Method for mfg. semiconductor device

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven heating temperature, high price, difficult heat treatment temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

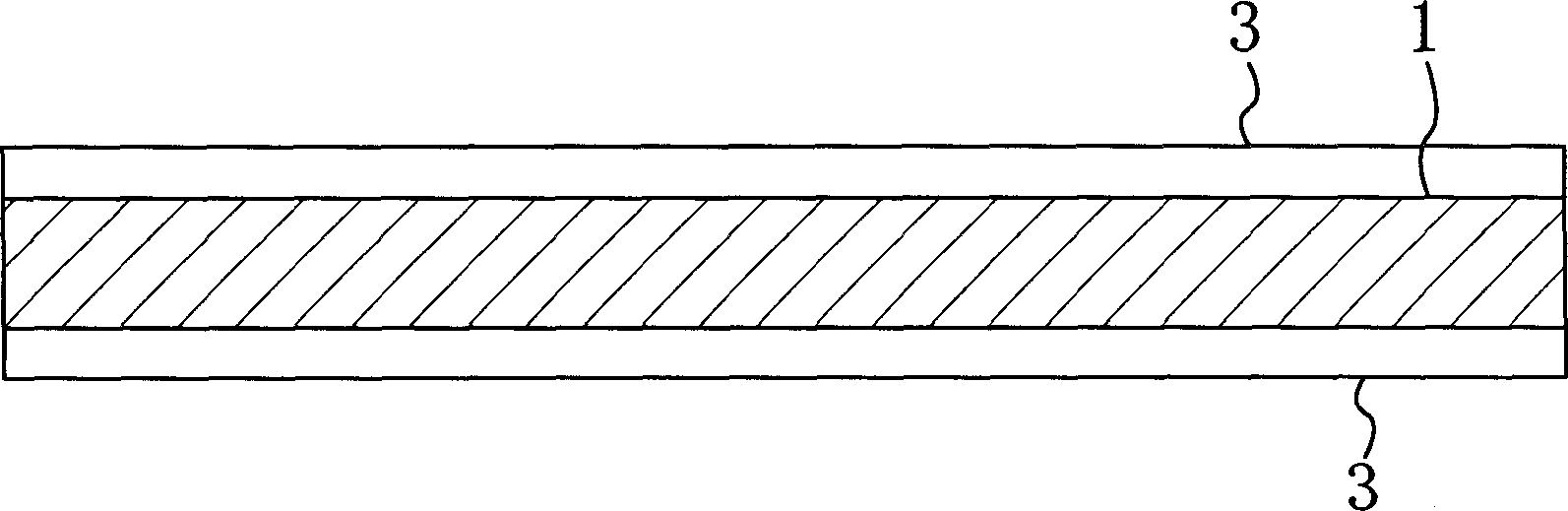

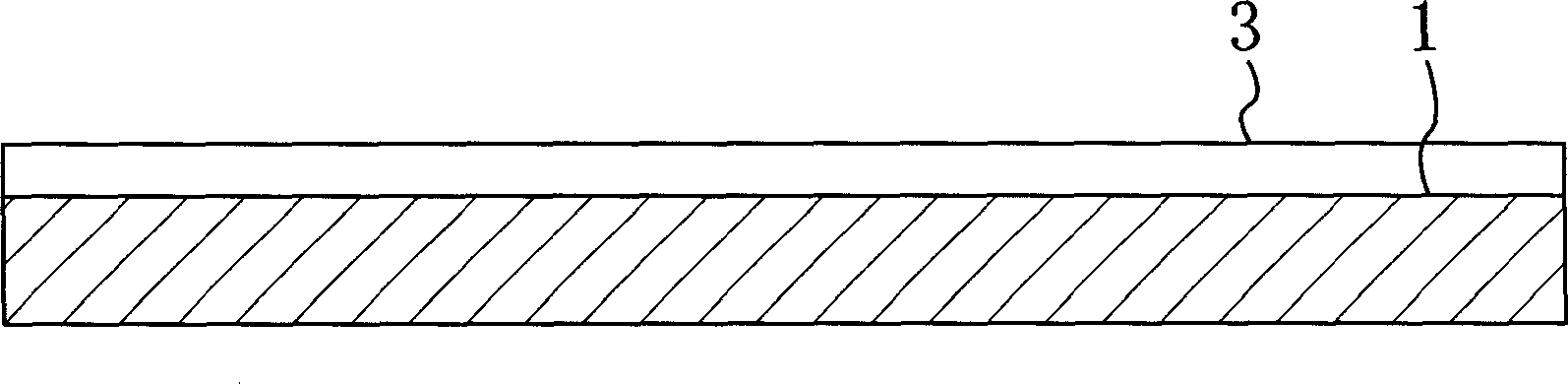

[0053] Figure 1(a) to Figure 1(c) , is a partial sectional view showing the semiconductor device manufacturing method according to the first embodiment of the present invention.

