Parullel mechanisms for imaginary axis machine tool, measurer, etc.

A simulated experimental device, abrasive jet technology, applied in the field of water jet, can solve difficult, inadaptable, and non-existent problems, and achieve the effect of perfect function and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

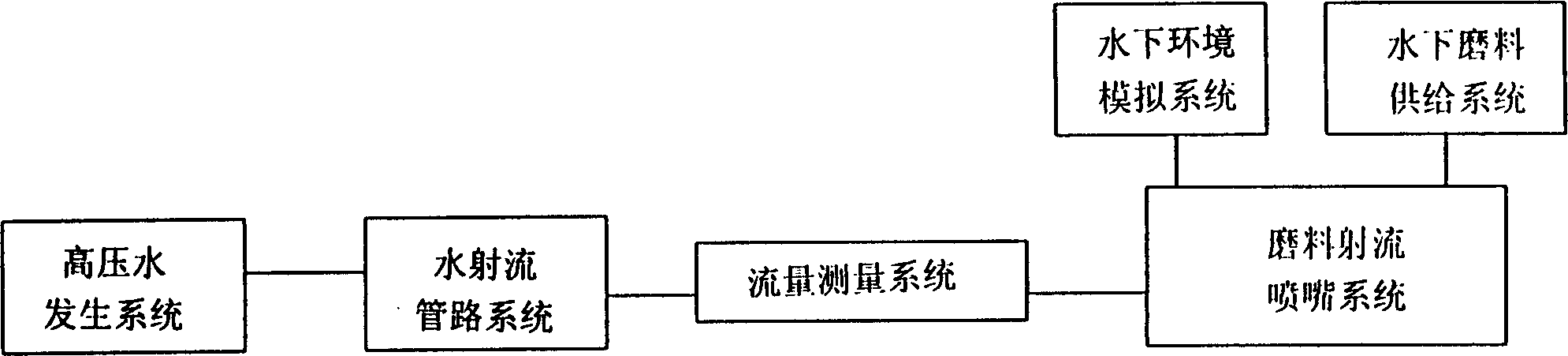

[0019] Depend on figure 1 As shown, it is mainly composed of an underwater environment simulation system and an underwater abrasive jet cutting system. The underwater abrasive jet cutting system includes a high-pressure water generation system, a water jet pipeline system, an underwater environment simulation system, an abrasive jet nozzle system, and an underwater Abrasive supply system, flow testing system.

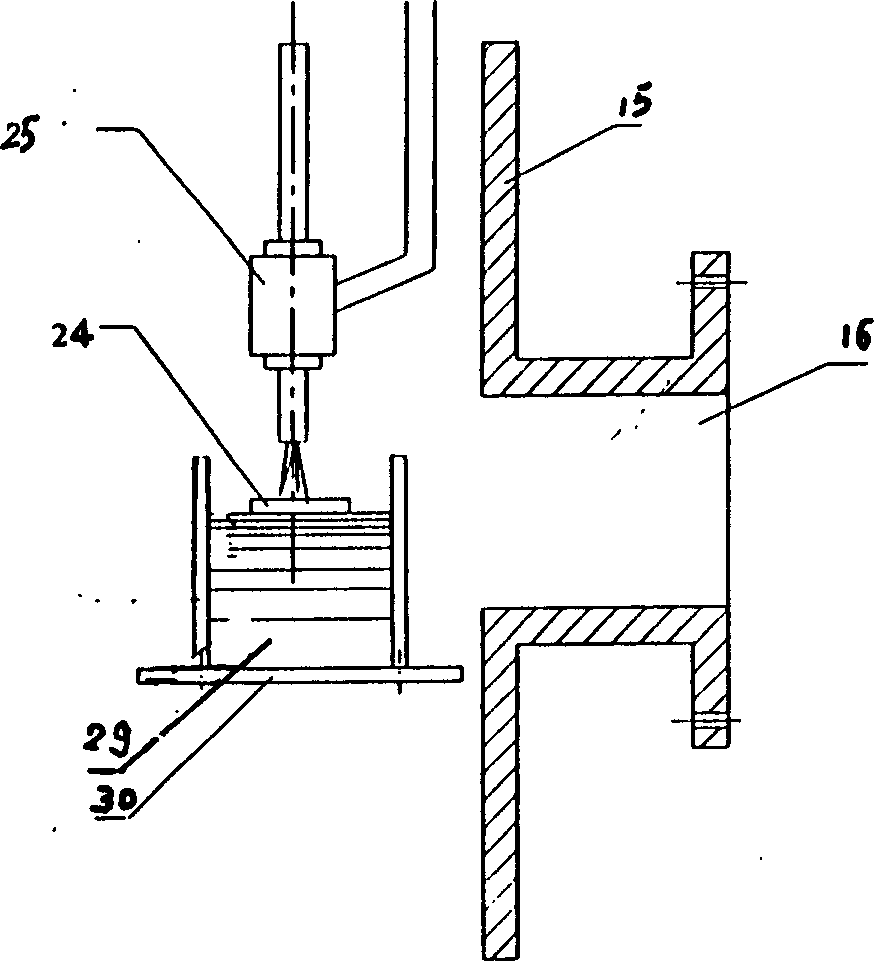

[0020] 1. Underwater environment simulation system, such as figure 2 As shown, it consists of an airtight container 15; an air compressor 4, a precision pressure gauge 8, 18, a water level gauge 5, a needle valve and a muffler 14, a safety valve 6, and a check valve 3 for air in the airtight container are provided. , View mirror hole 20 composition. Airtight container 15 is the main body of the whole system, and its design pressure is 1.6Mpa, belongs to medium pressure container. The maximum pressure is 2.5Mpa, the external dimensions are Φ1224mm×1800mm, and the man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com