Cationic-type oligo-surface active agent and preparing method thereof

A surfactant, cationic technology, applied in the field of cationic oligomeric surfactants and their preparation, can solve the problems of restricting the promotion and application of oligomeric surfactants, limited research and development, and expensive, etc. effect of cluster concentration, high surface/interfacial activity, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

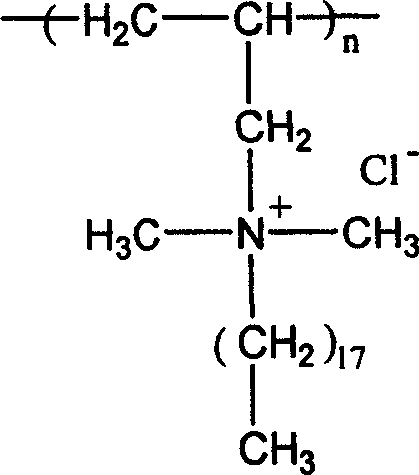

[0035] Example 1: Accurately weigh 148.5g (0.5mol) of octadecyldimethylamine, 38.3g (0.5mol) of propylene chloride, and 150g of absolute ethanol in a 500ml reactor, heat it to 40-50°C in an airtight manner, and stir React for 8 hours. The reaction mixture was taken out, and the solvent ethanol was distilled off under reduced pressure to obtain a light yellow wax. After soaking in anhydrous ether, a white precipitate precipitated out. After filtering and drying, the product obtained is octadecyl dimethyl allyl ammonium chloride (ODMAAC). Prepare octadecyl-dimethyl-allyl ammonium chloride with distilled water into an aqueous solution with a concentration of 15% by mass in a reaction kettle, stir and heat up to 60-80°C. Then add sodium sulfite and potassium persulfate initiator solution. The reaction was completed quickly and separated into two layers, the upper layer was a white viscous paste, and the lower layer was an aqueous solution. The upper white paste was taken out a...

Embodiment 2

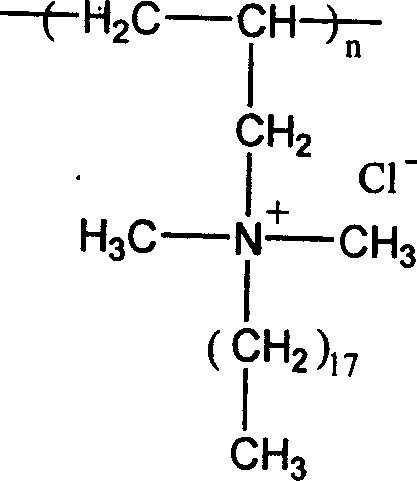

[0036] Example 2: Prepare octadecyl-dimethyl-allyl ammonium chloride with distilled water into an aqueous solution with a concentration of 30% by mass in a reaction kettle, stir and heat up to 60-80°C. Then add sodium sulfite and potassium persulfate initiator solution. The reaction was completed quickly and separated into two layers, the upper layer was a white viscous paste, and the lower layer was an aqueous solution. The upper white paste was taken out and dried to obtain a white solid (PODMAAC-2). The overall yield of product was 89.6%.

Embodiment 3

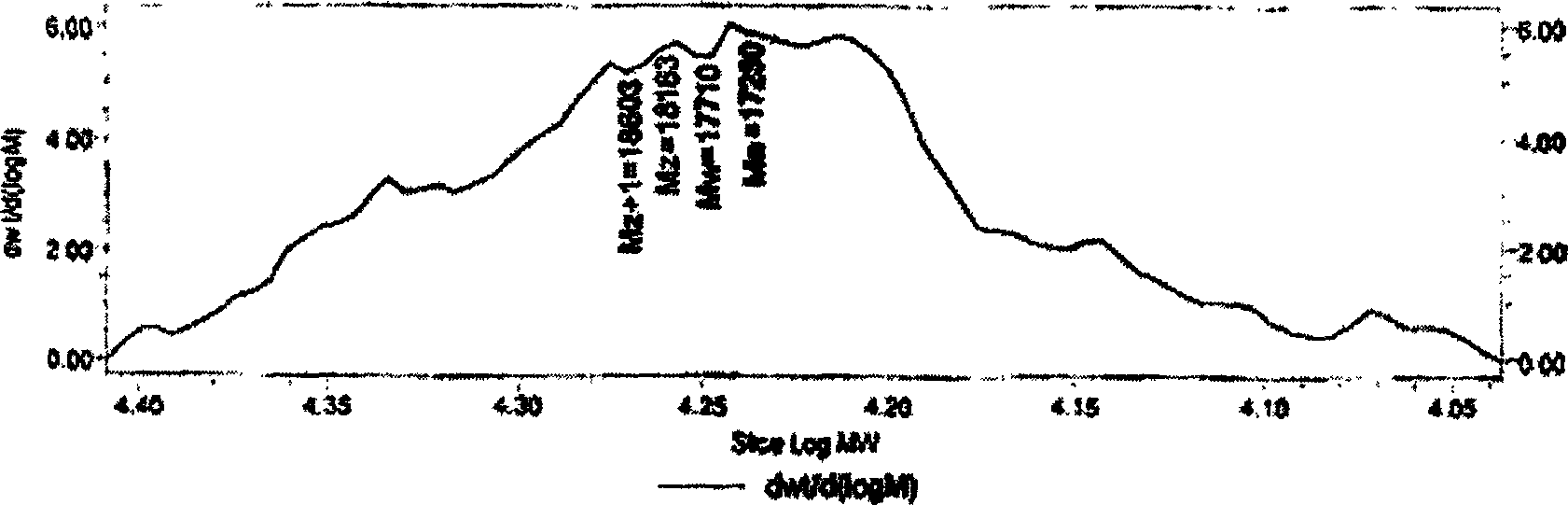

[0037] Embodiment 3: The molecular weight of the cationic oligomeric surfactant PODMAAC-1 synthesized in embodiment 1 has been characterized by gel chromatography, see figure 1 .

[0038] Pump parameters and models: Waters 515 pump

[0039] Host model: Waters 2410 Refractive Index detector

[0040] Solvent: THF

[0041] Column model: μstyragel HR5E 300×4.6mm (inner diameter)

[0042] Temperature: 30°C

[0043] The results of gel chromatography are as follows:

[0044] from figure 1 The weight average molecular weight, number average molecular weight and Z average molecular weight of PODMAAC-1 were obtained. The weight average molecular weight Mw=17710, the number average molecular weight Mn=17250. The weight average molecular weight is quite close to the number average molecular weight (Mw / Mn=1.027), indicating that the molecular weight distribution is narrow and close to monodisperse.

[0045] from figure 1 It can also be calculated that the lowest molecular weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com