[0054] In the process shown in FIG. 1(a), first, a silicon semiconductor substrate 1 is prepared. Next, silicon oxide films are formed on the upper and lower surfaces of the substrate 1 by vapor phase deposition (CVD) or the like.

[0055] Next, in the process shown in FIG. 1(b), silicon oxide film 3 on the lower surface (back surface) of semiconductor substrate 1 is removed by wet etching.

[0056] Next, in the process shown in Figure 1(c), the substrate is placed on POCl 3 In a gas environment, it is heated to 850° C., and phosphorus (P) is implanted into the lower part of the semiconductor substrate 1 by means of heat conduction. As a result, the lower portion of the semiconductor substrate 1 is formed with a thickness of more than 3 μm and an average concentration of 3×10 18 cm -3 The above...

no. 2 approach

[0085] In the method of manufacturing a semiconductor device according to the second embodiment of the present invention, the method of forming the free carrier absorbing layer is different from that of the first embodiment. Below, it will be explained with reference to the figure.

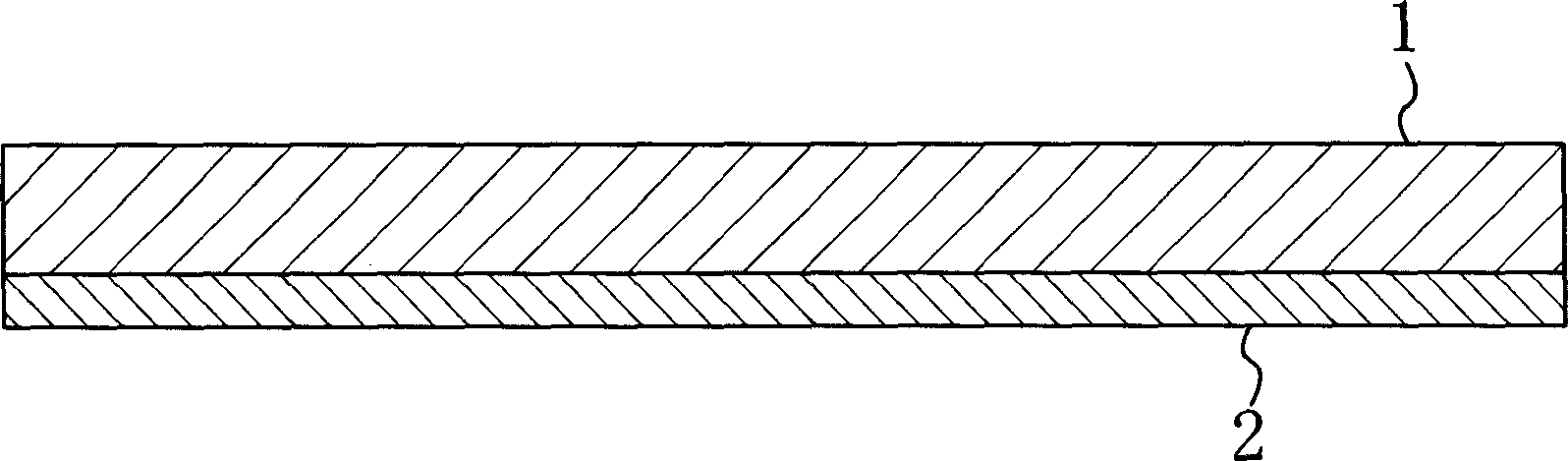

[0086] 5(a) and 5(b) are partial cross-sectional views showing a semiconductor device manufacturing method according to a second embodiment of the present invention.

[0087] First, in the process shown in FIG. 5( a ), N-type impurities are implanted into a region deeper than 3 μm from the upper surface of semiconductor substrate 1 by ion implantation. Thus, an average impurity concentration of 3×10 18 cm -3 Above, the free carrier absorbing layer 2 having a thickness of 3 μm or more. Thereafter, the semiconductor device is fabricated on the semiconductor substrate 1 .

[0088] Also, rapid thermal (RTP) processing is performed in the manufacturing process of the semiconductor device. In this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com