Semiconductor laser light resource for projection apparatus

A technology of projection device and laser light source, which is applied in the field of laser light source, can solve the problems of high cost and complex structure, and achieve the effects of convenient and reliable operation, uniform intensity distribution, simple, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

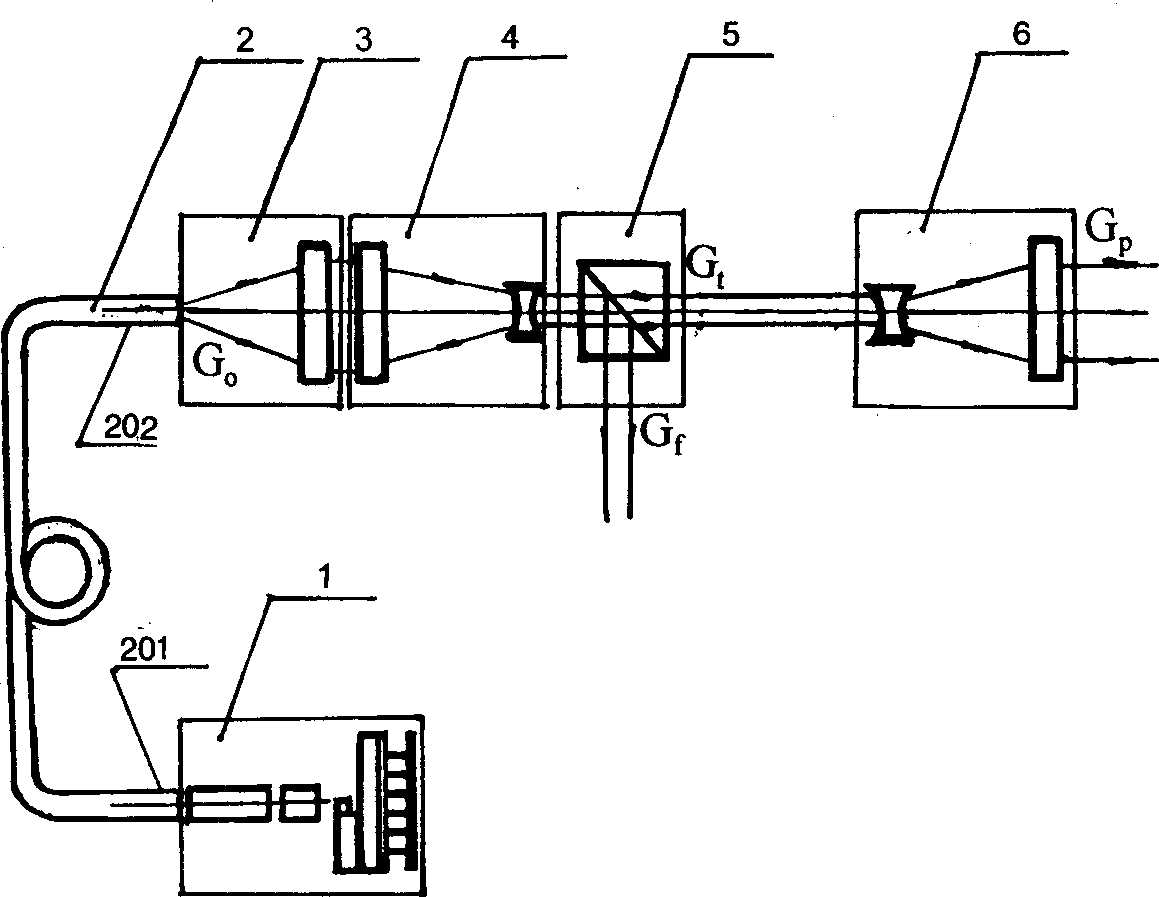

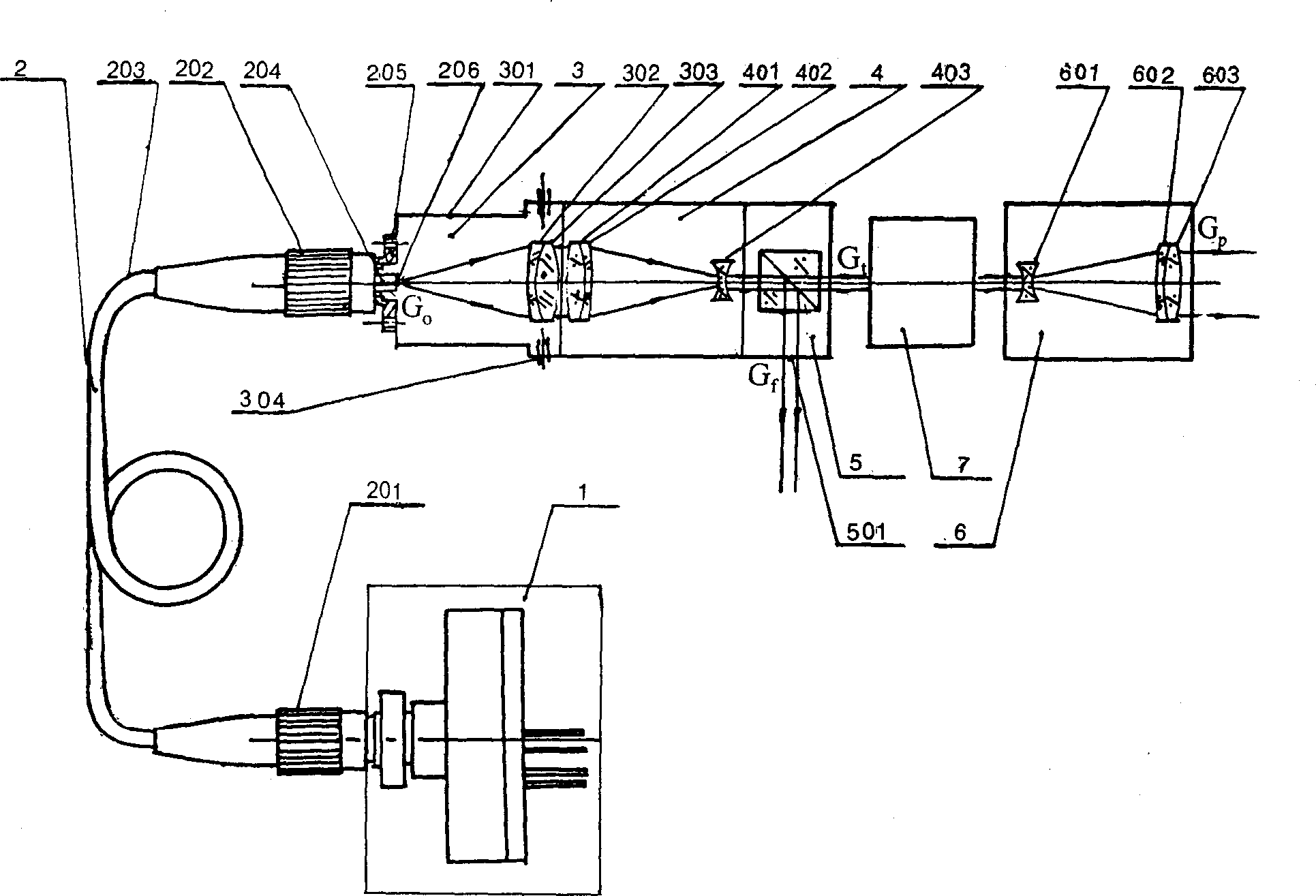

[0017] like figure 1 , figure 2 and image 3 Structure.

