Process for preparing coating of fabric capable of removing harmful substance in air

A fabric and coating technology, which is applied in the field of preparation of inorganic compound coating treated fabrics, can solve problems such as undiscovered nanocomposite fabrics, and achieve the effects of improving anti-aging properties, reducing and controlling aging, and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

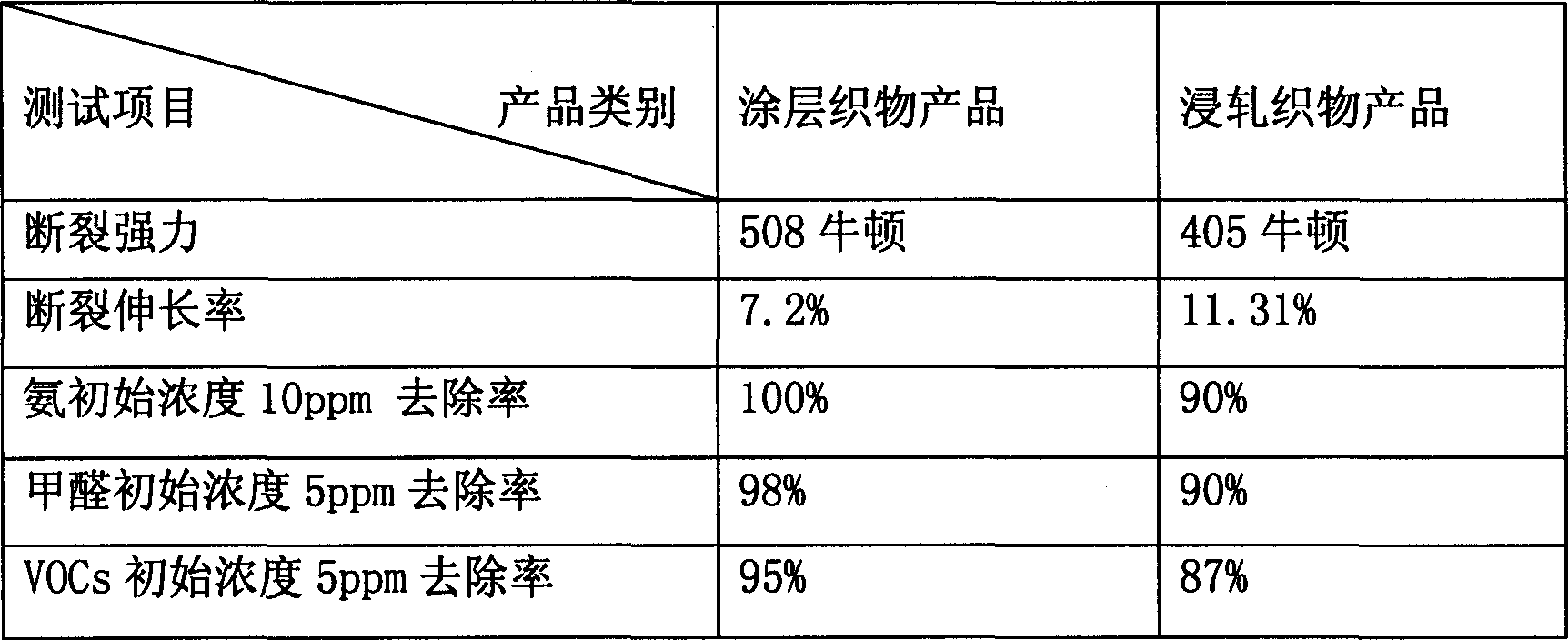

Examples

Embodiment 1

[0026] First, the polyester woven fabric is pretreated, that is, soaked in an aqueous solution of 80°C containing 1 g / L of nonionic surfactant for 20 minutes, then rinsed thoroughly in cold water and dried at room temperature for later use; Use the anti-aging working solution to carry out anti-aging finishing on the pretreated polyester woven fabric. The formula of the anti-aging working solution is: 30 g / L of amino silicone oil emulsion, 10 g / L of zinc nitrate, non-ionic Wetting agent JFC 1 g / L, solvent is water; the loaded polyester woven fabric after anti-aging finishing is coated with primary coating slurry, pre-baked at 100°C for 3 minutes, and then baked at 180°C for 2 minutes , Obtain the polyester woven fabric with active carbon coating on the surface, the primary coating slurry formula is: powder type active carbon 15% (weight percent), polyacrylic acid binder 3% (weight percent), polyacrylic acid thickening Agent 2% (percentage by weight), and the rest is water; Fina...

Embodiment 2

[0036] First, the polypropylene fabric is pretreated, that is, soaked in a 60°C aqueous solution containing 0.5 g / L of nonionic surfactant for 10 minutes, then rinsed thoroughly in cold water and dried at room temperature for later use; The anti-aging working liquid is used for anti-aging finishing of the pretreated polypropylene fabric. The formula of the anti-aging working liquid is: 20 g / L of fluorine-containing polymer emulsion, 15 g / L of magnesium chloride, and non-ionic wetting agent JFC in each liter of working liquid. 1.5 g / L, the solvent is water; the loaded polypropylene fabric after anti-aging finishing is coated with the primary coating slurry, pre-baked at 80°C for 2 minutes, and then baked at 150°C for 1 minute to obtain a surface attached The fabric of activated carbon coating is arranged, and the primary coating slurry formula is: powder type activated carbon 5% (weight percent), polyacrylic acid binder 2% (weight percent), polyacrylic acid thickener 1% (weight ...

Embodiment 3

[0046] First, the cotton woven fabric is pretreated, that is, soaked in a 70°C aqueous solution containing 2 g / l of nonionic surfactant for 30 minutes, then rinsed thoroughly in cold water and dried at room temperature for later use; Use the anti-aging working solution to carry out anti-aging finishing on the pretreated cotton woven fabric. The formula of the anti-aging working solution is: 40 grams / liter of amino silicone oil emulsion, 20 grams / liter of magnesium nitrate in each liter of working solution, non-ionic moisturizing The agent JFC is 2 grams per liter, and the solvent is water; the loaded cotton woven fabric after anti-aging finishing is coated with the primary coating slurry, pre-baked at 90°C for 5 minutes, and then baked at 160°C for 3 minutes to obtain Cotton woven fabric with activated carbon coating attached to the surface, the primary coating slurry formula is: powder type activated carbon 25% (weight percent), polyacrylic acid adhesive 5% (weight percent), p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com