Method and apparatus for making fluidic ice

A fluid ice and fluid technology, applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems of large irreversible loss in the refrigeration system, large heat transfer temperature difference in the ice making process, and low thermodynamic efficiency, so as to save equipment The effect of cost and operating power consumption, good adaptability of ice making capacity, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

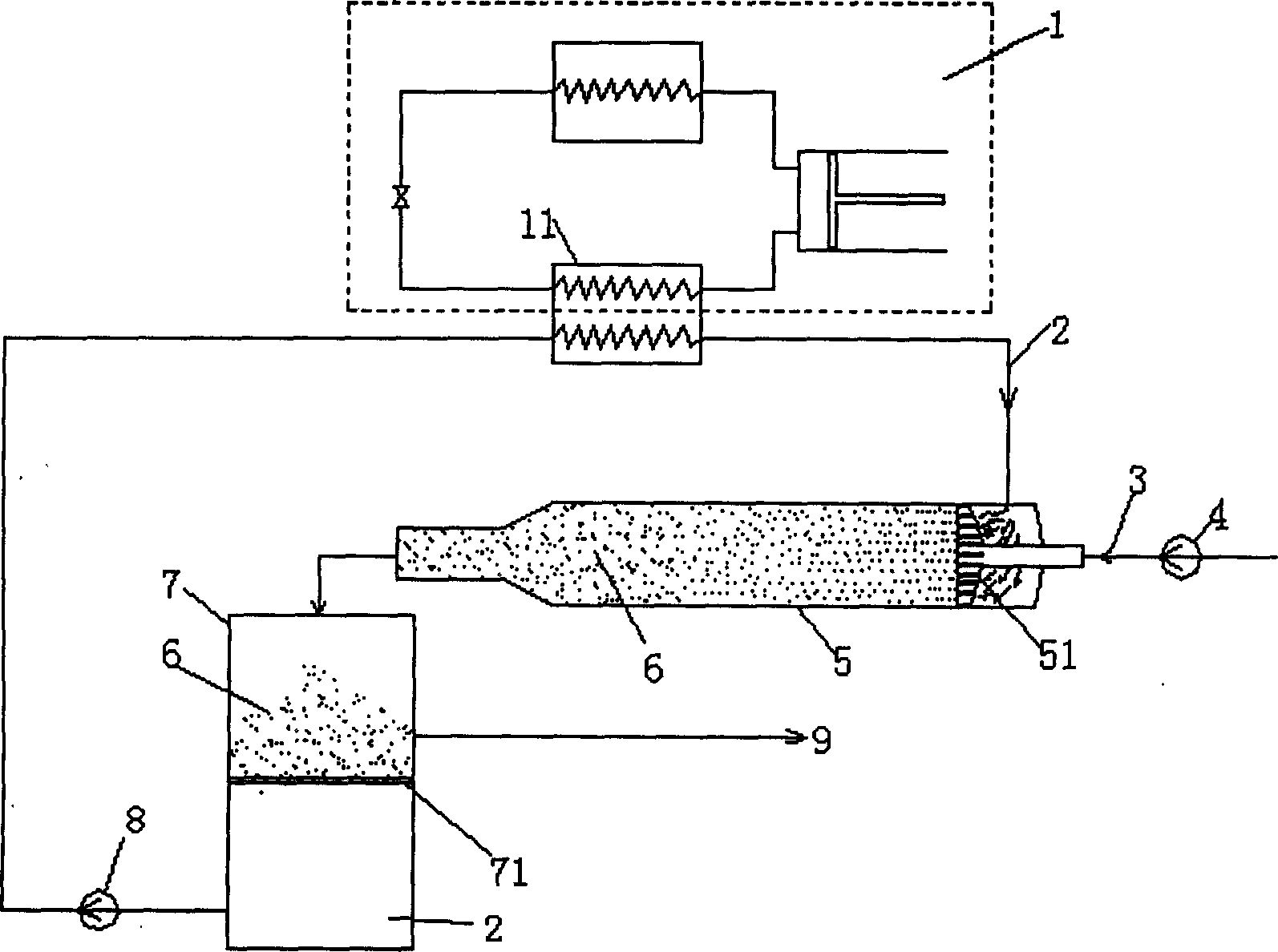

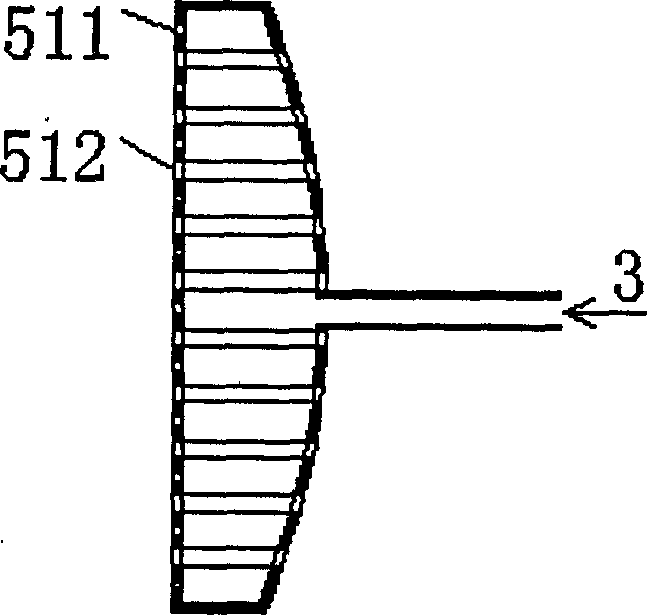

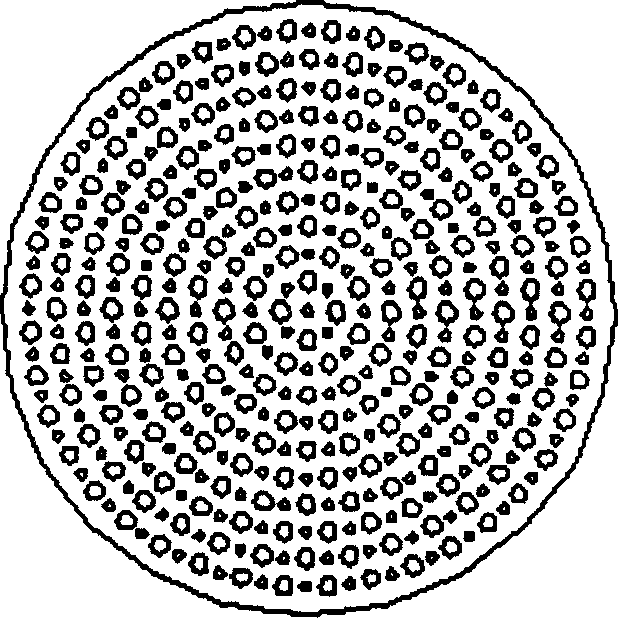

[0026] The present invention proposes a brand-new high-efficiency ice-making method: first, the cooling medium of the fluid is cooled below 0°C through the evaporator, and the ice-making water is sprayed into the cooling medium of the cooled fluid through the nozzle to form ice particles and The mixed fluid of the cooling medium of the fluid sprays water into the cooling medium through the nozzle located in the cooling medium, and the water droplets directly contact the cooling medium for heat exchange, without heat transfer through the metal surface, and the heat transfer intensity is large. During the flow, the water droplets are cooled by the surrounding low-temperature cooling medium and freeze into ice particles. The size of ice particles can be adjusted through the atomization nozzle and atomization pressure. The time required for water droplets to freeze into ice particles mainly depends on the temperature of the cooling medium and the size of the water droplets. For exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com