Axial sending-off powder type flame gun in supersonic speed using liquid fuel as energy sources

A technology of liquid fuel and axial powder feeding, which is applied in the direction of liquid injection devices, devices for coating liquid on the surface, injection devices, etc. Can not meet the technical requirements, the powder is easy to stick to the inner wall of the gun barrel, etc., to achieve the effect of prolonging the continuous operation time, easy linkage, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

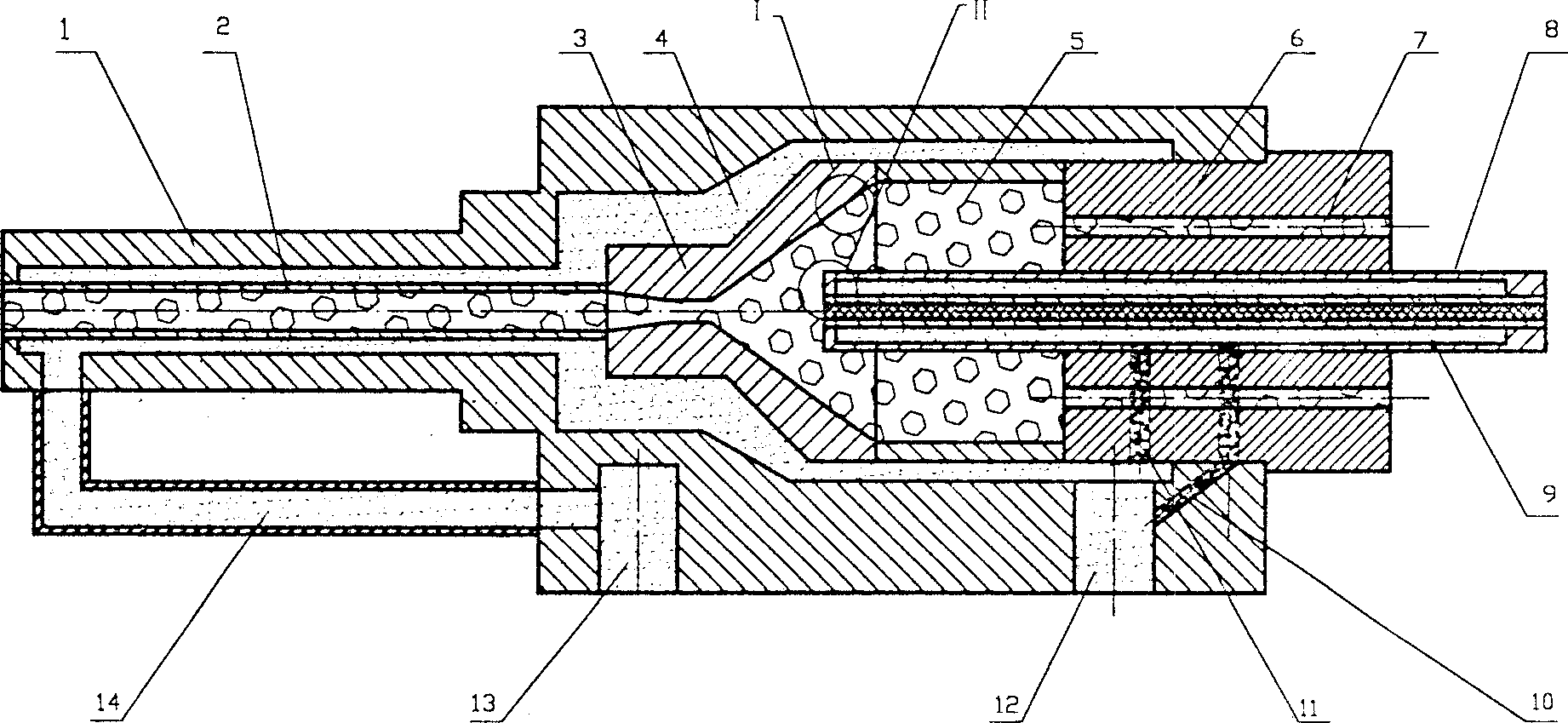

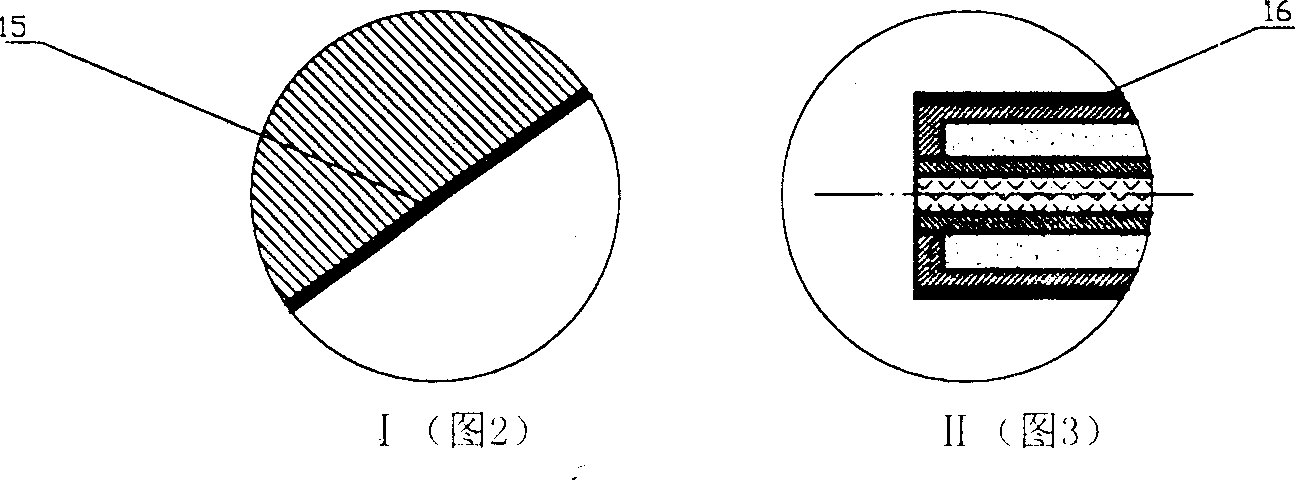

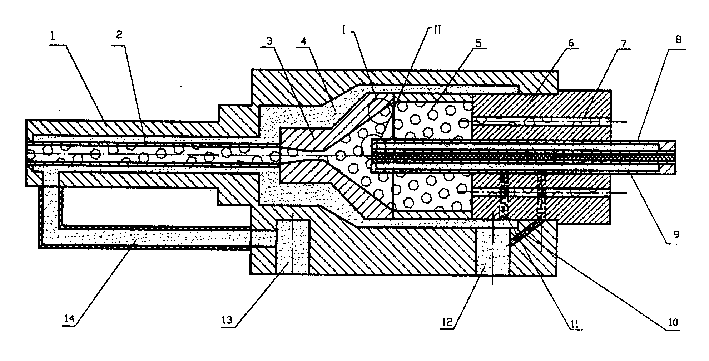

[0012] Depend on figure 1 -3 It can be seen that in the spray gun housing (1), there are gun barrel (2), Laval nozzle (3), combustion chamber (5) and tailstock (6), and are mechanically connected in turn, and the gun barrel (2 ), the Laval nozzle (3), the combustion chamber (5) and the tailstock (6) are formed with the inner surface of the spray gun housing (1) for cooling the gun barrel (2), the Laval nozzle (3), the combustion chamber (5) and the main water cooling passage (4) of the tailstock (6), one end of the passage is connected to the cooling water inlet (13) at the front of the spray gun housing (1) through the connecting pipe (14), and the other end is connected to the spray gun housing (1) The cooling water outlet (12) at the rear is connected. The internal diameter of the Laval nozzle (3) is divided into a necking section and a necking section. The inner wall of the combustion chamber (5) is provided with a heat-resistant coating (15), made of zirconia or alumina,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com