Acrylic ester modifier and preparation and use in bisphenol A poly carbonate

A technology of acrylates and modifiers, applied in the field of acrylate modifiers prepared from organic-inorganic hybrid materials, can solve the problem of reducing PC heat resistance, reducing optical properties, reducing PC tensile strength and bending mold It is easy to replace the formula, the process is simple, and the performance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

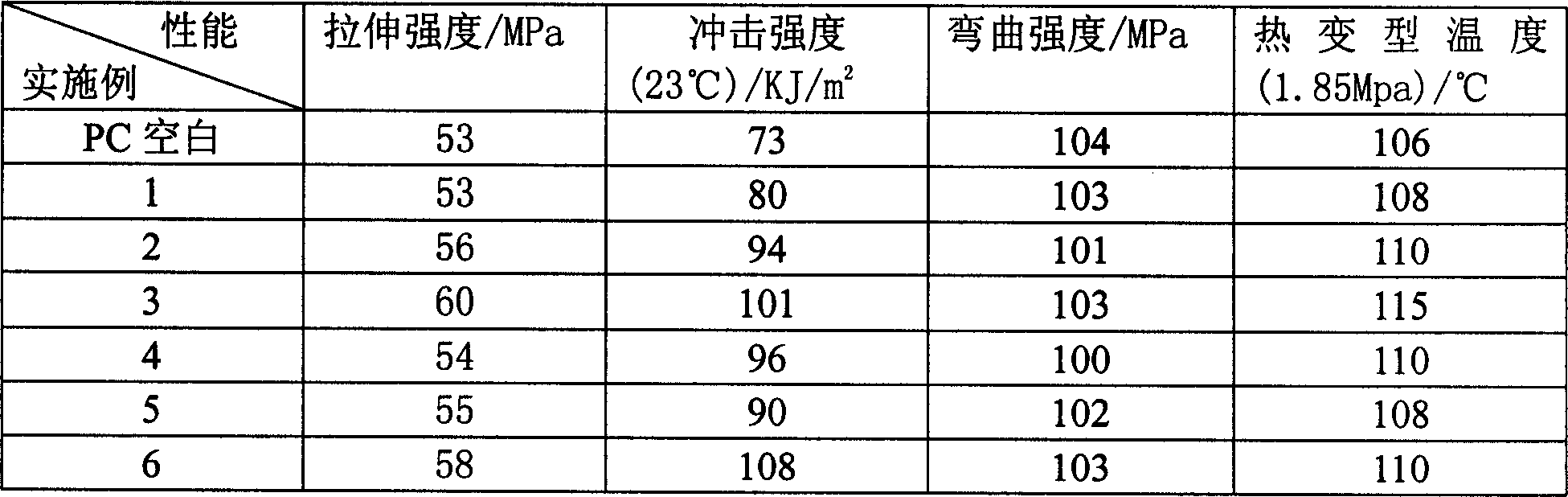

Examples

Embodiment 1

[0033] Firstly, dry the nano-silica in an oven at 105°C for 2 hours, then add silane coupling agent KH-570 and xylene to the dried nanoparticles, stir in the air for 20 minutes, protect with nitrogen, and then place in an oil bath heated to 140°C in medium, stirred, and the reaction temperature was controlled at the reflux temperature of xylene at 140°C. After reacting for 10 hours, the product was left to stand, and after the layers were separated, the lower layer was dried in vacuum to obtain alkylated nano-silica, wherein The weight ratio between each material is:

[0034] Nano silica: KH-570: xylene = 10: 2: 250;

[0035] Then add the alkylated nanoparticles and emulsifier into deionized water, protect with nitrogen, start stirring, and add ammonium persulfate, butyl acrylate and methyl methacrylate dropwise when the temperature rises to 70°C. After the reaction is complete, cool to room temperature, and the emulsion is spray-dried to obtain a white powder, wherein the we...

Embodiment 2

[0039] Firstly, dry the nano-silica in an oven at 105°C for 2 hours, then add silane coupling agent KH-570 and xylene to the dried nanoparticles, stir in the air for 20 minutes, protect with nitrogen, and then place in an oil bath heated to 140°C in medium, stirred, and the reaction temperature was controlled at the reflux temperature of xylene at 140°C. After reacting for 10 hours, the product was left to stand, and after the layers were separated, the lower layer was dried in vacuum to obtain alkylated nano-silica, wherein The weight ratio between each material is:

[0040] Nano silica: KH-570: xylene = 10: 2: 250;

[0041] Then add the alkylated nano-silica and emulsifier into deionized water, protect it with nitrogen, start stirring, and when the temperature rises to 70°C, add ammonium persulfate and methyl methacrylate dropwise, and the reaction is complete After cooling to room temperature, the emulsion was spray-dried to obtain a white powder,

[0042] Wherein the wei...

Embodiment 3

[0045] First, dry the nano-zinc oxide in an oven at 105°C for 2 hours, then add KH-570 and xylene to the dried nanoparticles, stir in the air for 20 minutes, protect with nitrogen, and then heat to 140°C in an oil bath , stirring, the reaction temperature is controlled at the reflux temperature of xylene at 140°C, after 10 hours of reaction, the product is left to stand, and after layering, the lower layer is vacuum-dried to obtain the alkylated nano-zinc oxide, wherein the weight of each material than:

[0046] Nano zinc oxide: KH-570: xylene = 10: 2: 250;

[0047] Then add the alkylated nanoparticles and emulsifier into deionized water, protect with nitrogen, start stirring, and when the temperature rises to 70°C, add ammonium persulfate, 2-ethylhexyl acrylate and methyl Methyl acrylate, after the reaction is complete, is cooled to room temperature, and the emulsion is spray-dried to obtain a white powder, wherein the weight ratio between each material is:

[0048] Wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com