Method of manufacturing a diamond composite and a composite produced by same

A composite material and diamond technology, which is applied in the field of preparing diamond composite materials, can solve problems such as damage to diamond and composite materials, difficulty in pore size silicon impregnation, and local temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

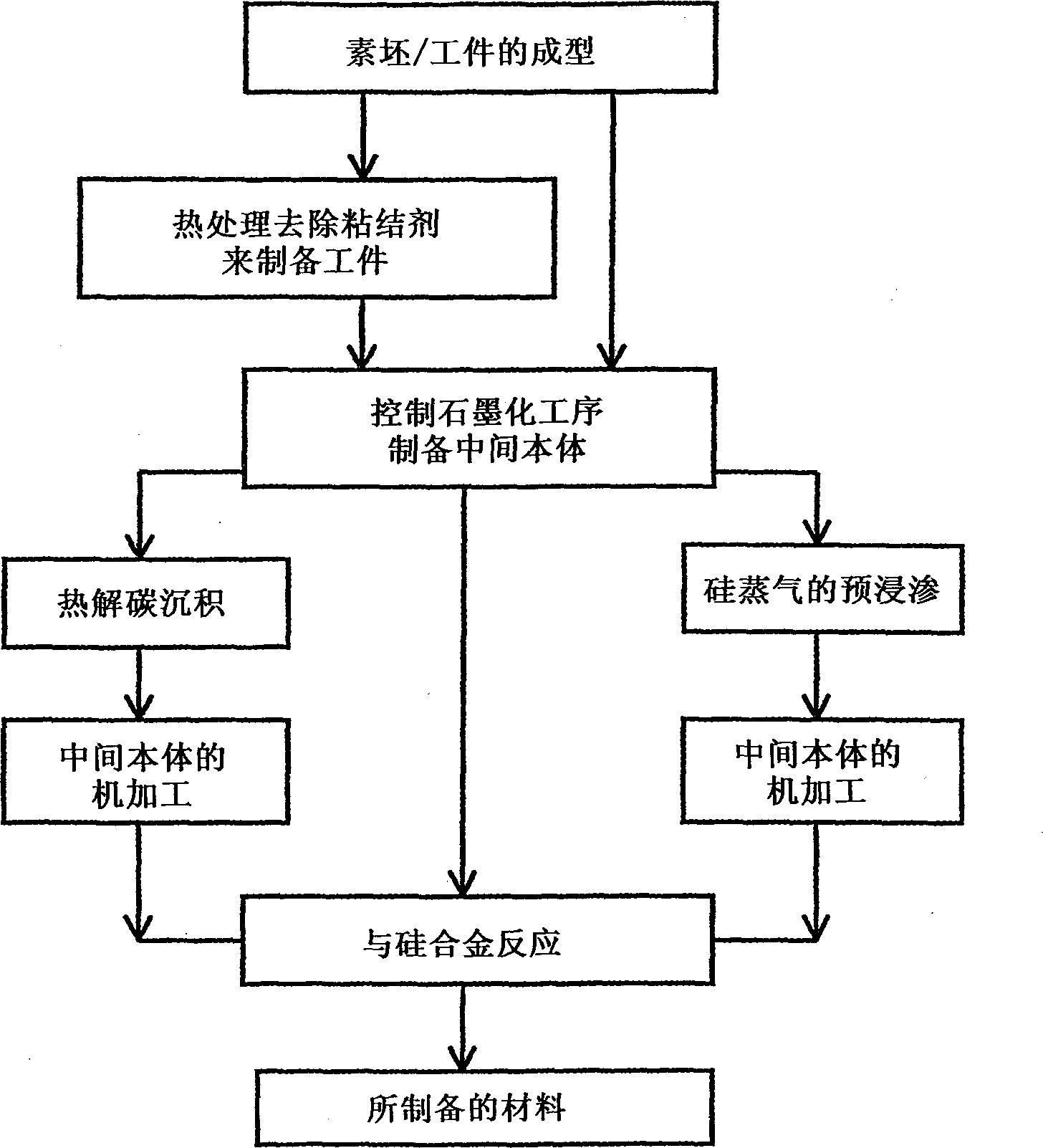

[0085] The workpiece is produced by evaporation or hardening and decomposition of the solution medium and / or binder present in the green body. If the green body is prepared without a binder, it can be considered a workpiece. The final amount of binder in the workpiece is 5% by weight or less. To ensure uniform and controlled graphitization throughout the workpiece volume, it is undesirable to have impurities from the binder in it. These may catalyze or prevent the graphitization process. The reason for having no less than 95% by weight diamond in the workpiece is to precisely control the amount of carbon present and this is only possible with no fillers and a minimum amount of binder in the green body.

