Preparation method of plant origion alcohrl soluble protein three dimentional support

A plant-derived, gliadin technology, which is applied in medical science, prosthesis, surgery, etc., can solve the problems of long preparation cycle and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

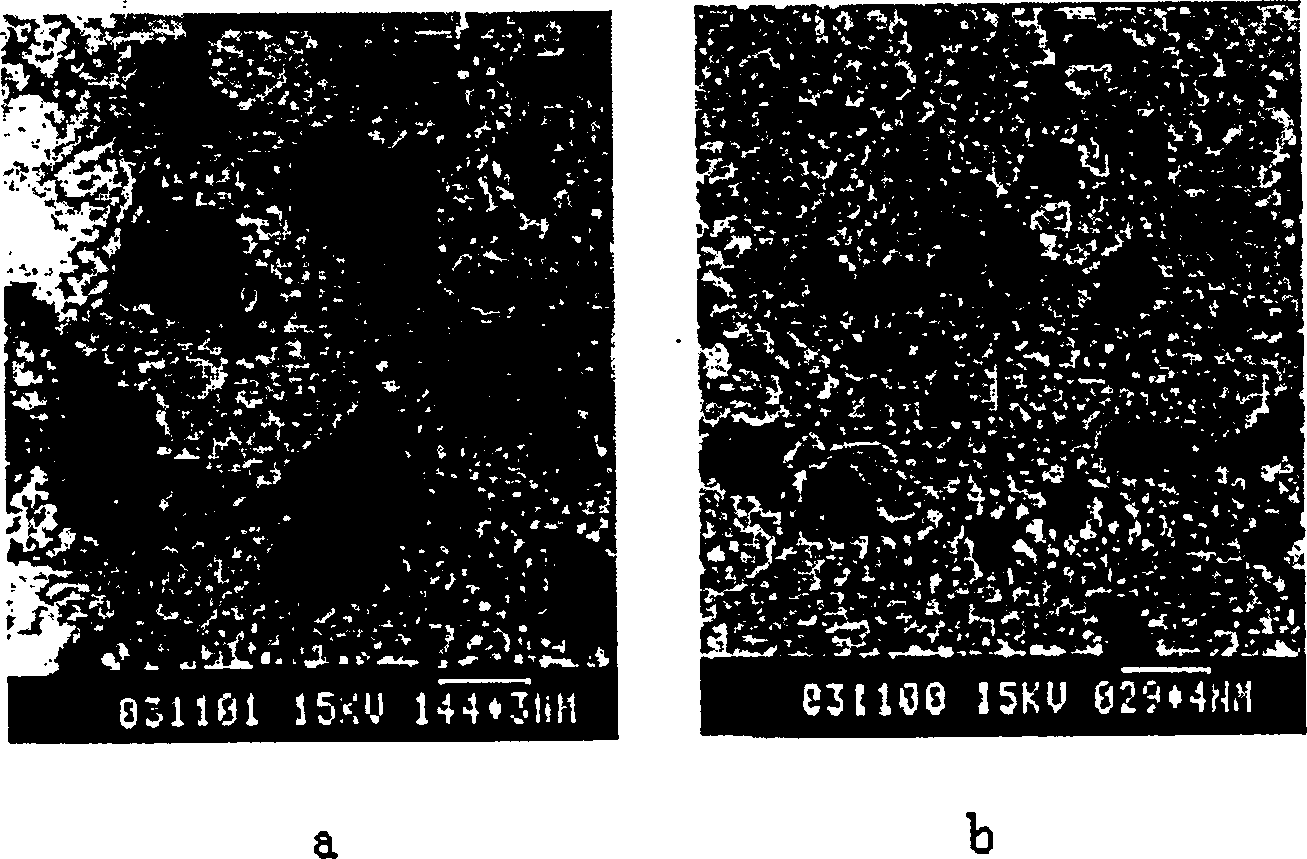

[0018] After mixing the zein and the pore-forming agent according to the above method, put it into a cylindrical mold according to the amount of 1 gram of protein for each sample, compress it with a pressure of about 800N, and then take it out. 60C deionized water in a small beaker to prevent the samples from sticking to each other in the water, and then directly boil in a constant temperature water bath for 1 hour, and change the preheated deionized water 2-3 times during the boiling process to ensure the salt completely dissolved. It was then freeze-dried under vacuum, and the compressive modulus was determined to be 10 MPa. Scanning electron microscope ultrastructural observation shows that the pore size distribution is about 300 microns ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com