Liquid phase flow battery pile of Fe/Cr system

A fluid battery, liquid phase technology, applied in fuel cells, fuel cell components, circuits, etc., can solve the problems of large current loss, incomplete utilization of carbon felt area, limited current sharing effect, etc., to improve current efficiency , Improve the effect of electrolyte flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

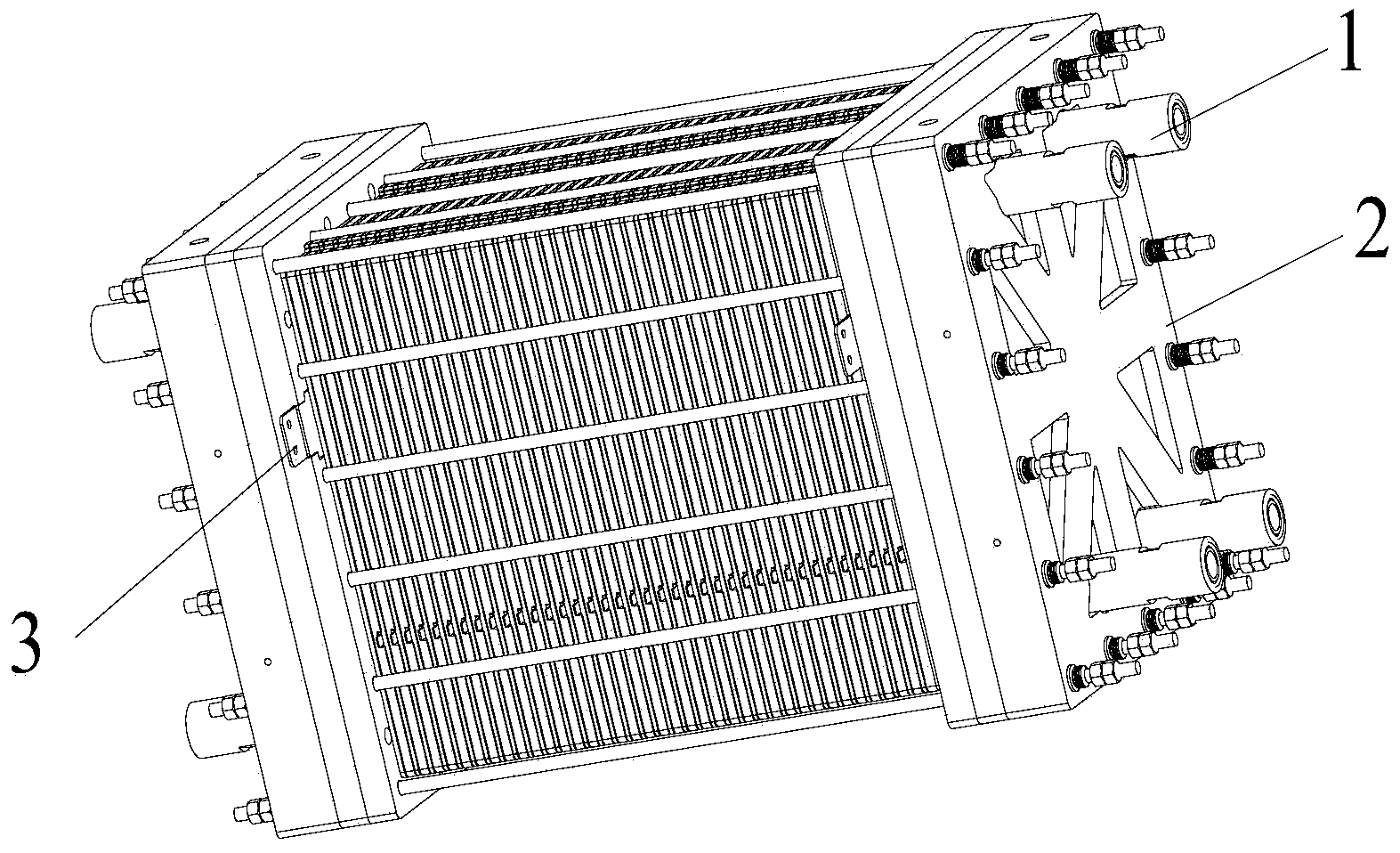

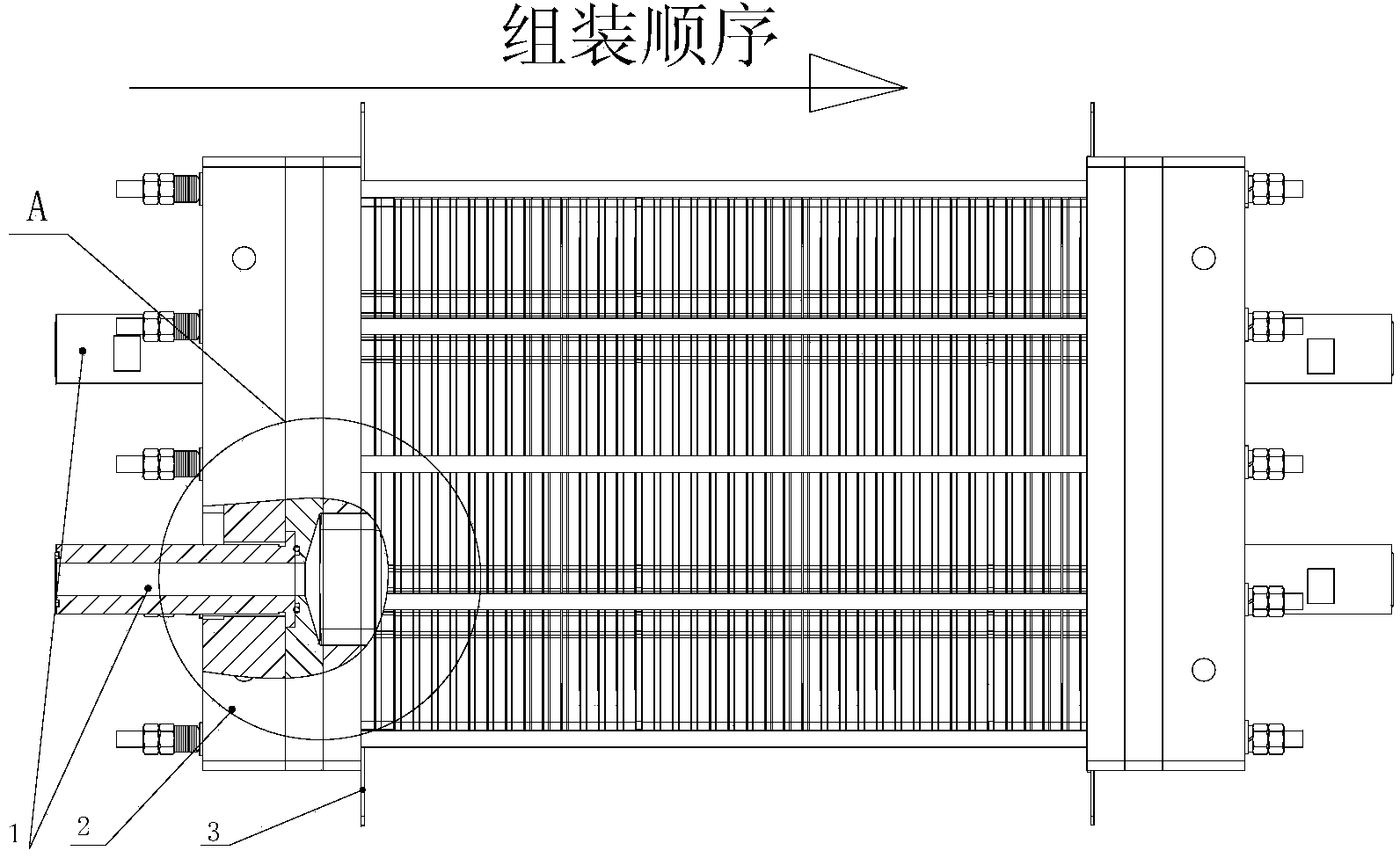

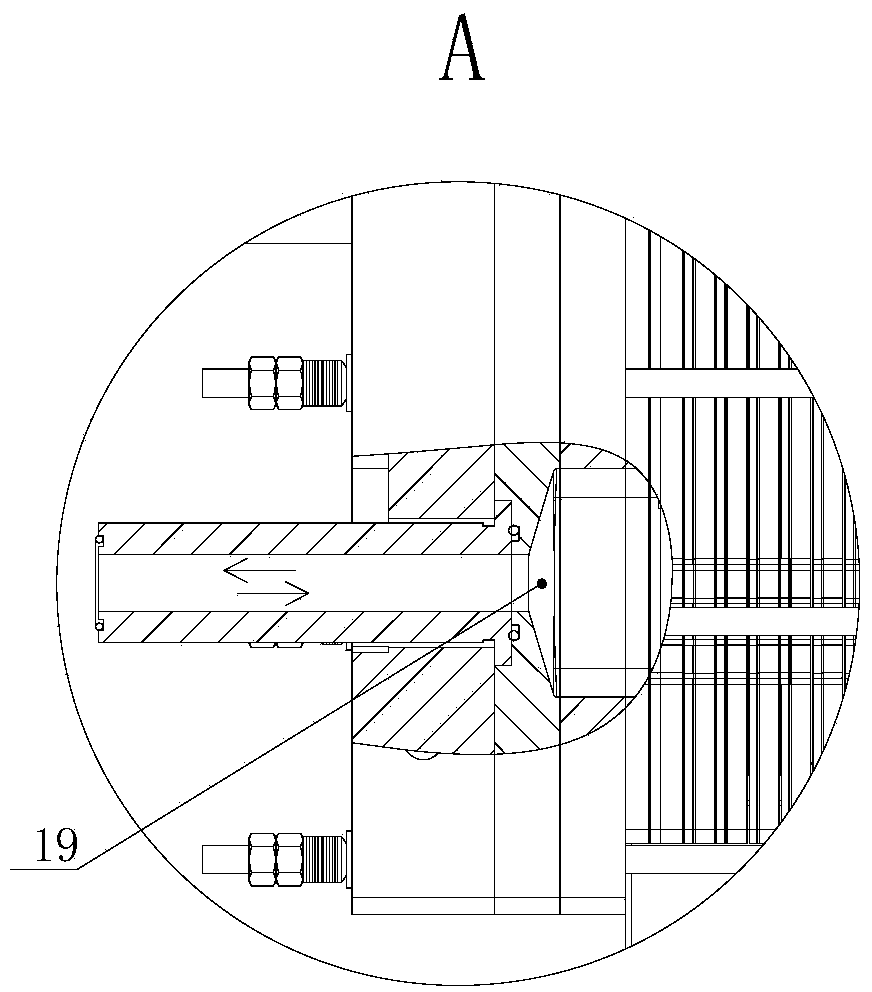

[0037] An Fe / Cr system liquid-phase flow battery stack is composed of 40 single cells connected in series, and each single cell includes a positive electrode and a negative electrode, a diaphragm, a positive electrode electrolyte and a negative electrode electrolyte, and the iron-chromium redox flow battery is respectively Fe in different valence states 2+ / Fe 3+ , Cr 2+ / Cr 3+ As the redox of the positive and negative poles of the battery, the positive and negative electrolytes are stored in two liquid storage tanks respectively, and the active electrolyte is driven by an acid-resistant liquid pump to the reaction