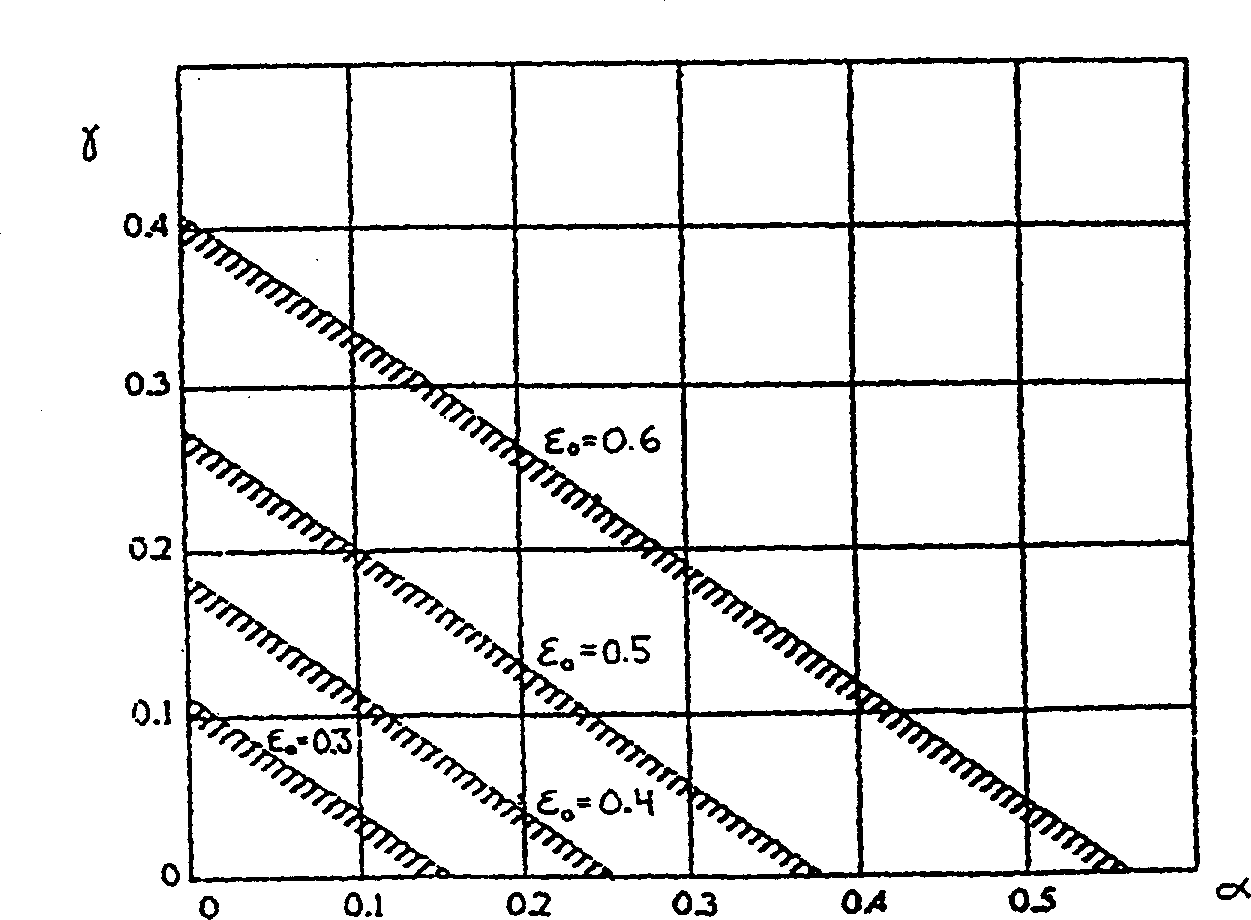

[0086] Heat treatment of workpieces to obtain intermediate bodies. A workpiece with a diamond content of 95-100% by weight of the total mass is heat treated to obtain an intermediate body with controlled diamond graphitization, or optionally a combination of controlled diam...

Embodiment A

[0206] 1. A mixture of the following substances is formed: diamond fine powder of ACM28 / 20 and binder—25% ethanol solution of phenolic resin—the amount of dry resin accounts for 2% by weight of the diamond powder mass. The mixture was stirred well and passed through a 200 micron sieve.

[0207] 2. Forming of strips with a length of 50 mm and a rectangular cross-section of 6 × 5 mm was done by pressing with a metal mold under a load of 45 kN at room temperature.

[0208] 3. The green body was released from the mold, kept in air at room temperature for 10 hours, then dried at 70°C for 1 hour and hardened at 150°C for 1 hour. The prepared workpiece contained 98% by weight diamond (56% by volume) and had a porosity of 41% by volume.

