Zinc-air cell air diffusion electrode pore-forming method and its pore-forming agent

A zinc-air battery and air diffusion technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of air diffusion electrode appearance and internal structure damage, damage to air diffusion electrode quality and performance, and high average cost of electrodes , to achieve the effect of easy control of size and distribution, uniform size and low average cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

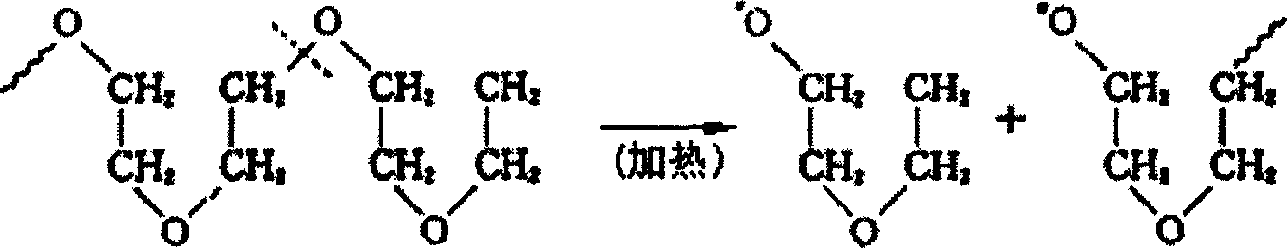

Method used

Image

Examples

Embodiment 1

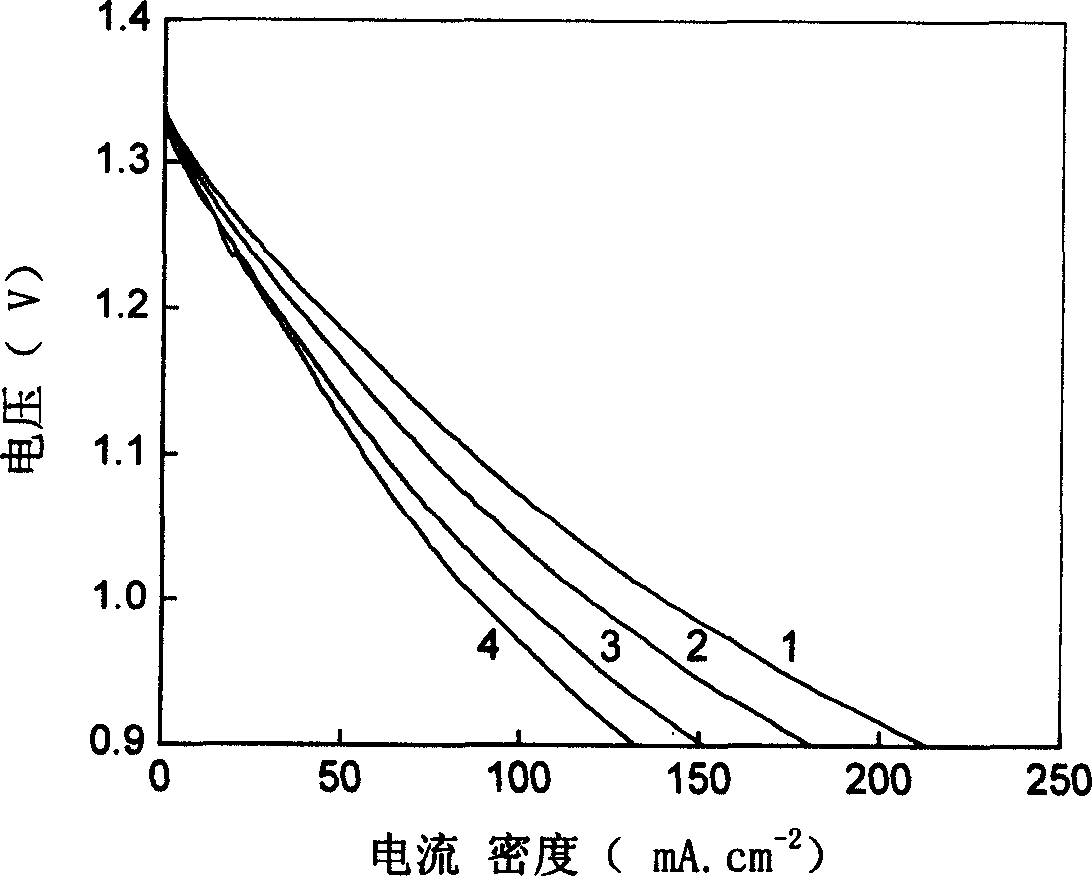

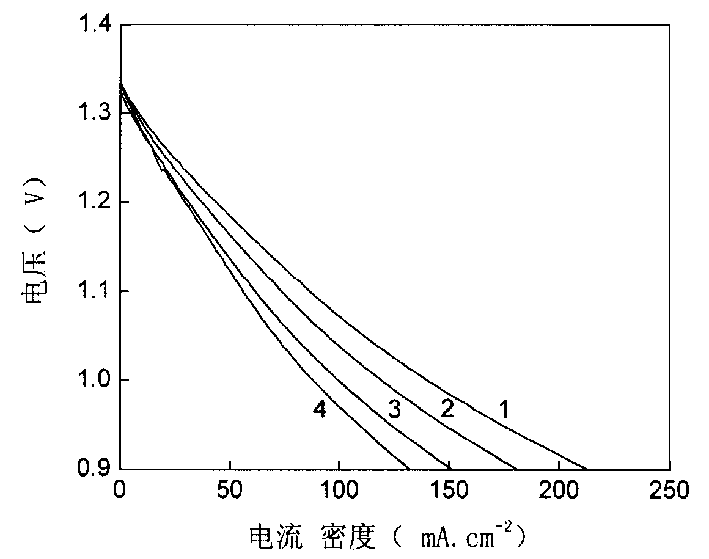

[0044] 16wt% carbon black, 16wt% acetylene black, 32wt% catalyst, 32wt% (to solid content) binder, 4wt% pore-forming agent ammonium oxalate etc. are mixed with an appropriate amount of dispersant ethanol, Heat and stir at 50°C until a paste is formed, and then roll-form it to obtain a catalytic membrane. Mix 30wt% acetylene black, 66wt% (to solid content) binder, 4wt% pore-forming agent ammonium oxalate, etc., with an appropriate amount of dispersant ethanol, heat and stir at 50°C until a paste is formed Roll forming to obtain a waterproof and breathable membrane. According to the sequence of catalytic membrane, waterproof breathable membrane and foamed nickel alloy current collector from inside to outside, the three are laminated and rolled into a cylindrical air diffusion electrode. The air diffusion electrode was dried at 70°C for 30 min, and the thermal decomposition method was used to make pores.

[0045] The catalyst used is LiMn with spinel crystal structure 1.99 co ...

Embodiment 2