site (battery stack) and then returned to the liquid storage tank to form a cycle. Liquid flow circuit to realize the charging and discharging process. Both sides of the cell stack are clamped by end plates 1, and there are cell stack interfaces 1 on the end plates, which are positive electrolyte inlet, negative electrolyte inlet, positive electrolyte outlet, and...

experiment example 1

[0052] Experimental example 1: Runner structure test

[0053] A single cell was assembled from battery components of the same size as in Example 1, and the end plates were made of transparent plastic for easy observation. The flow channel on the plate frame includes a shared channel, two parallel serpentine flow channels, an equalizing groove, a flow equalizing bell mouth and a flow equalizing groove, but there is no equalizing island in the middle of the equalizing groove. The circulation pump is used to drive the electrolyte to enter the single cell through the shared channel, and enter the serpentine flow channel through the flow channel inside the plate. The terminal of the serpentine flow channel is divided into 4 bell mouths, so the flow of electrolysis into the bell mouth is uneven. Causes uneven distribution of electrolyte on the carbon felt (electrode).

Embodiment 2

[0055] An Fe / Cr system liquid-phase flow battery stack is composed of 50 single cells connected in series, and each single cell includes a positive electrode and a negative electrode, a diaphragm, a positive electrode electrolyte and a negative electrode electrolyte, and the iron-chromium redox flow battery is respectively Fe in different valence states 2+ / Fe 3+ , Cr 2+ / Cr 3+ As the positive and negative poles of the battery redox. The stack structure is the same as in Example 1.

[0056] Positive plate frame size: length 650mm, width 460mm, thickness 11mm.

[0057] Negative plate frame size: length 650mm, width 460mm, thickness 7mm.

[0058] Diaphragm size: length 390mm, width 435mm.

[0059] Carbon felt size: length 360mm, width 223mm, thickness 7.5mm. Cover area is 122cm 2 .

[0060] The shared passage takes the form of an "O" ring seal. The diaphragms are sealed on both sides and positioned relative to each other. The bipolar plates are wrapped and sealed. Ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com