Prepn of super-paramagnetic polymer microsphere

A superparamagnetic and polymer technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as insufficient iron content, insufficient magnetism, and serious agglomeration, and achieve high product purity, Size-controllable, easily dispersed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

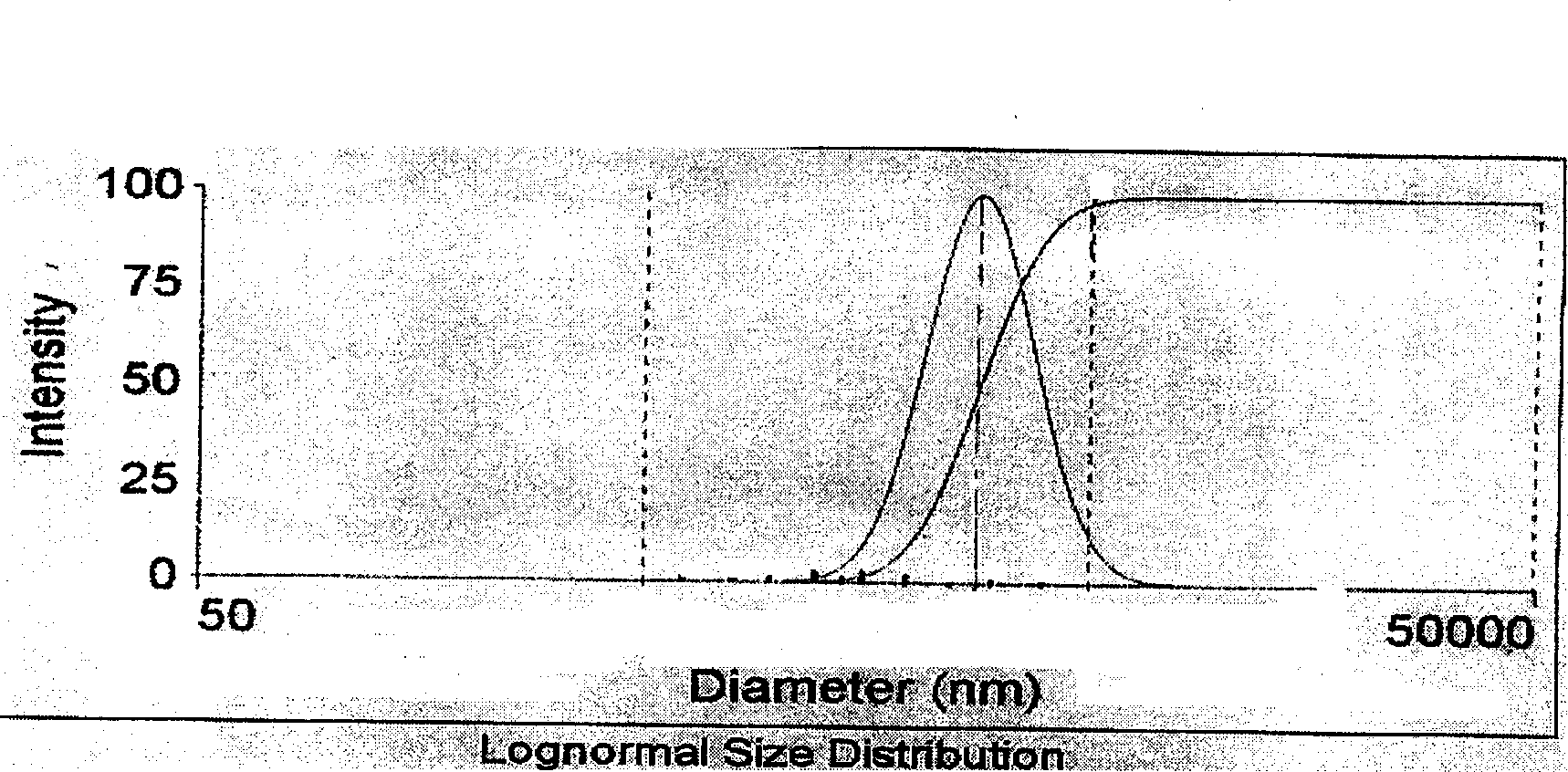

[0036] Example 1: Preparation of Coated Superparamagnetic Nano Ferric Oxide Particles by Improved Co-precipitation Method

[0037] Will weigh FeCl 2 1.7169 g of solid sample, FeCl 3 4.6465 grams and 0.9217 grams of aluminum nitrate are mixed liquid 58ml, 200ml are put into there-necked flask successively, then continue vacuuming and feed nitrogen, make reaction solution under the protection of nitrogen. The temperature of the prepared water bath is set to 40°C, the stirring speed is 1500r / min, the concentration of the ammonia solution is 1mol / l, and the amount of ammonia water added dropwise is 100ml in the whole process. Blend at original speed. Add the oleic acid of 8ml, continue reaction 45 minutes under original stirring speed. Take the sample out and wash it thoroughly with a large amount of absolute ethanol and water.

example 2

[0038] Example 2: Preparation of Coated Superparamagnetic Nano Ferric Oxide Particles by Improved Co-precipitation Method

[0039] Will weigh FeCl 2 1.5169 g of solid sample, FeCl 3 4.0465 grams and magnesium nitrate 0.5217 grams of mixed liquid 50ml, 200ml are put into there-necked flask successively, then continue to vacuumize and feed nitrogen, make reaction solution under the protection of nitrogen. The temperature of the prepared water bath is set to 35°C, the stirring speed is 1500r / min, the concentration of the ammonia solution is 1mol / l, and the amount of ammonia water added dropwise is 100ml in the whole process. Blend at original speed. The sodium oleate of 6ml was added, and the reaction was continued for 30 minutes at the original stirring speed. Take the sample out and wash it thoroughly with a large amount of absolute ethanol and water.

example 3

[0040] Example 3: Preparation of coated superparamagnetic polymer microspheres by microsuspension polymerization

[0041] Disperse the surface-modified magnetic particles in styrene to form a magnetic fluid, take about 8ml, mix with 4ml divinylbenzene, 0.4g benzoyl peroxide and ultrasonically disperse for about 1 hour, at the same time add 0.25g emulsifier Sodium lauryl sulfate and co-emulsifier cetyl alcohol 0.2g were sequentially added to 80ml water at 60°C. After stirring for a certain period of time, 0.015g sodium hydroxide was added to adjust the pH value between 9 and 1, and the dispersed magnetic The fluid is added dropwise into the reaction bottle, fully emulsified for a certain period of time to prepare a microemulsion, reacted for 40 minutes, then dropwise added a mixed solution of 4ml of methacrylic acid and 10ml of an aqueous solution containing 0.1g of potassium persulfate, and then polymerized for 3 hours. Ethanol, methanol, chloroform, water, etc. can be fully w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com