Dispersion for preventing electrification and antistatic film, and image display device

A technology for an image display device and an anti-charge film, which is applied to image/graphic display tubes, identification devices, circuits, etc., can solve the problems of small film thickness dependence, inability to use the anti-charge film, lack of reliability, etc., and achieve good display. Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] First, antistatic dispersion A (hereinafter referred to as dispersion A) having the following composition was prepared

[0066] Antimony pentoxide (pyrochlore crystal form) (particle size 20nm)……1.0%

[0067] Ethanol ……99.0%

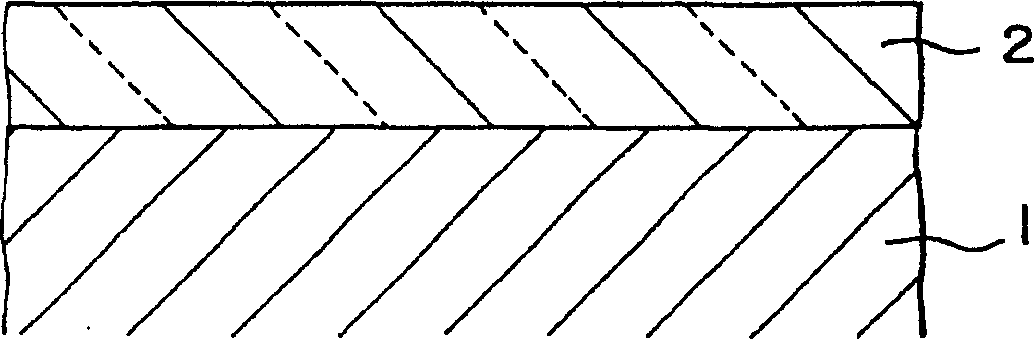

[0068] The dispersion A is applied to the inner wall surface of the tube neck (outer diameter 22.5 mm) of a 15-inch color cathode ray tube with brush hairs along the length of about 15 mm in the tube axis direction, and then heated at a temperature of about 450 ° C and heated by After firing, an antistatic film with a film thickness of 300 nm was formed.

[0069] Also, as Comparative Example 1, the antistatic dispersion B (hereinafter referred to as dispersion B) was prepared with the following composition, and the antistatic film (thickness: 100 nm) was prepared in the same manner as in Example 1 using this dispersion B. Formed on the inner wall surface of the neck of the color cathode ray tube.

[0070] ATO (particle size 10nm) ... 1.0%

[0...

Embodiment 2

[0073] By means of sol-gel method, SiO 2 The thus-constituted coating layer (thickness: 1 nm) was formed on the surface of the ATO microparticles with a particle diameter of 50 nm to produce composite microparticles C (hereinafter, referred to as microparticles C). The fixed resistance of the small C obtained by measuring the particles is 10 8 Ω·cm.

[0074] Hereinafter, after preparing the antistatic dispersion D (hereinafter referred to as dispersion D) with the following composition using the microparticles C, the antistatic film (thickness: 150 nm) was formed in the same manner as in Example 1 using the dispersion. Formed on the inner wall surface of the neck of the color cathode ray tube.

[0075] Microparticle C ... 1.0%

[0076] Ethanol ……99.0%

[0077] Next, for the color cathode ray tubes having the antistatic coatings obtained in Examples 1, 2 and Comparative Example 1, the convergence drift characteristics (variation), the presence or absence of sparks in the tu...

Embodiment 3

[0081] The dispersion A prepared in Example 1 was applied to the entire surface of the spacer member made of low-alkali glass for FED by brush coating, and then heated at a temperature of about 450°C to form a film thickness 500nm antistatic film.

[0082] Then, using this spacer, an FED is assembled by a known method. That is, the rear plate provided with the plurality of electric field emission type electron sources and the phosphor screen arranged in a predetermined pattern to form the phosphor layer are arranged facing each other through the spacer having the above-mentioned antistatic film, and the side plate etc. are bonded at the peripheral portion. By means of packaging, to make FED.

[0083] Also, as Comparative Example 2, using the above-described dispersion liquid B, an antistatic film was formed on the surface of the spacer member in the same manner as in Example 3, and an FED was produced using this film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com