Surface electrospark discharge method with graphite electrode to reinforce titanium alloy material

A graphite electrode and strengthening treatment technology, applied in the field of surface strengthening treatment, can solve the problems of low current utilization rate and production efficiency, unstable processing parameters, affecting the use effect, etc., to achieve convenient operation, dense surface strengthening points, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

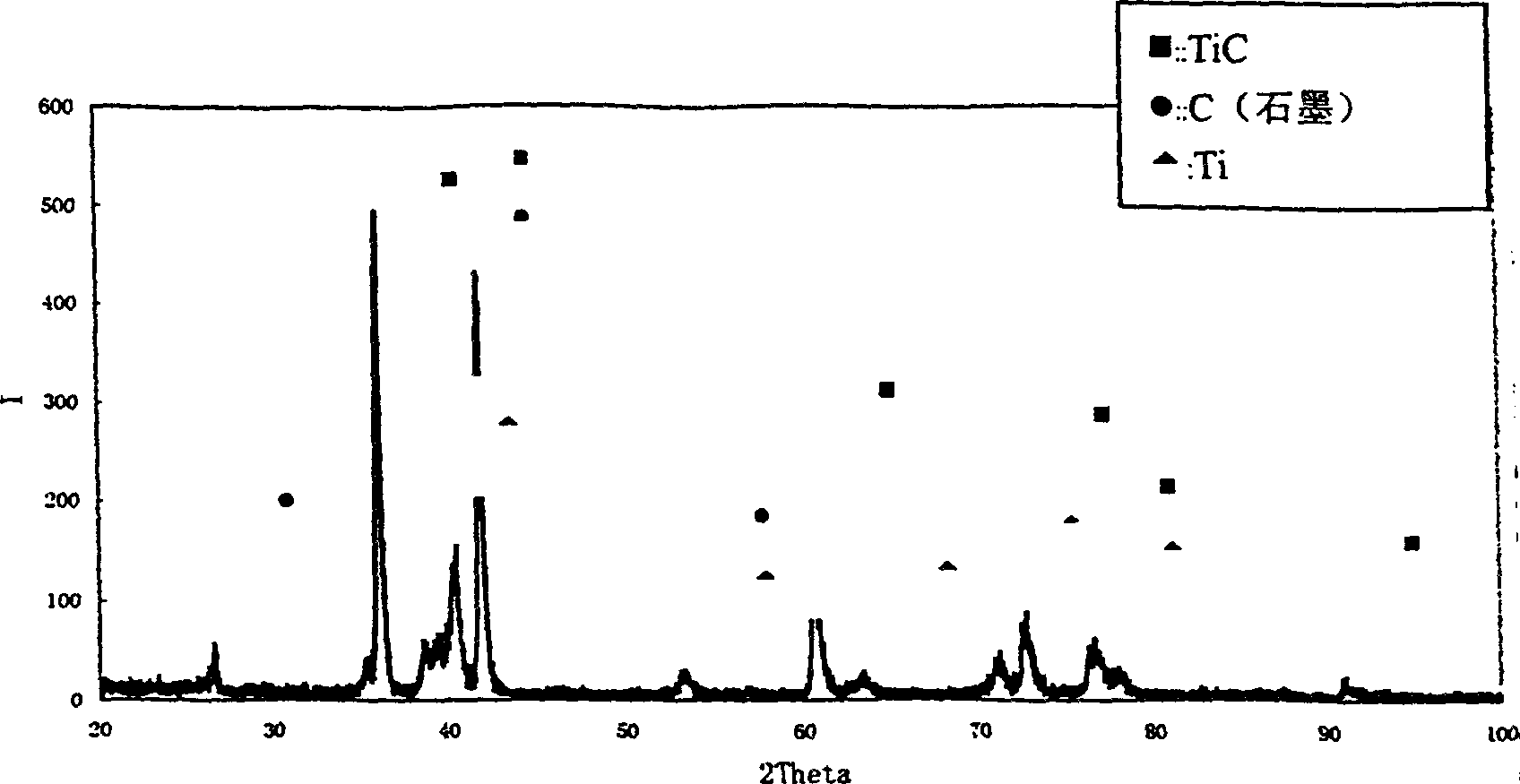

[0015] The method of the present invention adopts a kind of electric spark intensifier with small discharge energy, high discharge efficiency, controllable pulse discharge function, automatic control of the whole machine by programmable sequencer PLC, and the surface roughness is not greater than Ra3.2, The workpiece with a smooth, dry, and dirt-free surface is connected to the negative electrode of the pulse current, and the graphite electrode is connected to the positive electrode of the pulse current to form a discharge circuit for electric spark discharge, so that graphite and Ti undergo a chemical reaction, resulting in TiC strengthening phase, graphite electrode in the method: the degree of graphitization is greater than 50%, the hardness is less than HS30, the resistivity is 10-25μΩm, and does not contain other metal impurities. The size and shape of the electrode can ensure convenient and reliable coating; the electromechanical parameters are: processing voltage 50-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of graphitization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com