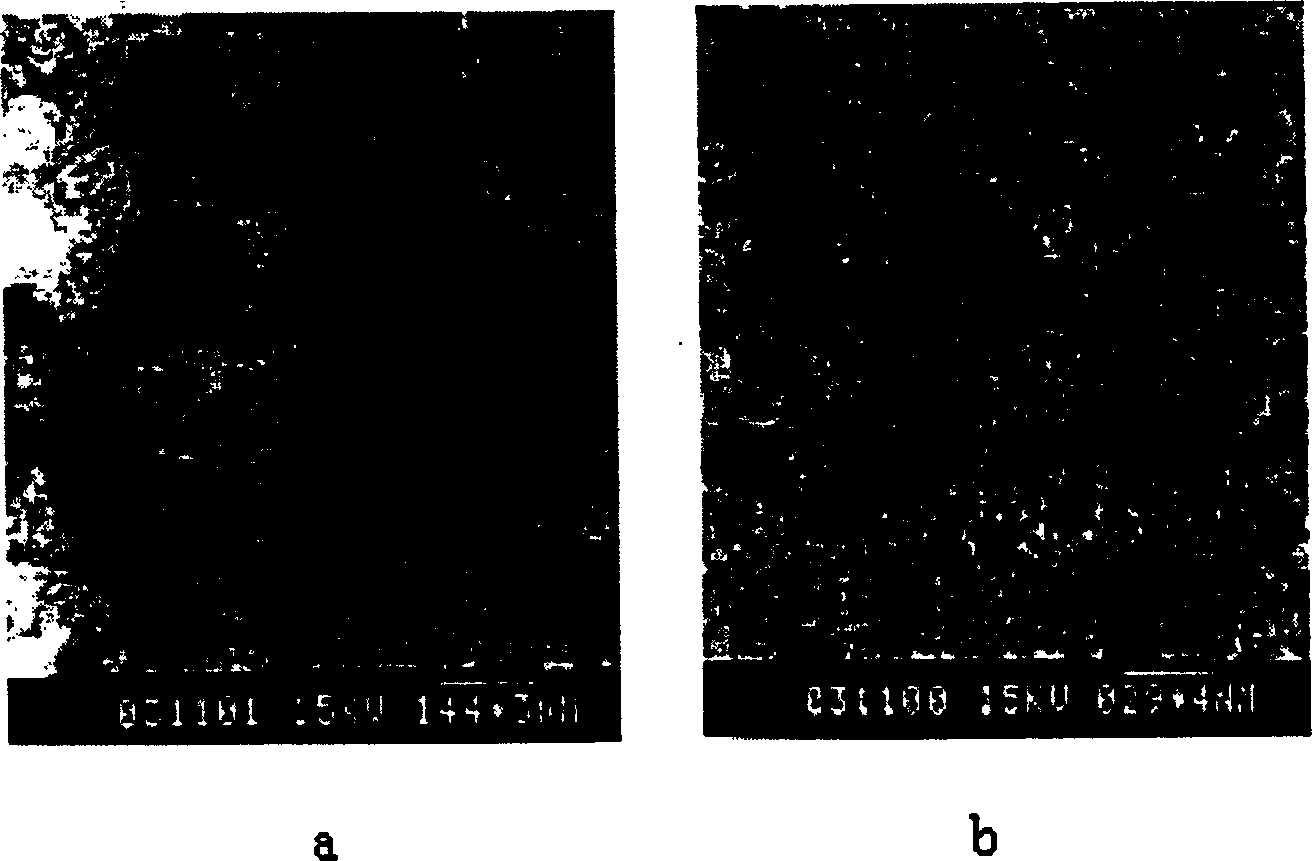

[0018] Mix zein alone or with a pore-forming agent (salt) at a ratio of 1:1 (weight ratio), sieve the salt through sieves of different meshes before mixing, and select a sieve of 70-100 meshes to obtain a pore-forming agent (salt) with a diameter of 76-150 microns. Table salt granules. Then put the mixture into a 10ml small beaker (2g / beaker), place it in an 80°C wet box to incubate after ultraviolet sterilization, and cover the mouth of the beaker with absorbent paper to prevent water droplets from directly entering the beaker. Take it out on the 5th day, soak it in 40°C water for 48 hours, then boil it in water at 60°C for 1 hour, and change 2-3 times of deionized water preheated to the predetermined temperature during the boiling process to ensure that the salt is completely dissolved. Then lyophilized and vacuum-dried, the measured compressive modulus was 11 MPa, and the porosity was 68.6%. Scanning electron microscope ultrastructural observation shows that the pore size ...

Embodiment 2

[0020] After mixing zein and pore-forming agent according to the above method, put 1 gram of protein into a cylindrical mold according to the amount of each sample, and take it out after compression molding with a pressure of about 800N. Each sample is placed separately in a container 60 ℃ deionized water in a small beaker to prevent the samples from sticking to each other in the water, and then directly boil it in a constant temperature water bath for 1 hour, and change the preheated deionized water 2-3 times during the boiling process to ensure The salt is completely dissolved. Then lyophilized and vacuum-dried, the measured compressive modulus was 10MPa. Scanning electron microscope ultrastructural observation shows that the pore size distribution is about 300 microns ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com