Integrated melt method for crystal growth

A technique for growing crystal and melt method, applied in the field of melt growth and crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 grows sapphire

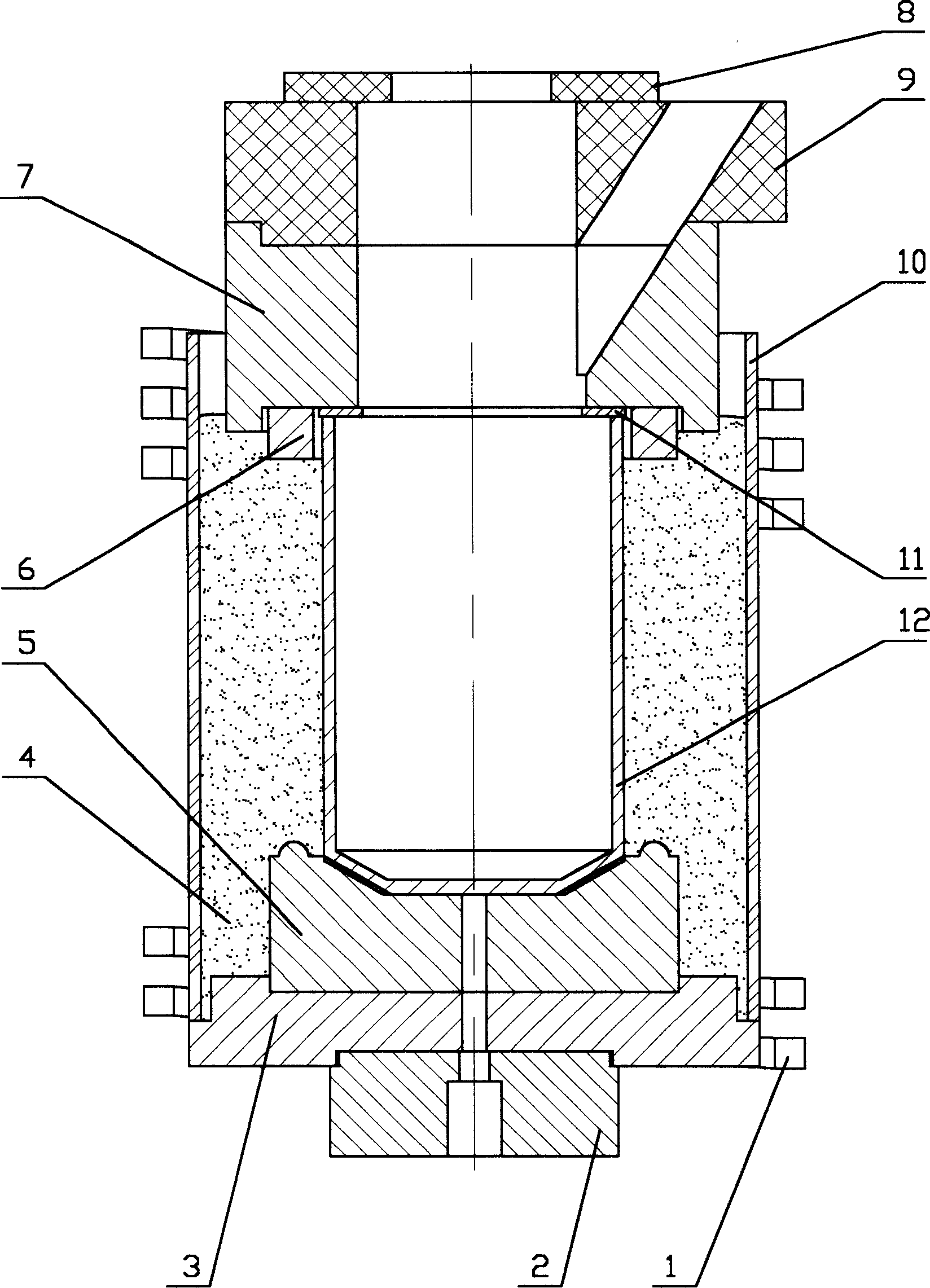

[0026] Use domestic single crystal furnace (such as manufactured by Xi'an University of Technology factory, with computer control, upper load cell), molybdenum crucible, medium frequency induction heating, zirconia insulation material, the specific configuration is as follows figure 1 shown.

