High-strength and high-conductivity RE-Cu alloy and its production process

A manufacturing method and technology of rare earth copper, applied in the field of copper-based alloys and its manufacturing, can solve unrelated problems, and achieve the effect of low raw material cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

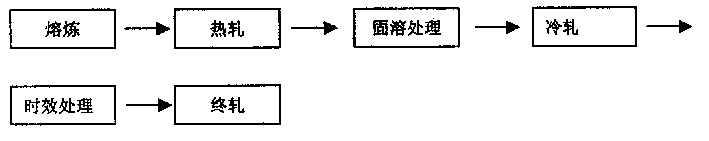

Method used

Image

Examples

Embodiment 1

[0022] CuCrZrZnLa alloy is smelted with the following raw materials: electrolytic copper, copper-10% chromium master alloy, copper-10% zirconium master alloy, copper-5% lanthanum master alloy, copper-30% zinc master alloy. The composition of the alloy is shown in Example 1 of Table 1.

[0023] 1. Melting: Melting with melting equipment used in the industry. The order of alloy addition is: first add electrolytic copper, copper-chromium master alloy, smelt for 20 minutes after melting, add copper-lanthanum master alloy for 3 minutes, and finally add copper-zinc master alloy and copper-zirconium master alloy for 3 minutes, then Cast it.

[0024] 2. Hot rolling: After the ingot is peeled, it is heated to 900°C, kept for 2 hours, and subjected to 70% deformation treatment.

[0025] 3. Solution treatment: Heat the deformed alloy to 970°C, keep it for 30 minutes, and quench it into water;

[0026] 4. Cold rolling: the alloy is deformed by 85%;

[0027] 5. Aging treatment: keep the alloy ...

Embodiment 2

[0031] CuCrZrZnLaFeTi alloy is smelted with the following raw materials: electrolytic copper, copper-10% chromium master alloy, copper-10% zirconium master alloy, copper-5% lanthanum master alloy, copper-30% zinc master alloy, pure iron, pure titanium. The composition of the alloy is shown in Example 2 of Table 1.

[0032] 1. Melting: Melting with melting equipment used in the industry. The order of alloy addition is: first add electrolytic copper, copper-chromium master alloy, pure iron, pure titanium, smelt for 30 minutes after melting, add copper-lanthanum master alloy for 3 minutes, and finally add copper-zinc master alloy and copper-zirconium intermediate The alloy is smelted for 2 minutes and then cast;

[0033] 2. Hot rolling: After the ingot is peeled, it is heated to 880°C, kept for 3 hours, and subjected to 70% deformation treatment;

[0034] 3. Solution treatment: the alloy is heated to 1000°C for 20 minutes, quenched into water and other fast coolants;

[0035] 4. Cold...

Embodiment 3

[0040] CuCrZrZnCeCoTi uses the following melting alloys: electrolytic copper, copper-10% chromium master alloy, copper-10% zirconium master alloy, copper-5% cerium master alloy, copper-30% zinc master alloy, pure cobalt, and pure titanium. The composition of the alloy is shown in Example 3 of Table 1.

[0041] 1. Melting: Melting with melting equipment used in the industry. The order of alloy addition is: first add electrolytic copper, copper-chromium master alloy, pure cobalt, pure titanium, smelt for 30 minutes after melting, add copper-lanthanum master alloy for 3 minutes, and finally add copper-zinc master alloy and copper-zirconium intermediate The alloy is smelted for 1 minute and then cast;

[0042] 2. Hot rolling: After the ingot is peeled, it is heated to 880°C, kept for 2 hours, and deformed by 70%;

[0043] 3. Solution treatment: The alloy is heated to 960°C for 30 minutes, and then quenched into water and other fast coolants;

[0044] 4. Cold rolling: the alloy is defo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com