Applying method and device for thermal developing sensitive material

A photosensitive material and coating device technology, which is applied in the application of photosensitive materials, photosensitive materials, photosensitive material substrates/auxiliary layers, etc., can solve problems such as stripes and spots, and uneven film thickness of the coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

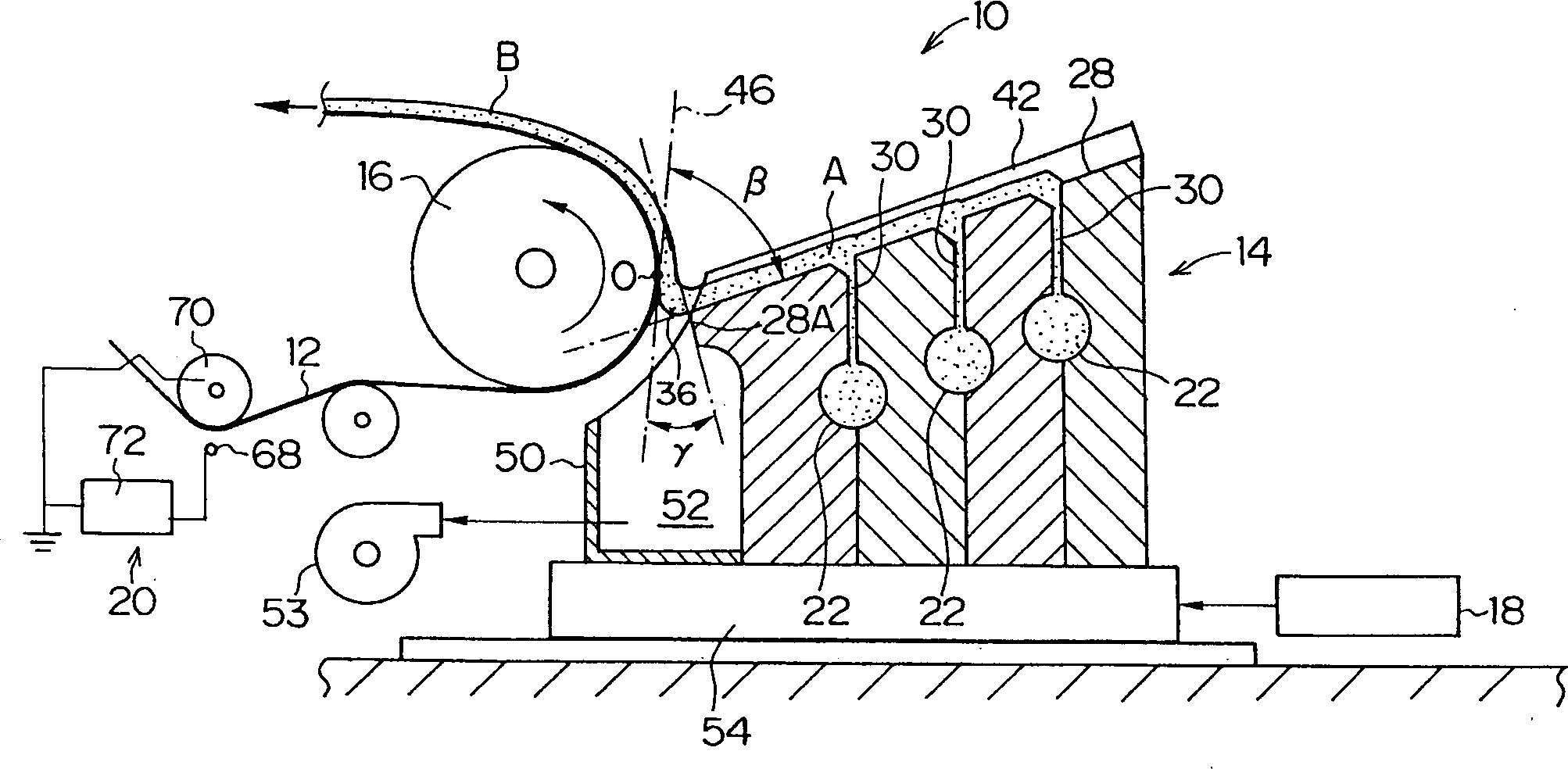

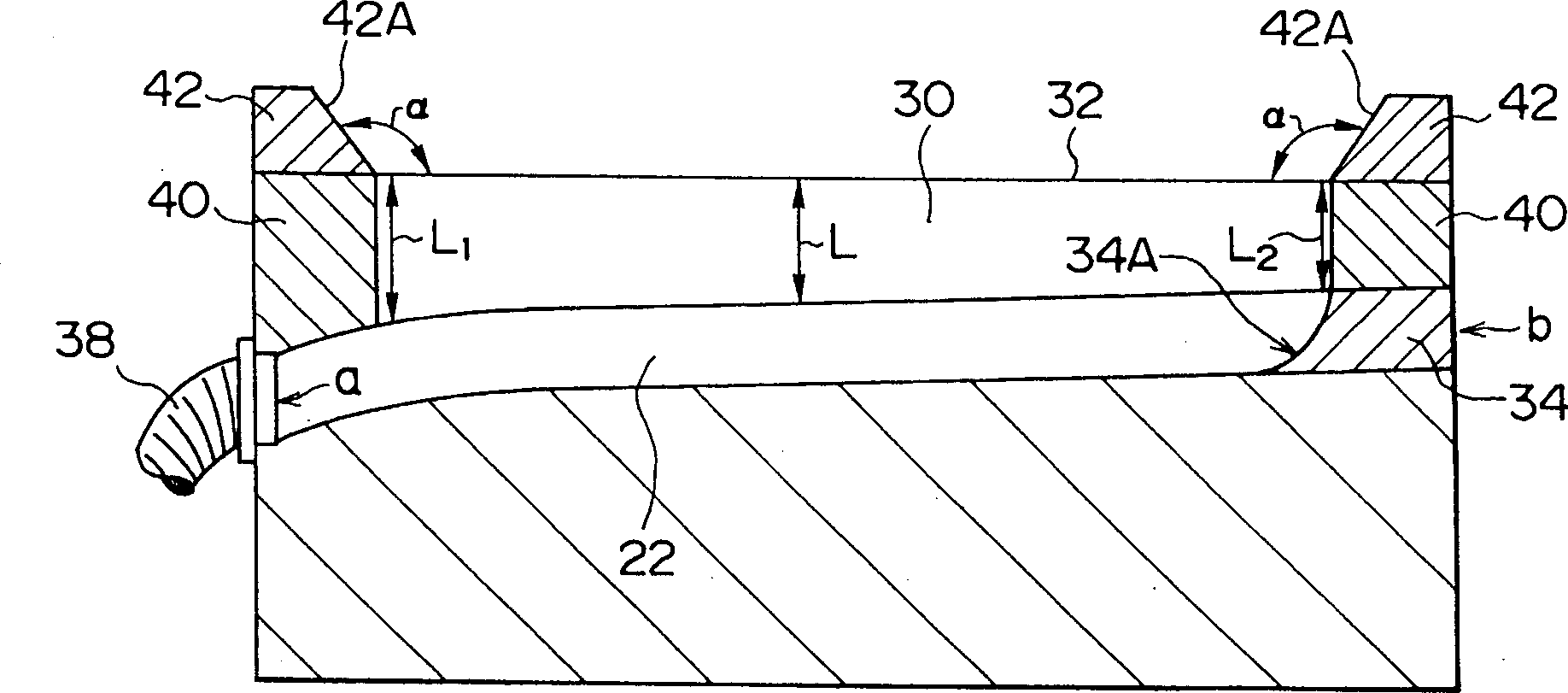

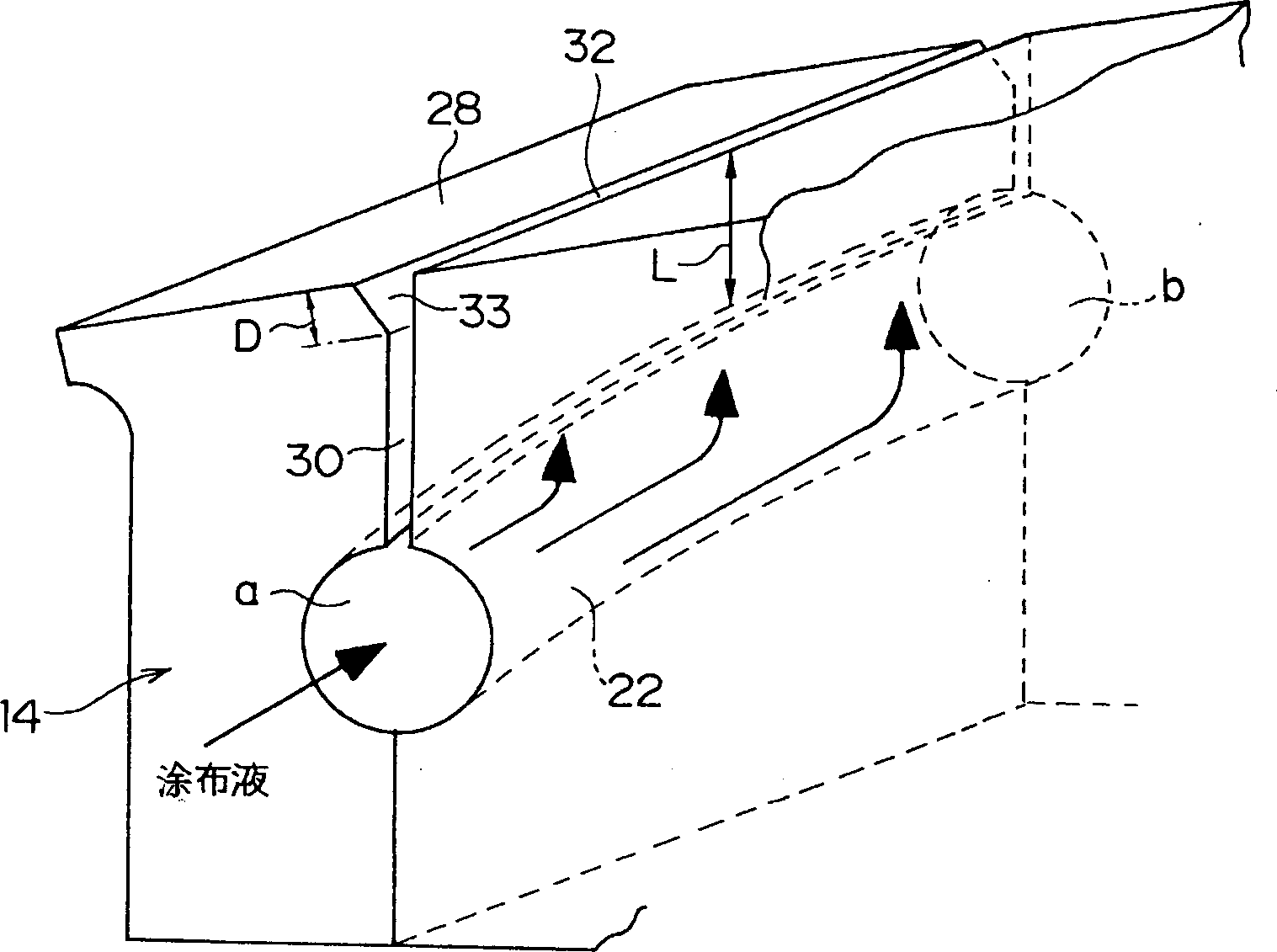

[0018] Hereinafter, the preferred embodiments of the thermally developable photosensitive material coating method and apparatus of the present invention will be described in detail with reference to the accompanying drawings.

[0019] figure 1 A partial cross-sectional view showing the thermally developable photosensitive material coating apparatus 10 of the present invention using the slide 14 . As a thermally developable photosensitive material, it is structurally provided with at least one photosensitive layer containing at least one organic acid silver and at least one hydrophobic polymer latex used as a binder on the substrate 12, and on the side of the photosensitive layer opposite to the aforementioned substrate One or more non-developing recordable protective layers with at least one water-soluble polymer as a binder on the opposite side, in this embodiment, to form a photosensitive layer, an intermediate layer and a protective layer, three layers are simultaneously co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com