Wire frame and the manufacture of resin sealed semiconductor unit with the wire frame

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as mesh blockage, poor installation tightness of mounting substrates, and poor electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

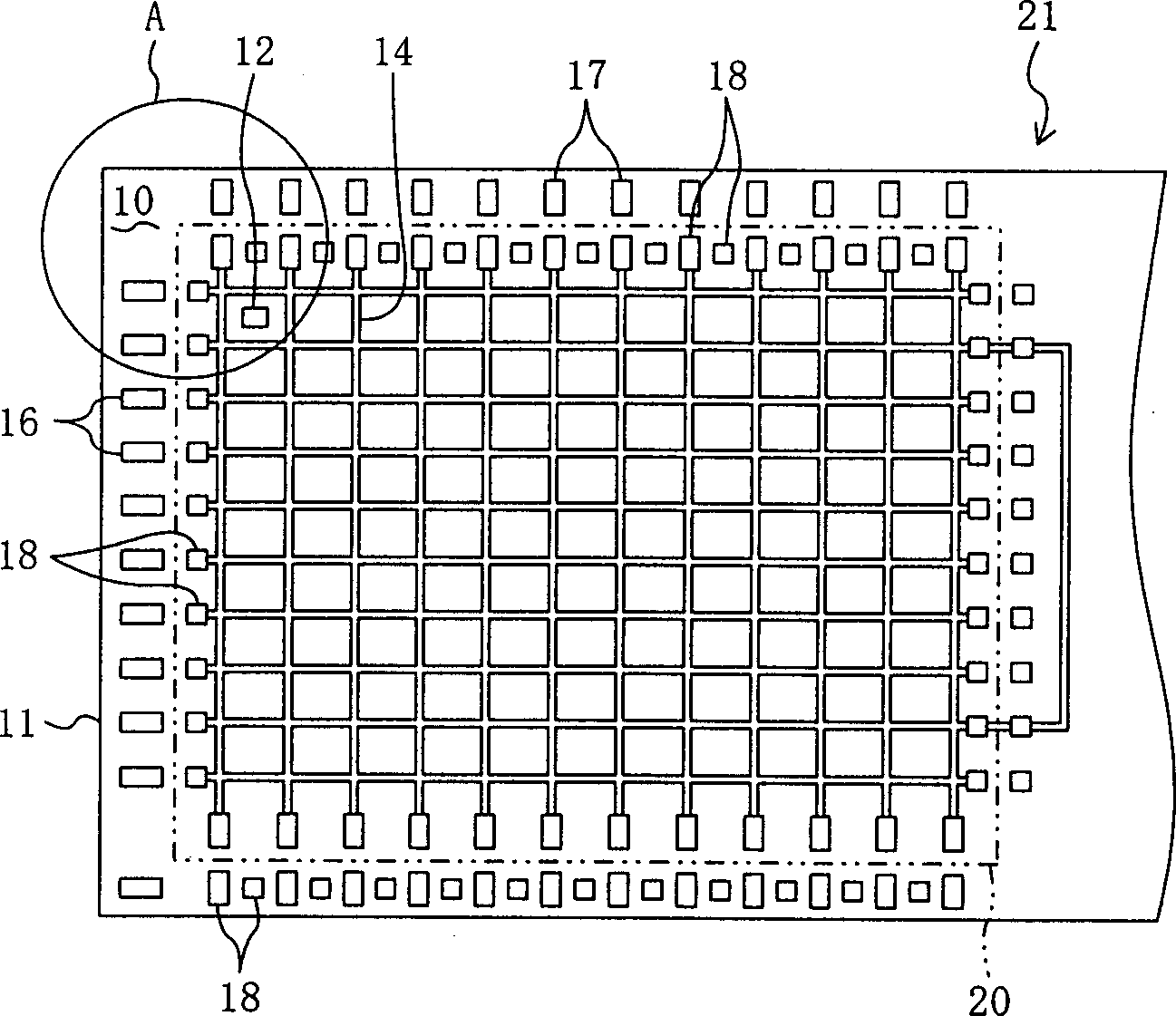

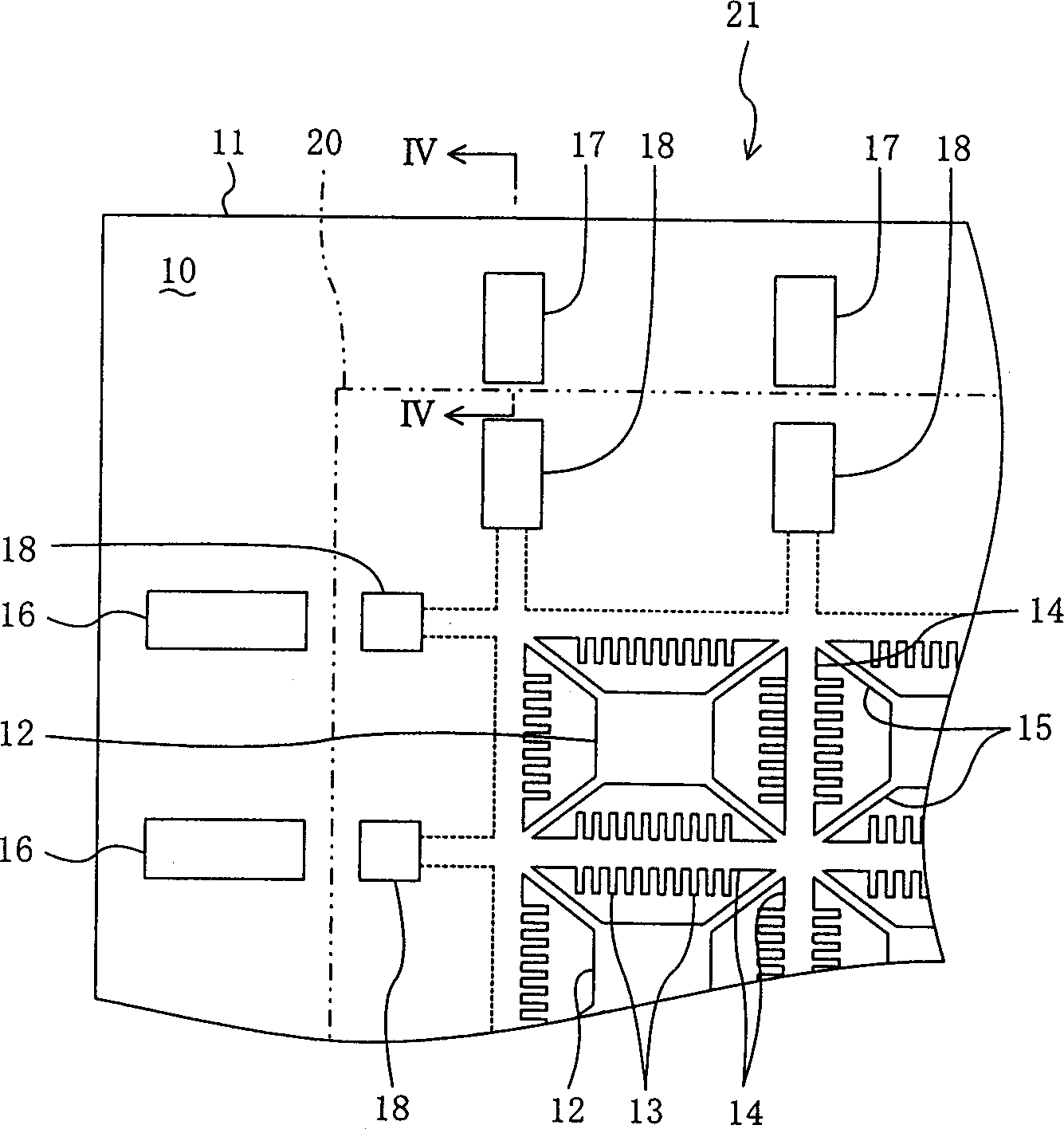

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0041] In a method of manufacturing a resin-sealed semiconductor device by cutting one lead frame of a plurality of semiconductor devices that are resin-sealed with a dicing member such as a dicing blade, while suppressing the occurrence of burrs due to the blade, in order to