Horizontal epitaxial growth of gallium nitride and its compound semiconductor

A technology of lateral epitaxial growth and gallium nitride, which is applied in the field of lateral epitaxial growth of gallium nitride and its compound semiconductors, can solve the problems of prolonging the epitaxial growth time, increasing the cost, affecting the fabrication of devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0020] Specific examples (see Figure 4 ):

[0021] 1. First, a layer of intrinsic GaN 41 is deposited on a sapphire (0001) substrate 40 by MOCVD, and the thickness of the intrinsic GaN layer is 2 μm.

[0022] 2. Deposit a layer of SiN on the surface of GaN by PECVD x 42 is used as a mask area, and the thickness of the mask area is 0.03 μm.

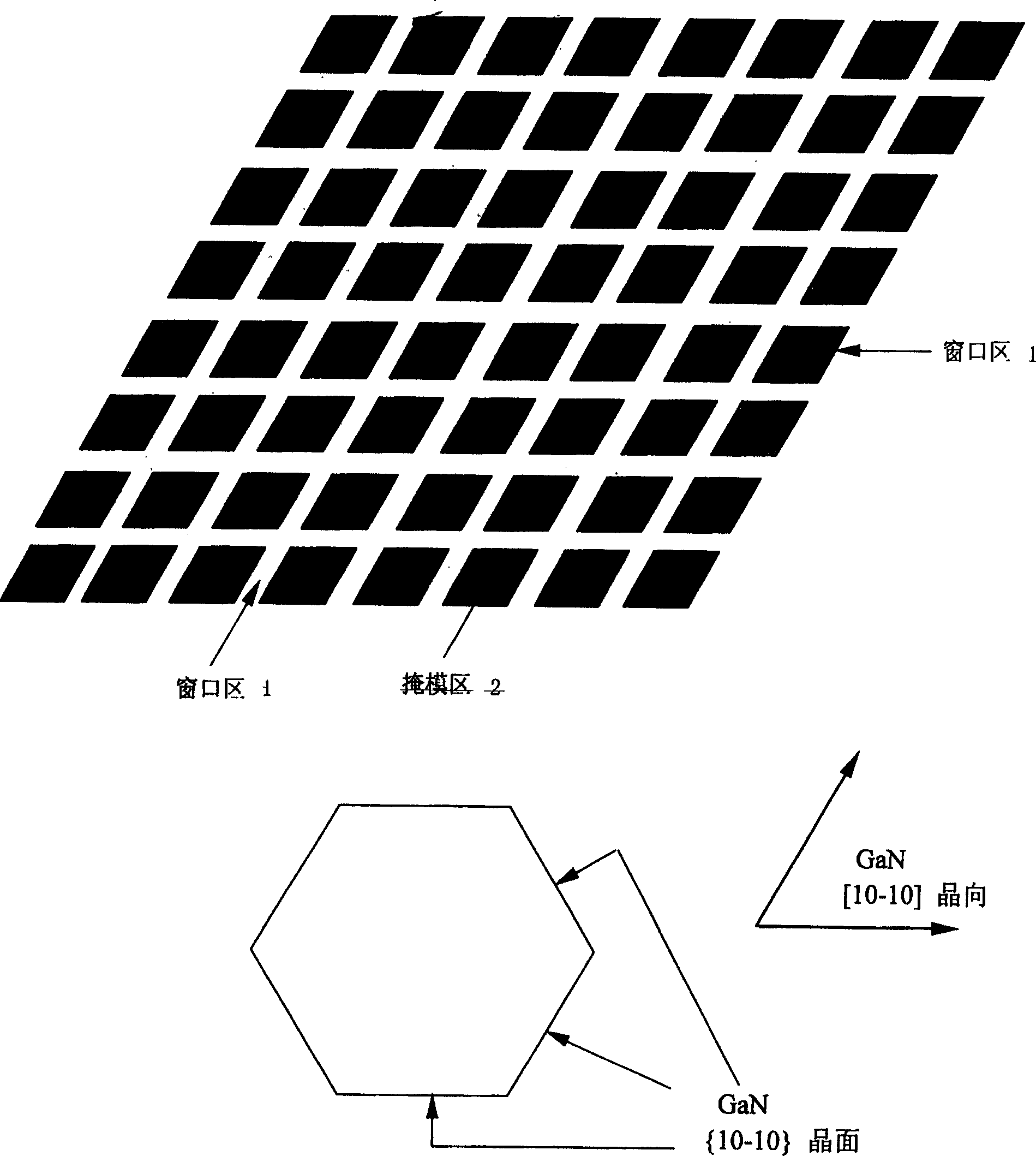

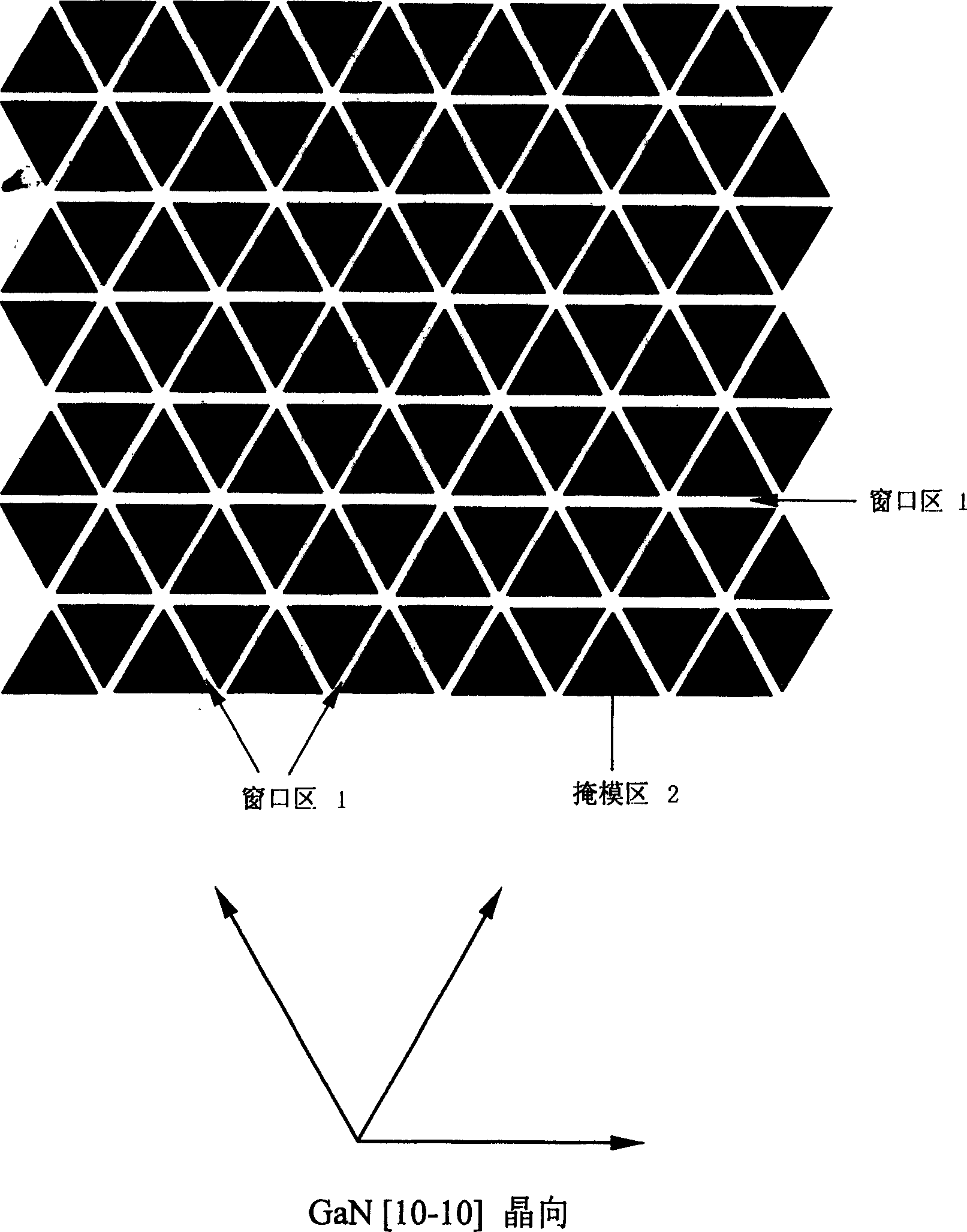

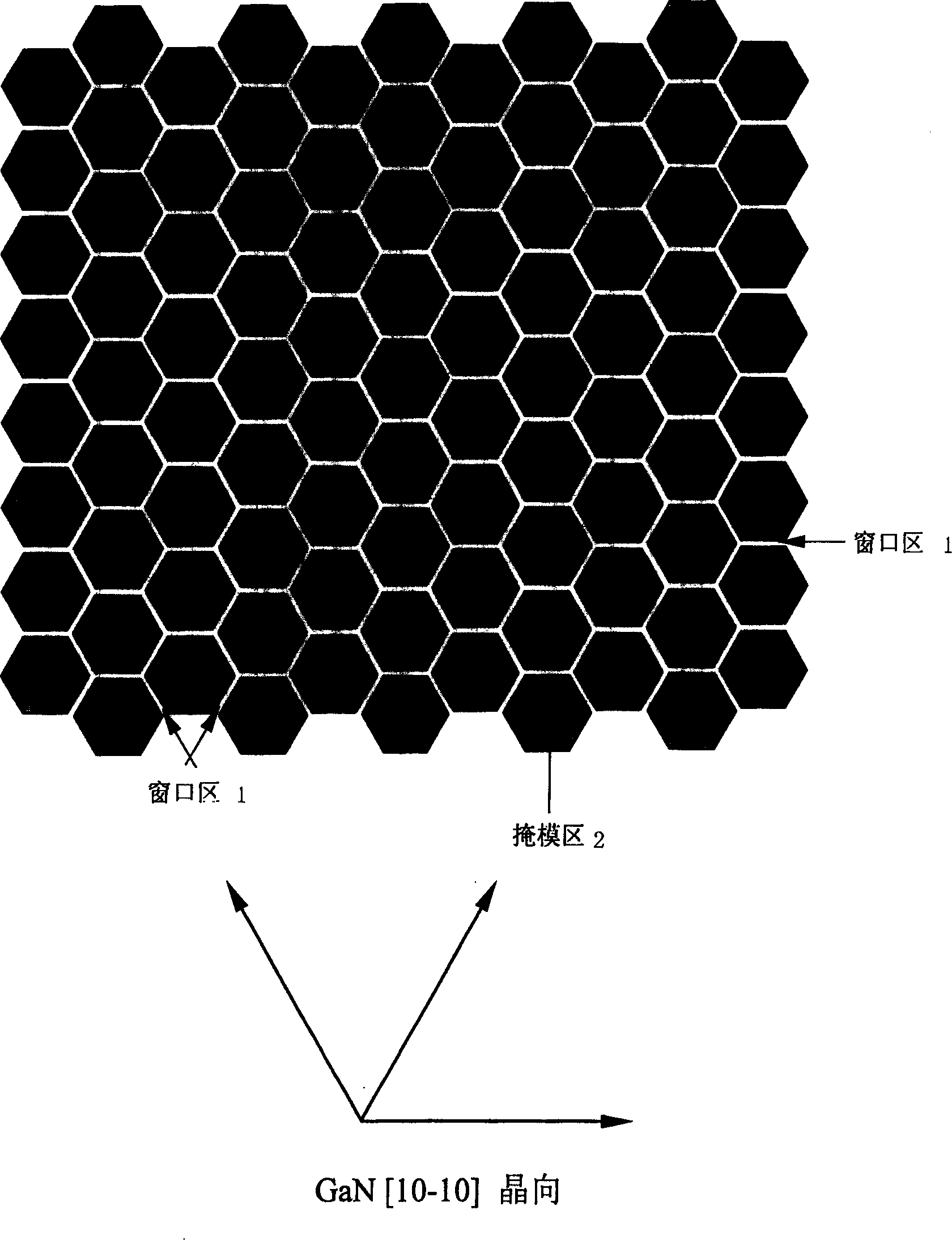

[0023] 3. Using photolithography and wet etching process on SiN x 42 The pattern is engraved on the mask area, and the pattern of the mask area is designed as a rhombic structure with the [10-10] crystal orientation of GaN on the edge of the adjacent window, and the included angle is 60 degrees or 120 degrees. The window area width is 4 μm, and the diamond mask The side length of the mold area is 12 μm.

[0024] 4. Secondary epitaxial growth of GaN and its compound semiconductor 43 is performed on the GaN 41 with a rhombic mask area by MOCVD.

[0025] Depend on Figure 5 It can be seen that the lateral epitaxial GaN surface obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com