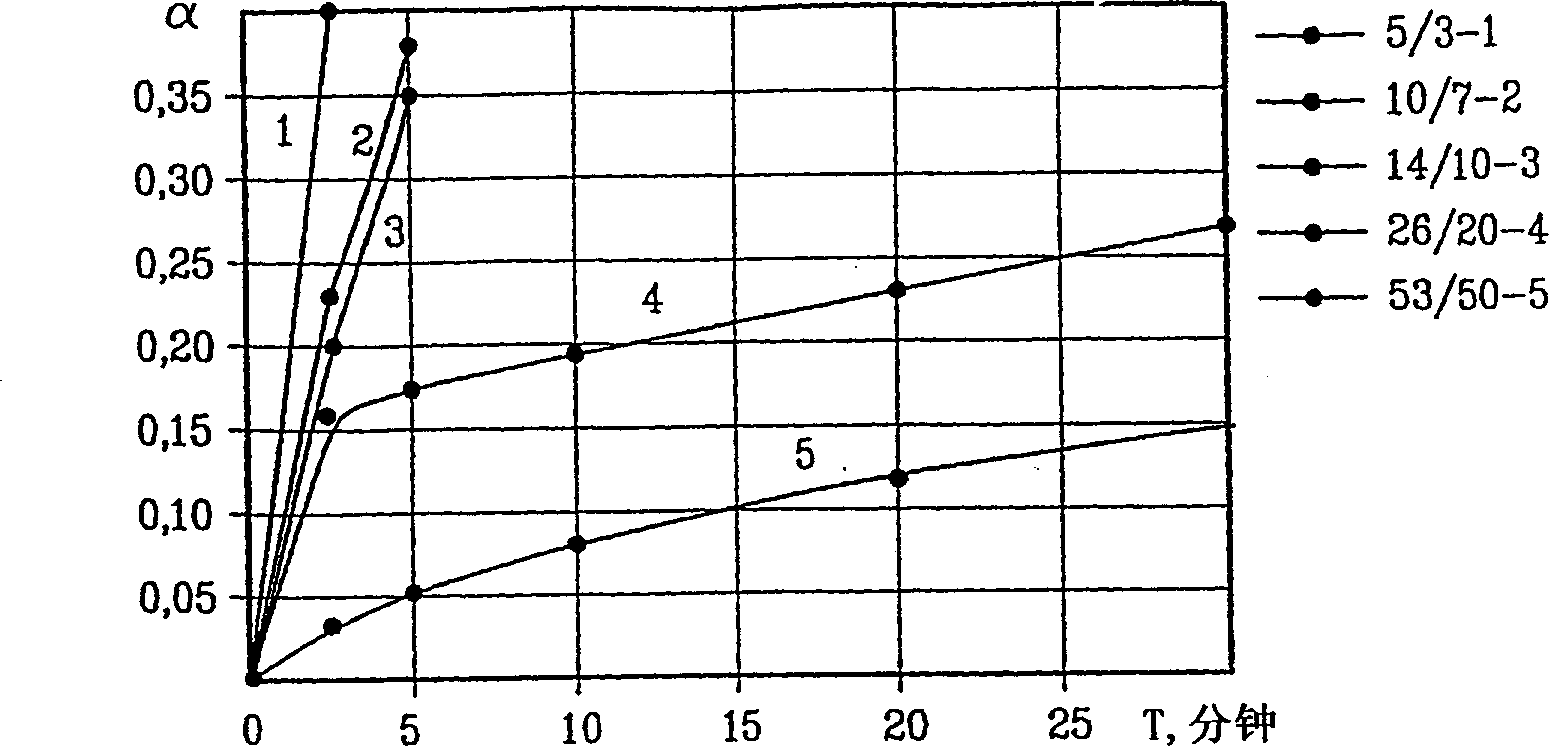

[0209] 4. Heat treatment of the samples was carried out at 1550° C. under vacuum (pressure 0.1 mmHg). Sample no1 was heated for 3 minutes, sample no2 was heated for 10 minutes, sample no3 was heated for 20 minutes, and sample no4 was heated for...

Embodiment B

[0215] Sample no1 was prepared with diamond powder ACM10 / 7, sample no2 was prepared with diamond powder ACM14 / 10, sample no3 was prepared with diamond powder AcM28 / 20 and sample no4 was prepared with a mixture of diamond powders ACM 63 / 50 and AcM10 / 7. Bars with dimensions 5 x 6 x 50 mm were formed using a temporary binder and diamond powder. The workpiece is heated and vacuum heat-treated at 1550°C, and then impregnated with liquid silicon. Measure Young's modulus.

[0216] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com