improve the As a result of many studies on the decrease in productivity due to clogging of blade meshes, the following findings were obtained.

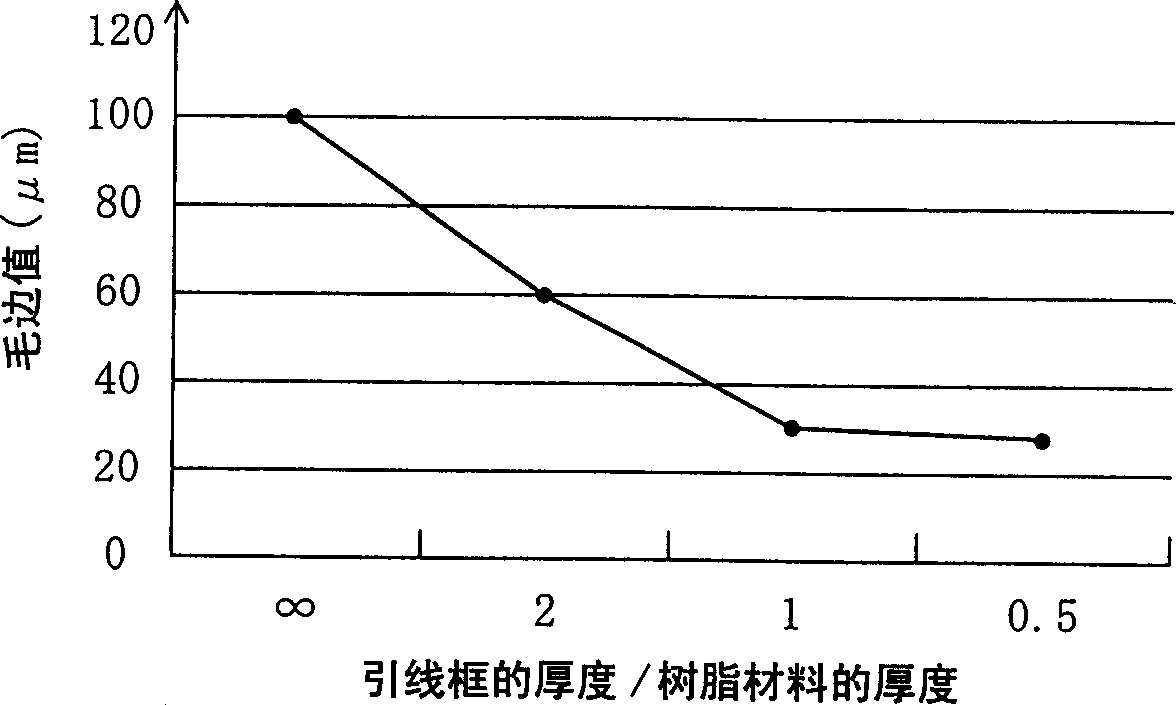

[0042] figure 1 Indicates the relationship between the ratio of the thickness of the lead frame to the thickness of the sealing resin material and the value (height) of burrs generated during cutting. Here, using a lead frame made of copper (Cu) alloy and a cutting blade having a width of 0.1 mm to 0.9 mm, the lead frame to be cut has a width of 0.11 mm to 0.99 mm. As cutting conditions, set the conveying speed of the cutting blade at 10mm / s~1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com