[0048] 12wt% carbon black, 12wt% acetylene black, 25wt% catalyst, 25wt% (to solid content) binding agent, 26wt% pore-forming agent ammonium bicarbonate etc. are mixed with an appropriate amount of dispersant ethanol, Heat and stir at 70°C until a paste is formed, and then roll-form it to obtain a catalytic membrane. Mix 25wt% acetylene black, 50wt% (relative to solid content) binder, 25wt% pore-forming agent ammonium bicarbonate, etc., with an appropriate amount of dispersant ethanol, heat and stir at 70°C until a paste is formed Press molding to obtain a waterproof and breathable membrane. According to the sequence of catalytic membrane, waterproof breathable membrane and nickel mesh current collector from the inside to the outside, the three are laminated and rolled into a cylindrical air diffusion electrode. The air diffusion electrode was dried at 250°C for 5 minutes, and the thermal decomposition method was used to make pores.

[0049] The catalyst used is LiMn with spi...

Embodiment 3

[0052] 13wt% carbon black, 13wt% acetylene black, 26wt% catalyzer, 26wt% (to solid content) binding agent, 22wt% pore-forming agent ammonium carbonate etc. are mixed with an appropriate amount of dispersant ethanol, at 55 Heating and stirring at ℃ until a paste is formed, and then roll forming to obtain a catalytic membrane. Mix 26wt% acetylene black, 55wt% (relative to solid content) binder, 19wt% pore-forming agent ammonium carbonate, etc., with an appropriate amount of dispersant ethanol, heat and stir at 55°C until a paste is formed, then roll-press Molded to obtain a waterproof and breathable membrane. According to the sequence of catalytic membrane, waterproof breathable membrane and foamed nickel current collector from inside to outside, the three are laminated and rolled into a cylindrical air diffusion electrode. The air diffusion electrode was dried at 110° C. for 25 minutes, and the thermal decomposition method was used to make pores.

[0053] The catalyst used is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge current density | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com