Image display device and projector

A film structure and thin film technology, which can be used in decorative arts, patterns and instruments characterized by light projection effects, and can solve the problems of unsatisfactory durability of fluoropolymers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0138] Embodiment 1: the preparation of fluoropolymer

[0139] Add 30 grams of 1,1,2,4,4,5-hexafluoro-3-oxa-5-trifluoromethyl-1,6-heptadiene into a 200ml autoclave made of pressure-resistant glass 【CH 2 =CHCF(CF 3 ) CF 2 OCF=CF 2 ] and 80 grams of perfluorohexane, flushed with nitrogen. 17 mg of bis(heptafluorobutyryl) peroxide was also added as a polymerization initiator. The interior of the experimental apparatus was again flushed with nitrogen. Polymerization was carried out in this vessel at 0°C for 72 hours. As a result of the reaction, 24 g of a fluorine-containing polymer having an alicyclic structure in the main chain (hereinafter referred to as polymer (A-1)) was obtained.

[0140] When the temperature is 30°C, the intrinsic viscosity [η] of the polymer (A-1) in perfluorinated (2-butyltetrahydrofuran) is 0.6dl / g, and the glass transition temperature of the polymer (A-1) is 108 ℃. At room temperature, it is a tough, transparent glassy polymer with a refractive...

Embodiment 2

[0141] Embodiment 2: Preparation of fluoropolymer

[0142] Add 20 g of 1,1,2,4,4,5-hexafluoro-3-oxa-5-trifluoromethyl-1,6-heptadiene into a 100 ml autoclave made of pressure-resistant glass , 7.5 g of perfluoro(2,2-dimethyl-1,3-dioxol) and 80 g of 1H perfluoroethane, flushed with nitrogen. 23 mg of bis(heptafluorobutyryl) peroxide was also added as a polymerization initiator. The interior of the experimental apparatus was again flushed with nitrogen. Polymerization was carried out in this vessel at 10°C for 72 hours. As a result of the reaction, 15 g of a fluorine-containing polymer having an alicyclic structure in the main chain (hereinafter referred to as polymer (A-2)) was obtained.