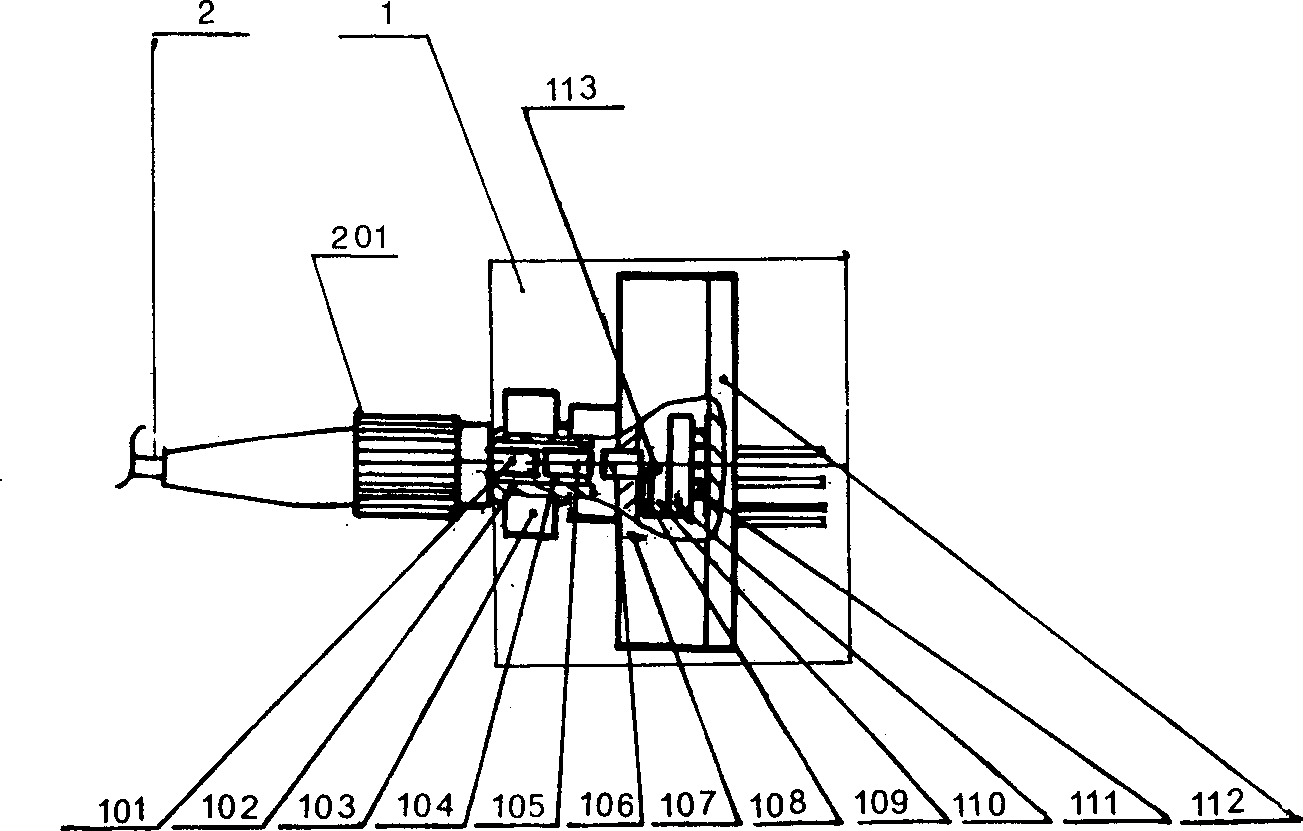

[0018] Wherein the concrete structure of semiconductor laser assembly 1 is as figure 2 shown. The parameters of the semiconductor laser diode 113 are that the light-emitting surface is 100 μm×1 μm, and the beam divergence is θ ⊥ =80°, θ ∥ =12°, laser beam emission wavelength λ=780nm, continuous output (CW) optical power of 1 watt. The size of the collimation module 106 is 2mm×2mm×3mm. After the laser beam emitted by the semiconductor laser diode 113 passes through the collimation module 106, the beam diameter is θ ⊥ ×θ ∥ →0.28mm×0.6mm, after passing through the self-focusing lens 105, the optical power coupled with the single-mode fiber 2 is 696 milliwatts, and the coupling efficiency is 69.6%.

[0019] Wherein the single-mode fiber 2 is made into a fiber optic cable 203, one end has an input connector 201 to connect with the semiconductor laser assembly 1, and the other end has an output connector 202 with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com