Growth apparatus for large-areaed crystal by temperature gradient technique and crystal growth method thereof

A growth device and large-area technology, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of inability to grow crystals, crystal cracking, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

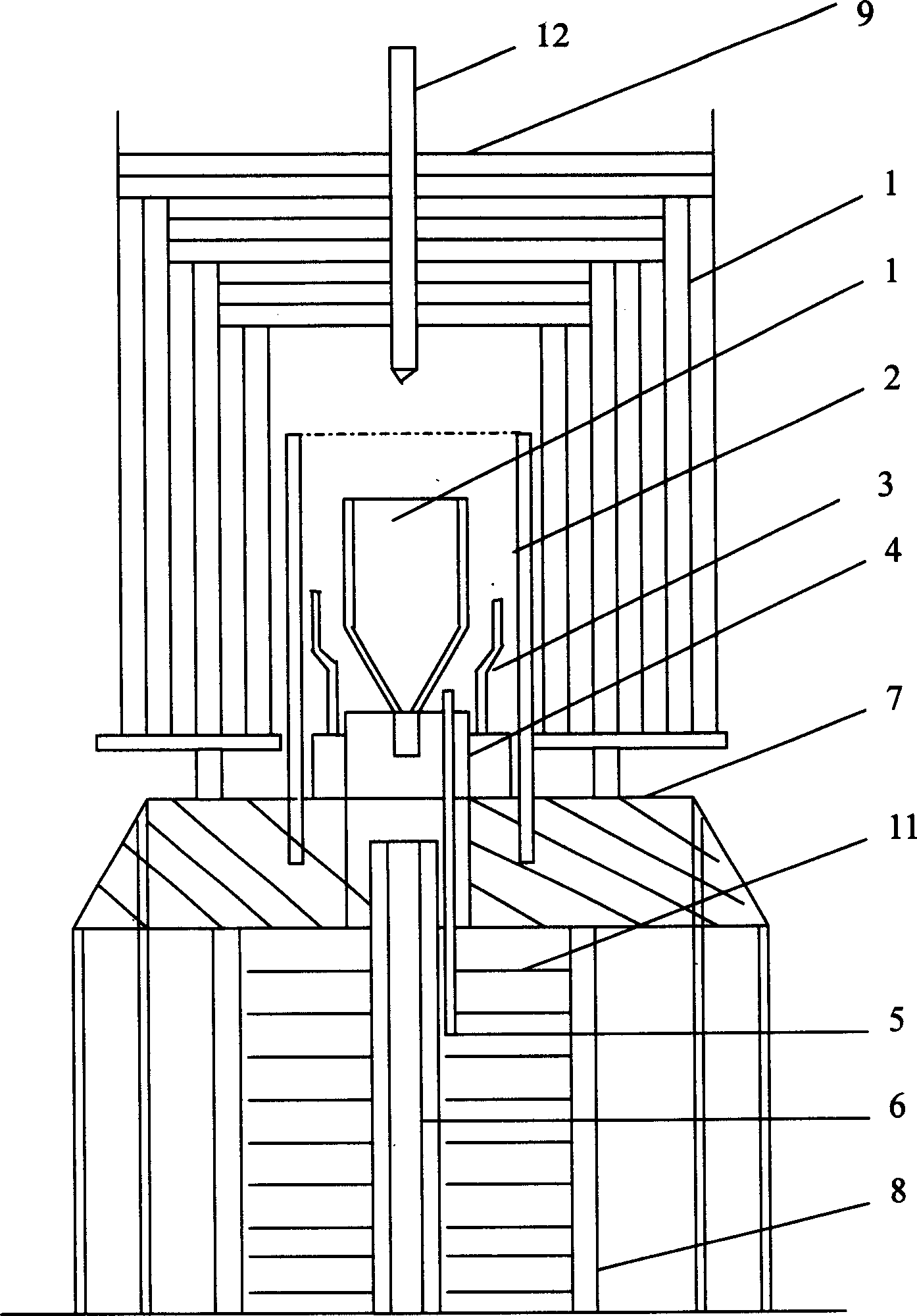

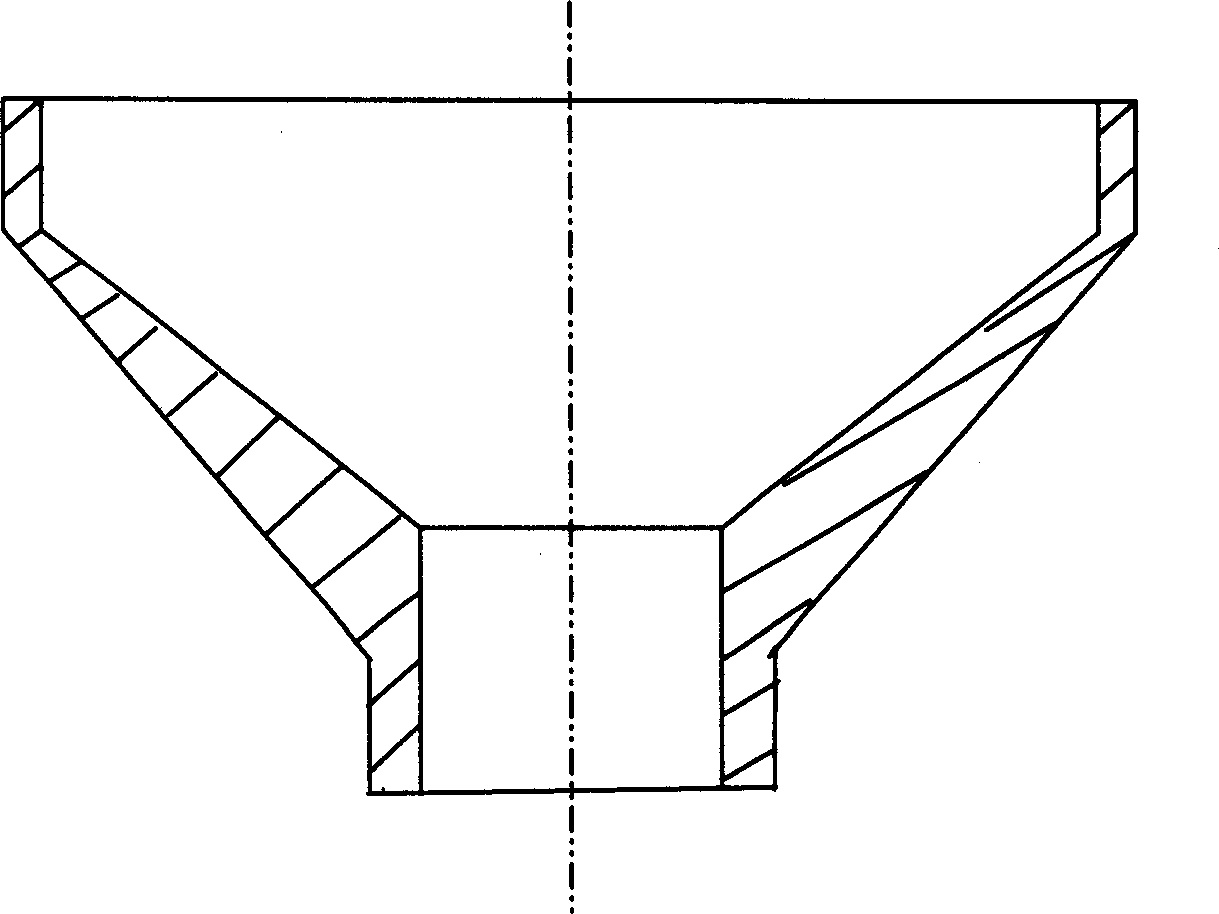

[0035] Carry out calcium fluoride crystal (CaF 2 ) growth

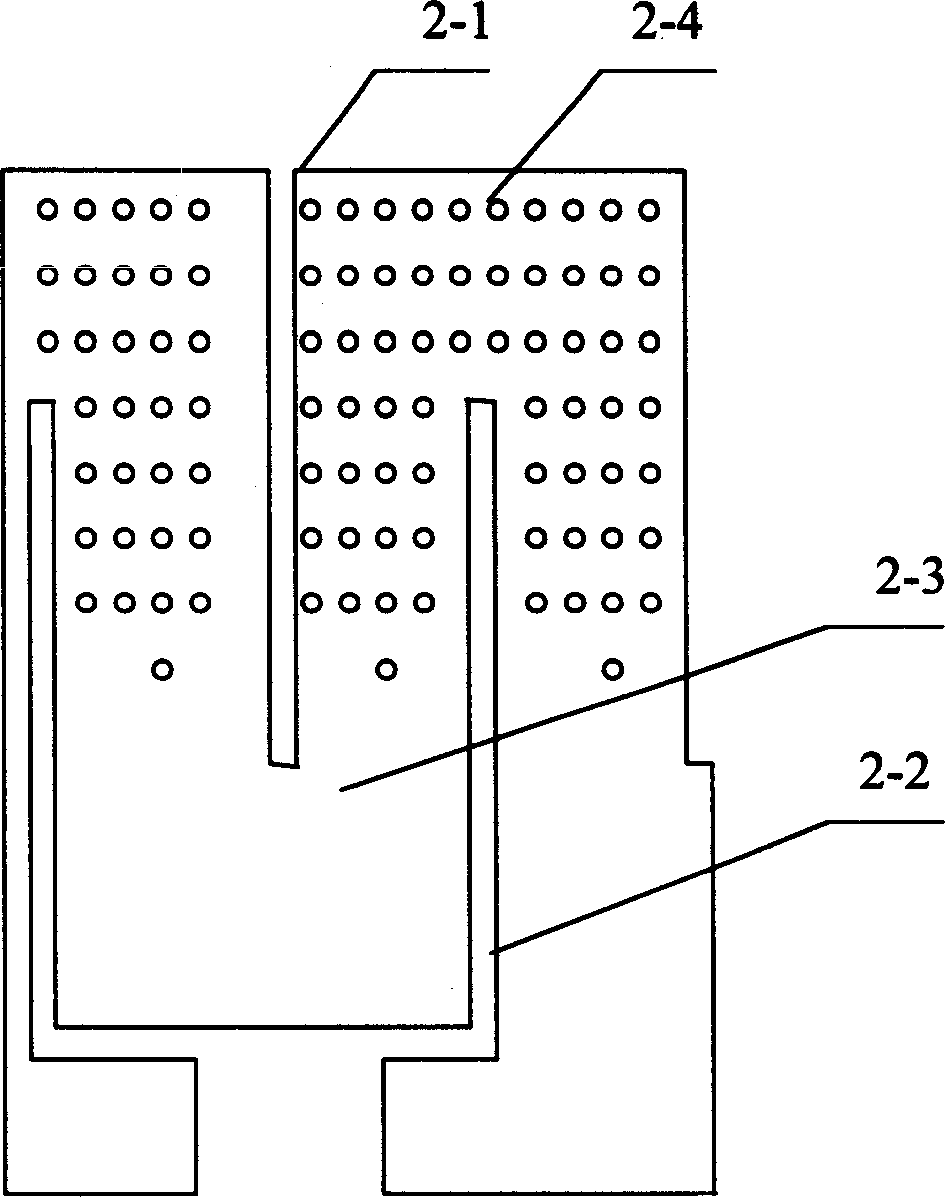

[0036] Graphite (C) crucible 1 has a size of Ф220×250 mm, and is a conical crucible with a seed crystal groove in the center of the bottom. The graphite heating element 2 is barrel-shaped, and the inner layer of the insulation screen is lined with a molybdenum cylinder of tungsten sheets. [111] Oriented seeds. 10kg CaF 2 Powder and 1kg PbF 2 After the powder was mixed in the mixer for 24 hours, 1% of PbF 2 The powder is used as a deoxidation scavenger, with 2t / cm 2 The isostatic pressing block, or CaF 2 The crystal block material is directly loaded into the crucible 1, sealed with a graphite crucible cover, placed in a temperature gradient furnace, and