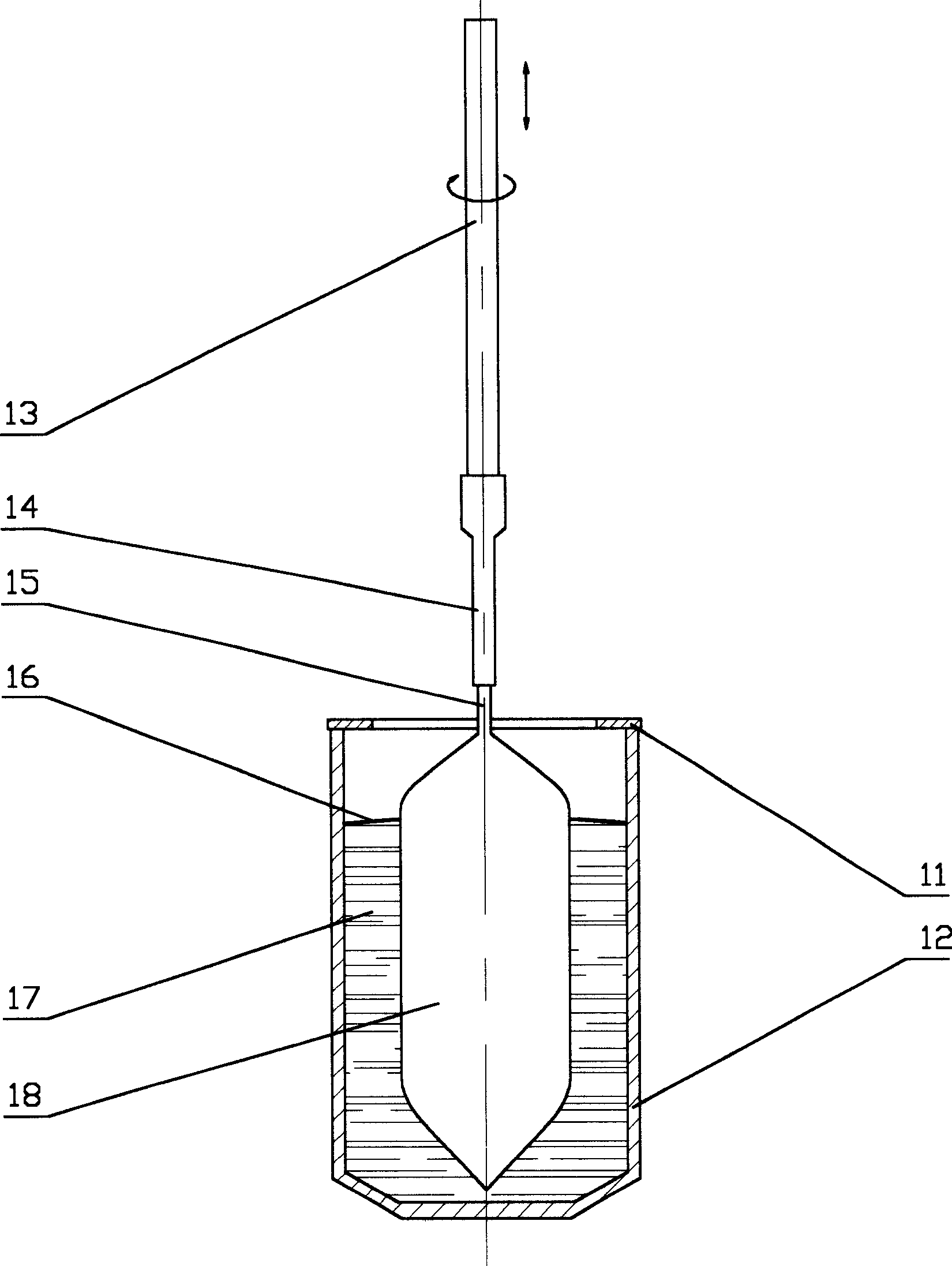

[0027]Put 2,500 grams of sintered alumina into a Φ100mm crucible, vacuumize to 10-2Pa, and then fill with hydrogen to 0.8atm. Heat up and melt, lower the seed rod to preheat the seed crystal, the seed crystal rotates at 30rpm, let the seed crystal touch the liquid surface of the melt, pull it at 3mm / hr after heat balance; close the neck and put the shoulder. After the crystal diameter is about 15mm, gradually reduce the pulling speed and rotation speed, respectively to 1.5mm / hr and 15rpm until the crystal diameter is 30mm, further gradually reduce the pulling speed and rotation speed according to the enlargement of the crystal diameter, and stop pull...

Embodiment 2

[0033] Example 2 Growth of chromium-doped ruby

[0034] With the same steps and equipment as in Example 1, 2500 grams of alumina and 3.0 wt% chromium oxide according to the total amount were put into a molybdenum crucible for growth. The difference is that the seeding shouldering speed is gradually changed from 2.5 to 1.0mm / hr, and the rotation speed is kept at 10rpm. A ruby with excellent quality is obtained, and the light extraction efficiency reaches more than 1.0%.

Embodiment 3

[0035] Example 3 Growth of titanium-doped sapphire

[0036] With the same steps and equipment as in Example 1, 2500 grams of alumina and 0.2wt% titanium oxide according to the total amount were put into a crucible for growth. The difference is that the iridium crucible and iridium crucible cover are used, the gas filled is nitrogen, the seeding shoulder speed is gradually changed from 2.5 to 1.0mm / hr, and the rotation speed is kept at 10rpm. Sapphire with excellent quality is also obtained, with low dislocation density, low scattering, high structural integrity, and optical uniformity Δn=9×10-7. The method of measuring the length of 20mm titanium sapphire crystal by double optical path and light incident on the surface of the crystal at Brewster's angle, the FOM value of the crystal is determined to be 150.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dislocation density | aaaaa | aaaaa |

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com