Impregnated barium tungsten cathode based on tungsten fibre and its preparation method

A barium tungsten cathode and tungsten fiber technology, applied in the field of barium tungsten cathode, can solve the problems of complex process, not long life, and insufficient emission current of impregnated barium tungsten cathode, achieve good process repeatability and stability, and shorten production cycle , The effect of facilitating electron emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

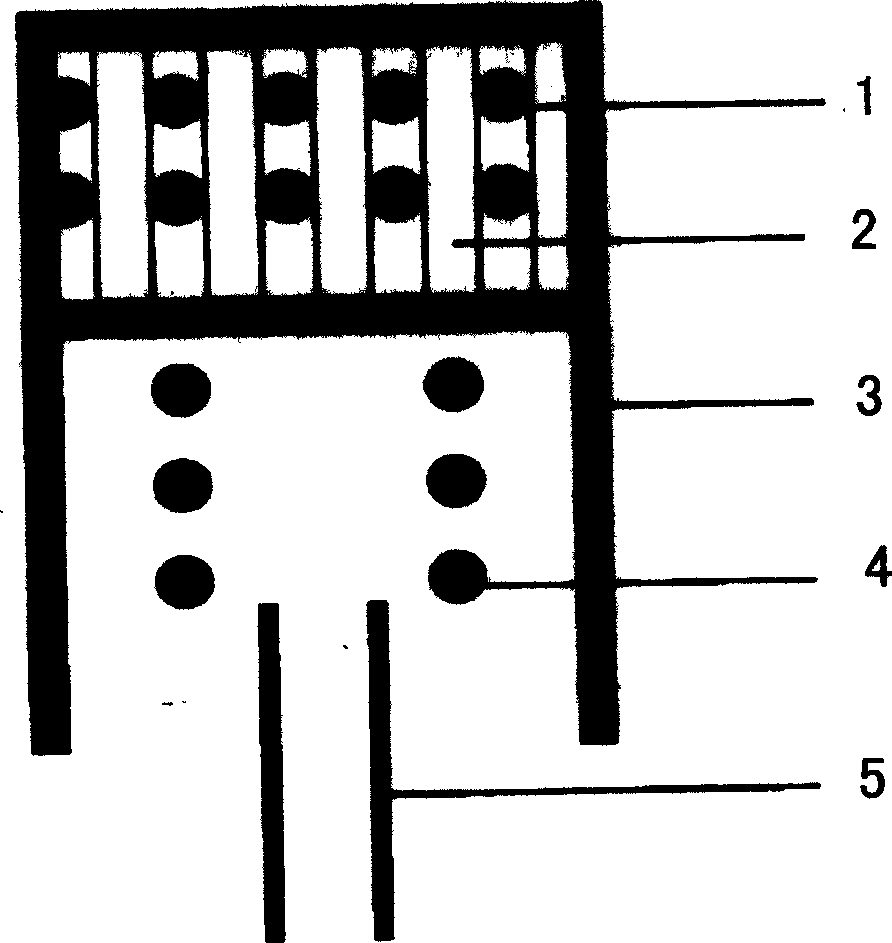

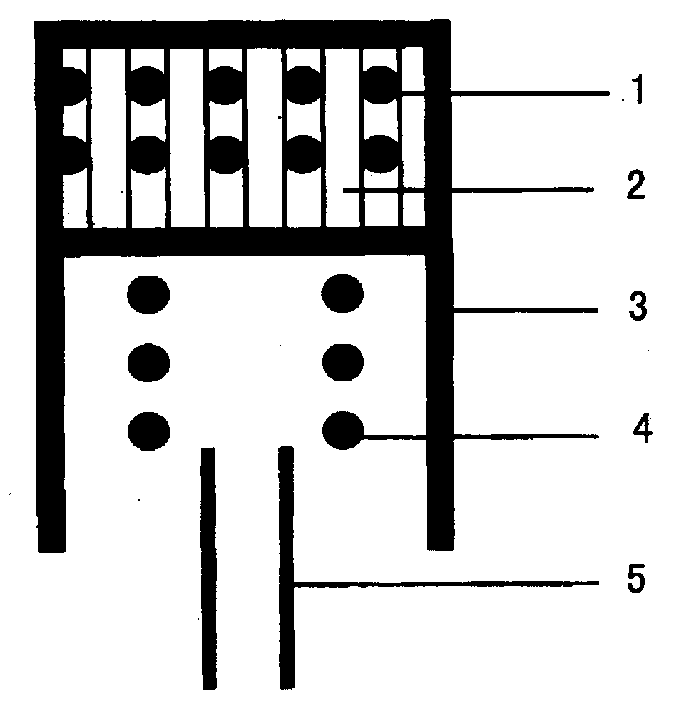

[0021] The impregnated barium tungsten cathode provided by the invention is composed of 10-30% tungsten fiber and 70-90% tungsten powder by weight, and aluminates are impregnated in the pores.

[0022] The method for preparing the above-mentioned impregnated barium tungsten cathode provided by the present invention is:

[0023] 1) Micro-particles, high-purity tungsten powder and high-strength, high-temperature-resistant tungsten fiber are used, and the tungsten powder and tungsten fiber are respectively placed in a 1300°C hydrogen furnace for annealing to thoroughly purify and enhance their plasticity.

[0024] 2) Take 20% tungsten fiber and 80% tungsten powder by weight, mix and grind the two materials and make all fiber ports have a certain directionality to ensure uniformity. The mixture was pressed into a flat-topped cathode body using a die containing a cylinder of molybdenum. The flat top cathode body has a diameter of 2-5mm and a thickness of 1-4mm. The flat top catho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com