heated up to 800°C (thermocouple 5) while vacuuming, and filled with a high-purity argon protective atmosphere to 1 atmosphere. By adjusting the main heating element and the auxiliary heating element, the temperature is independently controlled respectively, and ...

Embodiment 2

[0037] Embodiment 2: carry out sapphire crystal (Al 2 o 3 ) growth

[0038] The crucible 1 made of molybdenum (Mo) has a size of Ф160×180 mm, and is a conical crucible with a seed crystal groove in the center of the bottom. The graphite heating element 2 is barrel-shaped, and the inner layer of the insulation screen is lined with a molybdenum cylinder of tungsten sheets. [0001] Orientation Seed. Sapphire (Al 2 o 3 ) powder with 2t / cm 2 The isostatic pressure forging block, or sapphire (Al 2 o 3 ) crystal block material, directly put into the crucible 1, place in the temperature gradient furnace, heat up to 1000°C (thermocouple 5) while vacuuming, fill the high-purity argon protective atmosphere to 1 atmosphere, adjust the main heating element and The temperature of the auxiliary heating element is independently controlled. After forming a stable and suitable thermal field, two sets of intelligent temperature controllers will automatically complete the whole process of ...

Embodiment 3

[0039] Embodiment 3: Carry out garnet crystal (Y 3 al 5 o 12 ) growth

[0040] The crucible 1 made of molybdenum (Mo) has a size of Ф160×180 mm, and is a conical crucible with a seed crystal groove in the center of the bottom. The graphite heating element 2 is barrel-shaped, and the inner layer of the insulation screen is lined with a molybdenum cylinder of tungsten sheets. [111] Oriented seeds. The 5:3 stoichiometric ratio of Al 2 o 3 and Y 2 o 3 After the powder is mixed in the mixer for 24 hours, use 2t / cm 2 isostatic pressure forging into blocks, put it directly into the crucible 1, place it in a temperature gradient furnace, raise the temperature to 1000°C (thermocouple 5) while vacuuming, fill the high-purity argon protective atmosphere to 1 atmosphere, and adjust the main The temperature of the heating element and the auxiliary heating element are independently controlled. After forming a stable and suitable thermal field, two sets of intelligent temperature co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com