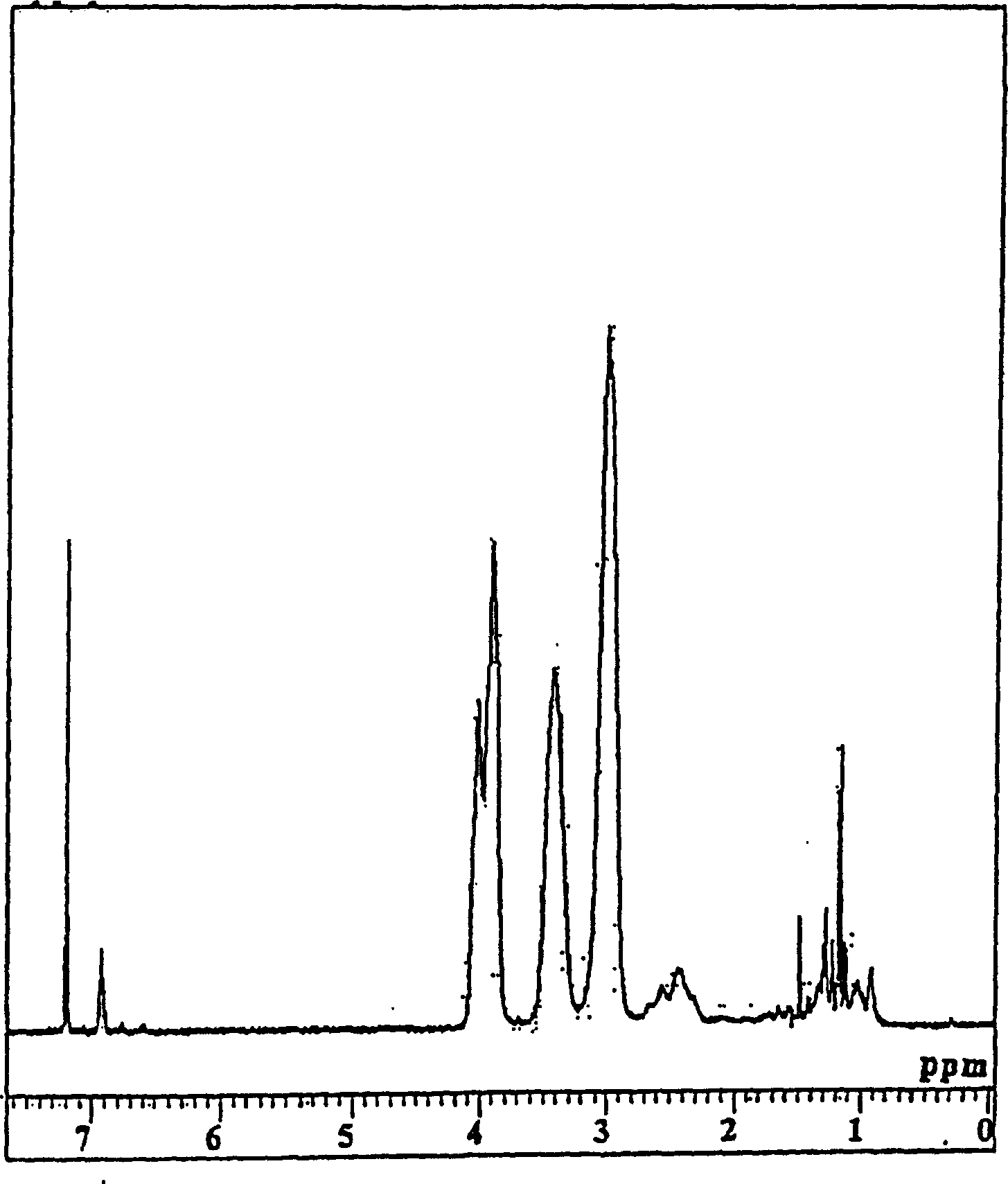

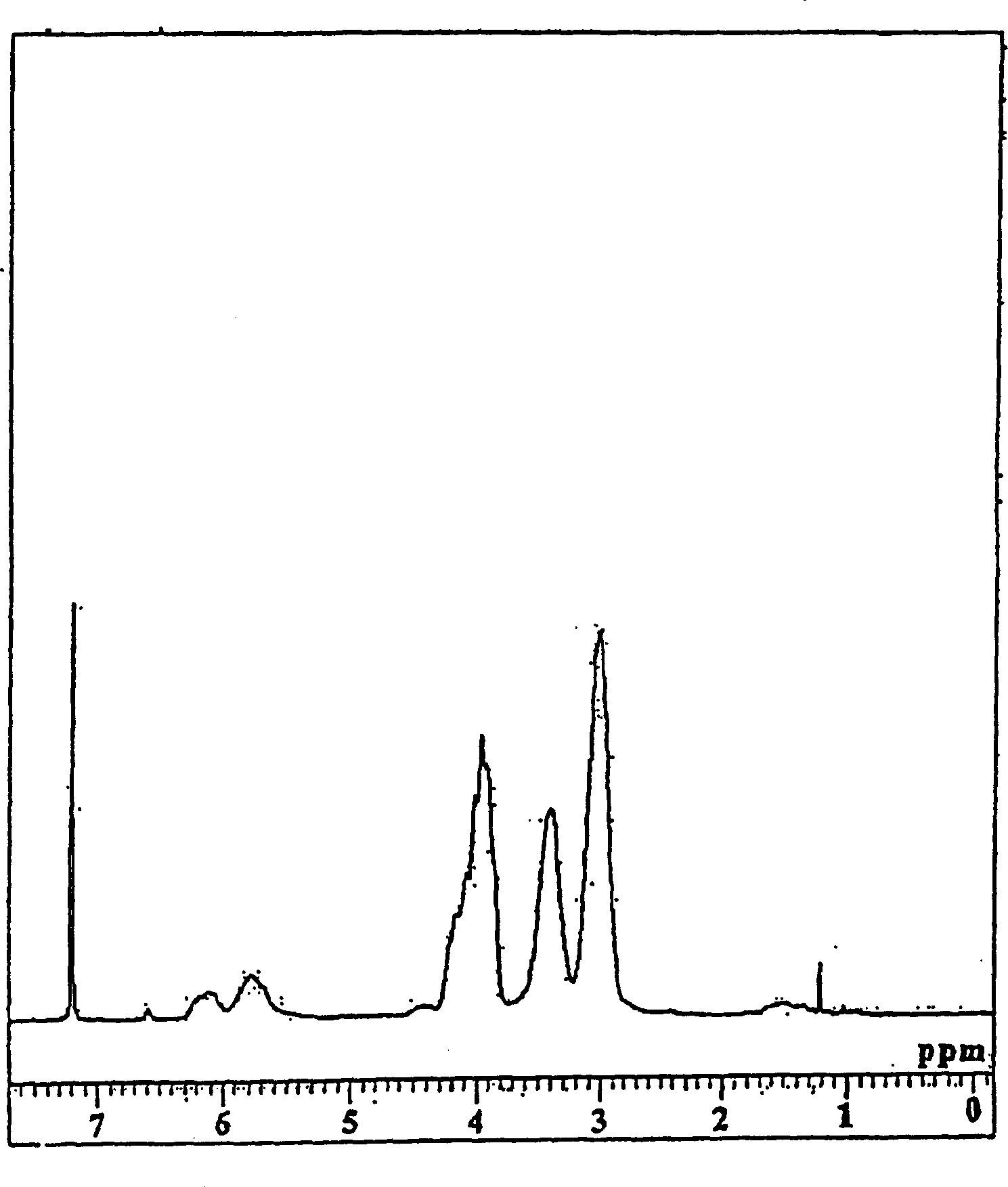

[0143] The intrinsic viscosity [η] of the polymer (A-2) in perfluorinated (2-butyltetrahydrofuran) was 0.62 dl / g at a temperature of 30°C. At room temperature, it is a tough, transparent glassy polymer. After measuring the 1H-NMR spectrum of the polymer (A-2), it was found that no obvious...

Embodiment 3

[0144] Embodiment 3: Preparation of fluoropolymer

[0145] Add 24 grams of 1,1,2,4,4,5-hexafluoro-3-oxa-5-trifluoromethyl-1,6-heptane in a 200ml autoclave made of pressure-resistant glass alkene. Then add a mixture of 29 grams of bis(heptafluorobutyryl) peroxy compound and 70 grams of 1H-perfluoroethane, as the initiator of the polymerization reaction, the inside of the device is flushed with nitrogen, and then 4.6 grams of vinylidene fluoride is added into the gas phase. Next, the polymerization reaction was carried out at 10° C. for 72 hours. As a result, a fluorine-containing compound having an alicyclic structure in the main chain (hereinafter referred to as polymer (A-3)) was obtained.

[0146] The intrinsic viscosity [η] of the polymer (A-3) in perfluorinated (2-butyltetrahydrofuran) at a temperature of 30°C was 0.36 dl / g. At room temperature, it is a tough, transparent glassy polymer. It can be seen from the measurement results of its 1H-NMR spectrum that weak sign...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com