Stable non-aqueous single phase viscons vehicles and formulations utilizing such vehicles

A non-aqueous, carrier-based technology, applied in the field of stable uniform mixed preparations, which can solve problems such as toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Preparation of non-aqueous single-phase viscous vehicles

[0095]The non-aqueous single-phase adhesive vehicles will be prepared below and are shown in the table below. A. Glyceryl monolaurate (Danisco Ingredients, New Century, Kansas) (25 g) was dissolved in lauryl lactate (ISP Van Dyk Co., Belleville, NJ) (35 g) at 65°C. Polyvinylpyrrolidone C30 (BASF, Mount Olive, NJ) (40 g) was added and the mixture was mixed with a double helical blade mixer (D.I.T) at 40 rpm until a single phase was obtained. Vacuum was used in the mixing chamber to remove air bubbles. Remove the single-phase support from the mixer and allow to cool to room temperature. B. Glyceryl monolaurate (Danisco Ingredients, New Century, Kansas) (25 g) was dissolved in lauryl lactate (ISP Van Dyk Co., Belleville, NJ) (35 g) at 65°C. Polyvinylpyrrolidone C17 (BASF, Mount Olive, NJ) (40 g) was added and the mixture was mixed with a double helical blade mixer (D.I.T) at 40 rpm until a single pha...

