Method and apparatus for manufacturing a rare-earth metal doped optical fiber preform

A preform and equipment technology, applied in glass manufacturing equipment, light guides, manufacturing tools, etc., can solve problems such as difficult doping of rare earth dopants, achieve high pump power absorption, low core attenuation rate, numerical aperture small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] An optical fiber preform was prepared using the basic glass deposition components and parameters in Table 1.

[0097] cladding formation

(1450℃ hot zone, 3 passes)

(1450℃ hot zone, 4 passes)

components

flow

components

flow

SiCl 4

500cc / 20℃, 1.1g / min

SiCl 4

200cc / 22℃, 0.66g / min

GeCl 4

25cc / 20℃, 0.03g / min

POCl 3

687cc / 20℃, 0.16g / min

POCl 3

30cc / 20℃, 0.007g / min

SF 6

0.8cc / min

SF 6

0.25cc / min

O 2

1,000cc / min

O 2

1,000cc / min

he

1,000cc / min

he

1,000cc / min

[0098] * Sintered at 1960°C

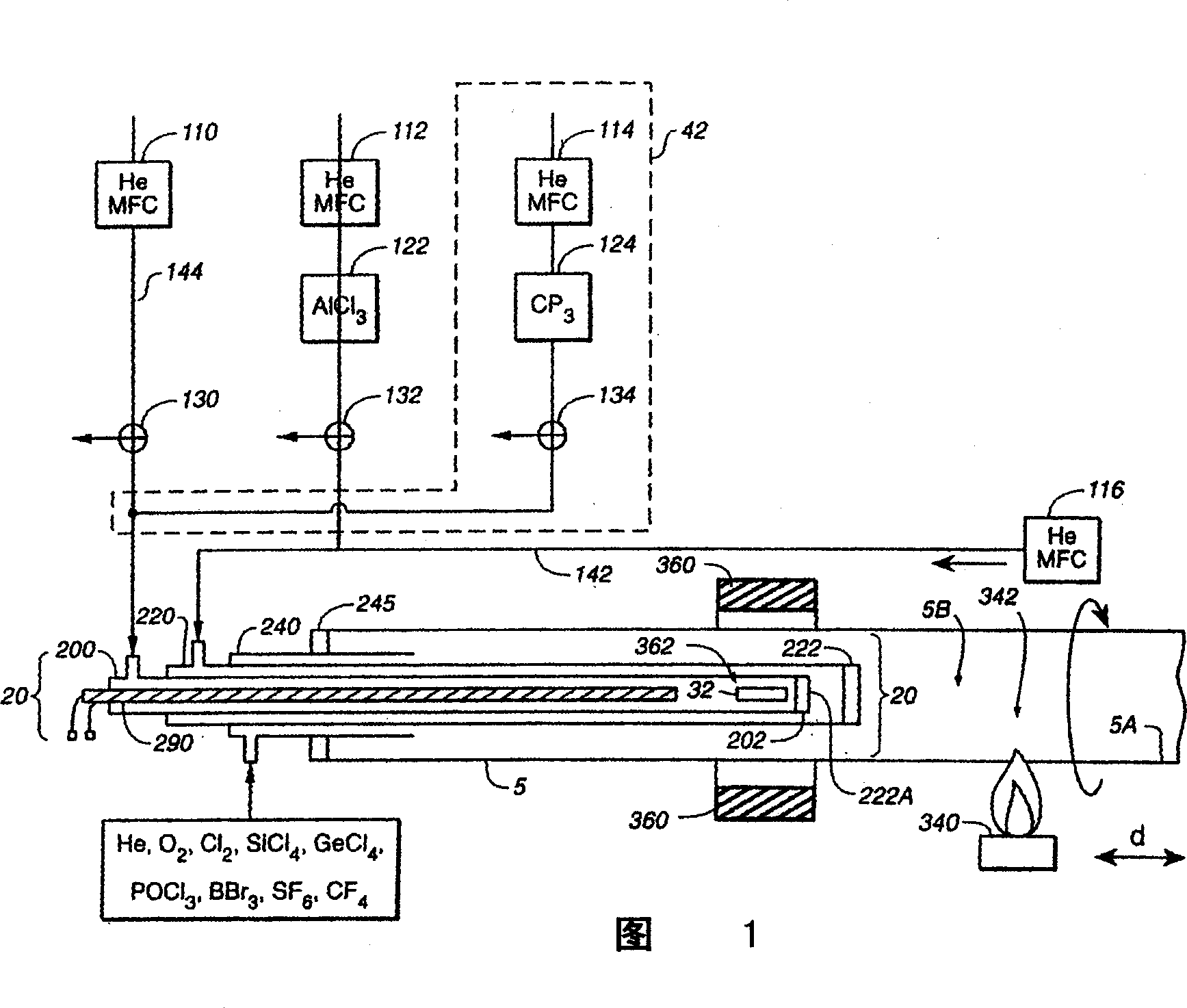

[0099] More specifically, during the deposition process, a stream of glass-forming component vapor containing the above-mentioned components is introduced into the cavity of the quartz tube 5 through the outer delivery tube 240 of the multiple concentric delivery system 20 of FIG. 1, and reacts to form a powd...

Embodiment 1A-1C

[0103] Three kinds of optical fiber preforms (Examples 1A-1C) were prepared by the method of Example 1. However, the ytterbium chloride in Example 1A vaporizes at 930°C, in Example 1B at 950°C, and in Example 1C at 980°C. It is observed that the core depositions of Examples 1A-1C are the same, but the content of ytterbium oxide increases from 1A to 1C, that is, increases with the increase of gasification temperature. The concentration of ytterbium oxide in Example 1C exceeds 3 wt%. Example 1D

Embodiment 1D

[0104] An optical fiber preform was prepared by the method of Example 1. However, in this embodiment, the core layer is formed not by 4 passes but by 8 passes. The core composition of the obtained optical fiber preform is similar to that of the preform of Example 1, but the core diameter is larger, so it is more suitable for drawing multimode optical fiber. Example 1E

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com