Embodiment 2

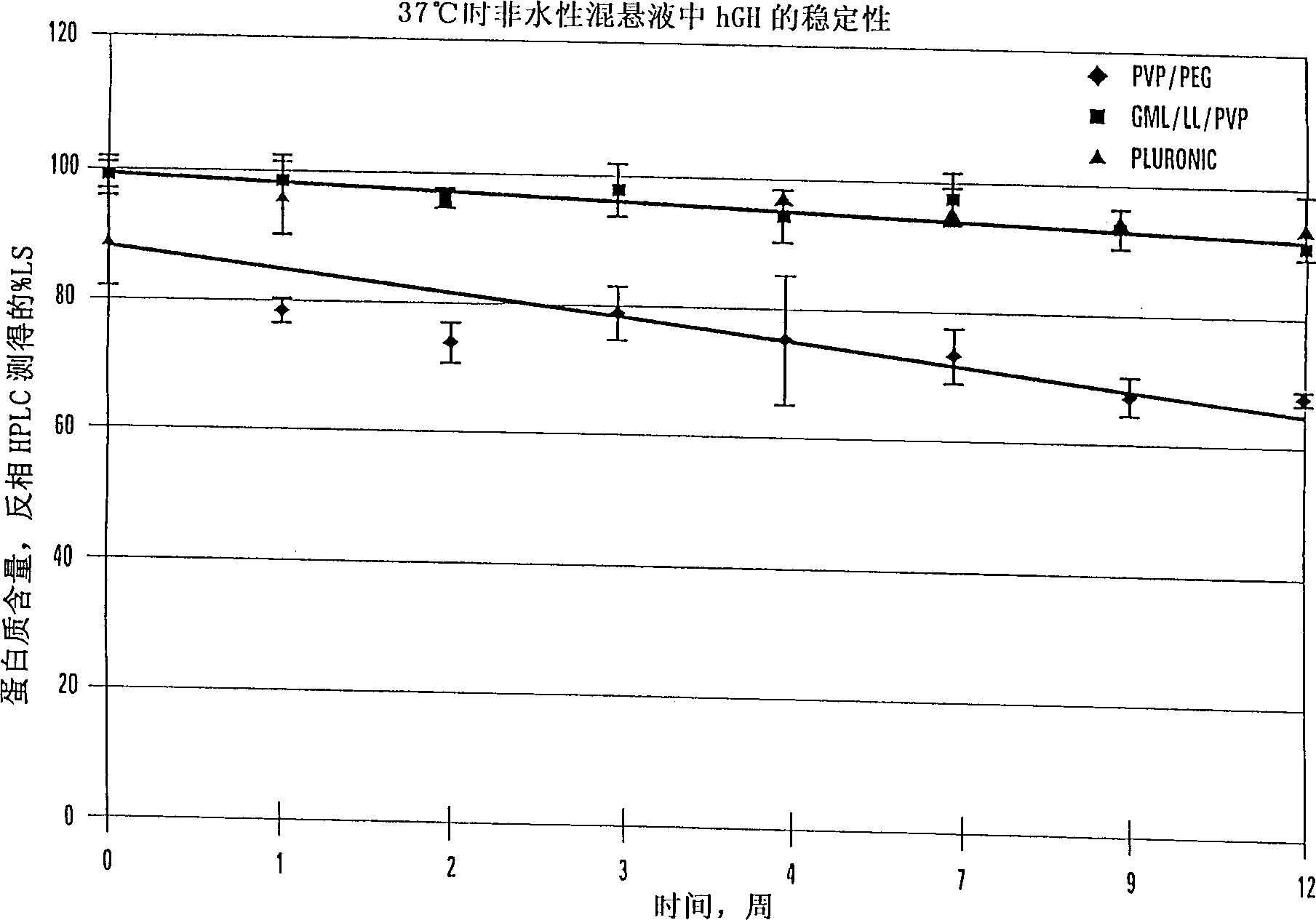

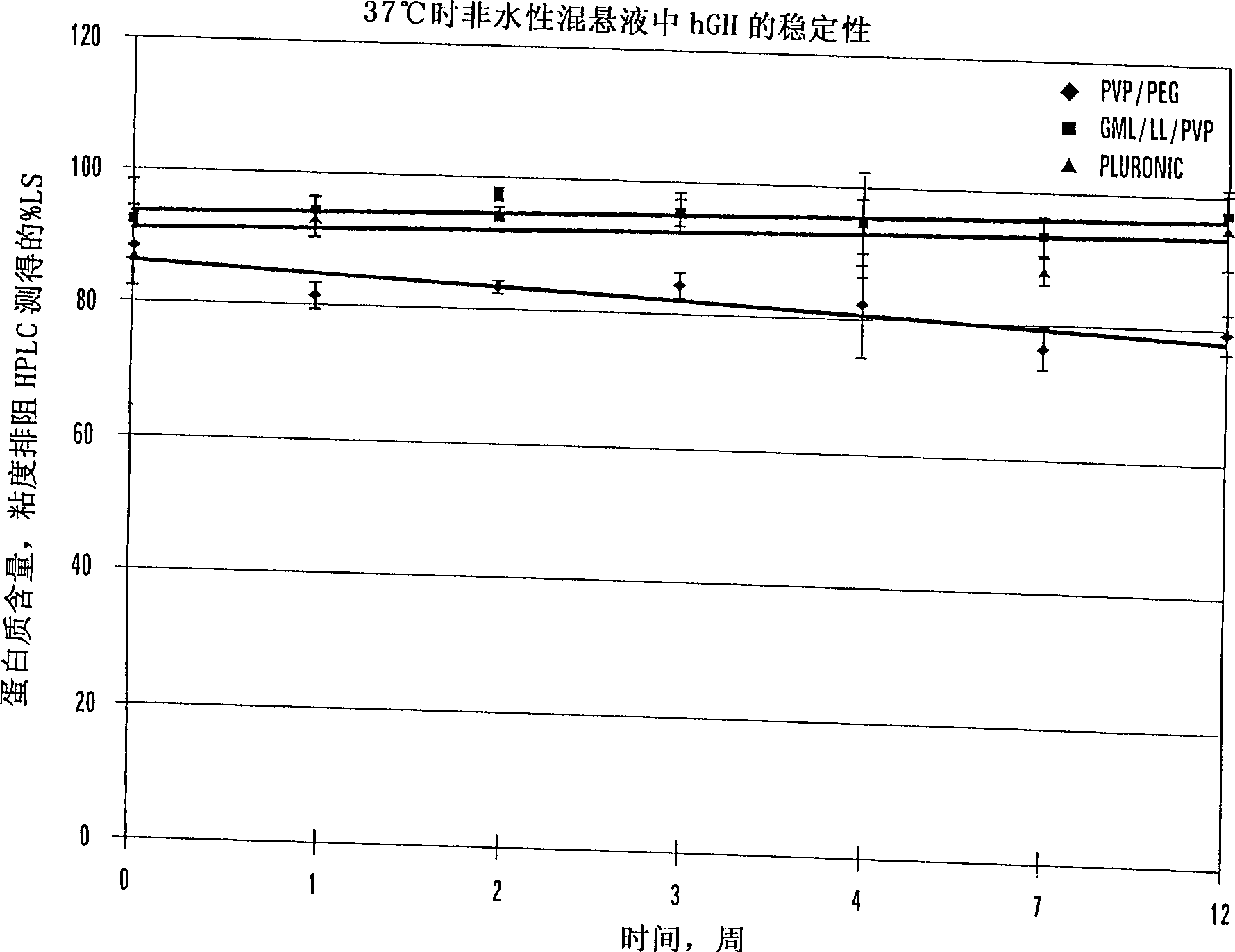

[0105] hGH

[0106] A. Preparation by spray drying method

[0107] Lyophilized hGH (BressaGen, Adelaide, Australia) was reconstituted with 150 ml deionized water. This stock solution contained 1050 mg hGH. Use Amicon Diaoflo Ultrafiltration membranes (molecular weight cut-off 1000) were used for buffer exchange. The ultrafiltration cell was connected to an auxiliary reservoir containing 5 mM phosphate buffer (pH 7). The fluid volume of the ultrafiltration cell and the concentration of hGH were kept constant as the phosphate buffer replaced the excipients.

[0108] The ultrafiltered protein solution (wherein the protein concentration is about 2%) was spray dried with a YAMATO small spray dryer. The settings of the spray dryer are as follows: the aspiration pressure is usually set at 1.3kgf / cm 2 , the inlet temperature was 120° C., and the spray rate was 2.5 (about 3 ml / min). Collect the powder with the collector's centrifugal catcher. Handling of t...

Embodiment 4

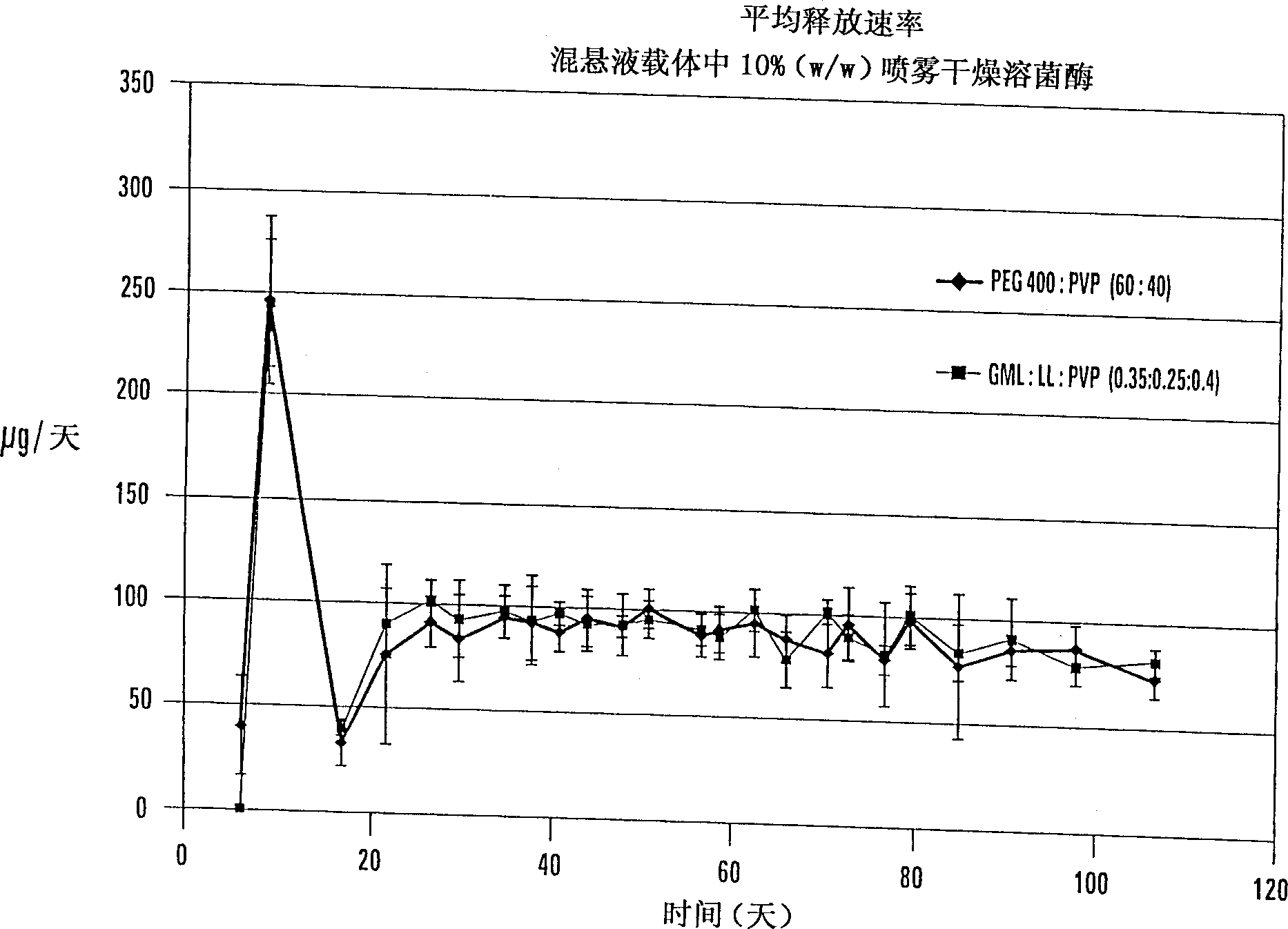

[0126] preparation depot

[0127] release rate graph

[0128] A titanium depot system implanted in a drug delivery device (as disclosed in patent application US08 / 595761, incorporated herein by reference) was equipped with an osmotic engine, a piston, and a release-controlling membrane. The appropriate amount of viscous carrier formulation is filled into the reservoir and plugged with a flow plug. The system was placed in a 37°C water bath to allow sustained release of the formulation. Released substances were sampled twice a week. Released substances were analyzed by reversed-phase high-performance liquid chromatography. Concentrations of beneficial substances in each system were converted into daily releases. Such as Figure 3-8 As shown, the release of the beneficial agent from the implanted drug delivery device is zero order release.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com