Wafer inspection method and wafer inspection device

A detection method and a detection device technology, which are applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of affecting the detection accuracy, large volume of incident light system, and occupying a large space, so as to improve detection efficiency and increase The effect of large detection signal and reduced design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following description, many specific details are explained in order to fully understand the present invention. However, the present invention can be implemented in many other ways different from those described here, and those skilled in the art can make similar popularizations without violating the connotation of the present invention. Therefore, the present invention is not limited by the specific implementation disclosed below.

[0055] Secondly, the present invention is described in detail using schematic diagrams. When describing the embodiments of the present invention in detail, the schematic diagrams are only examples, which should not limit the scope of protection of the present invention.

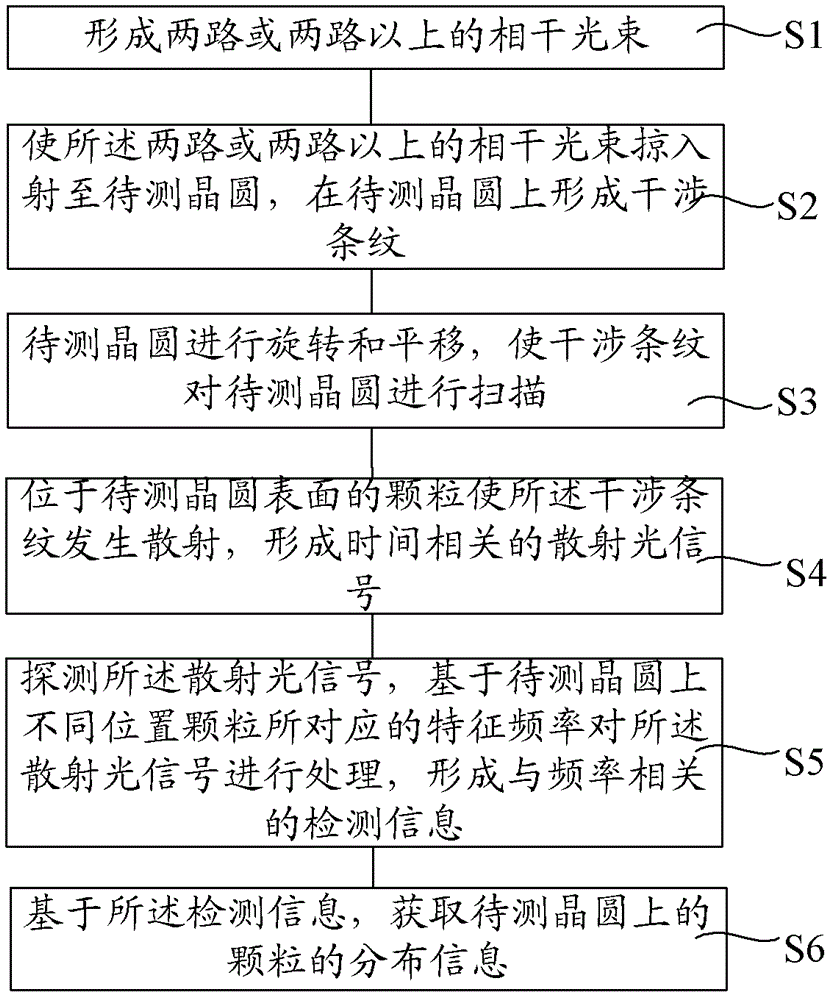

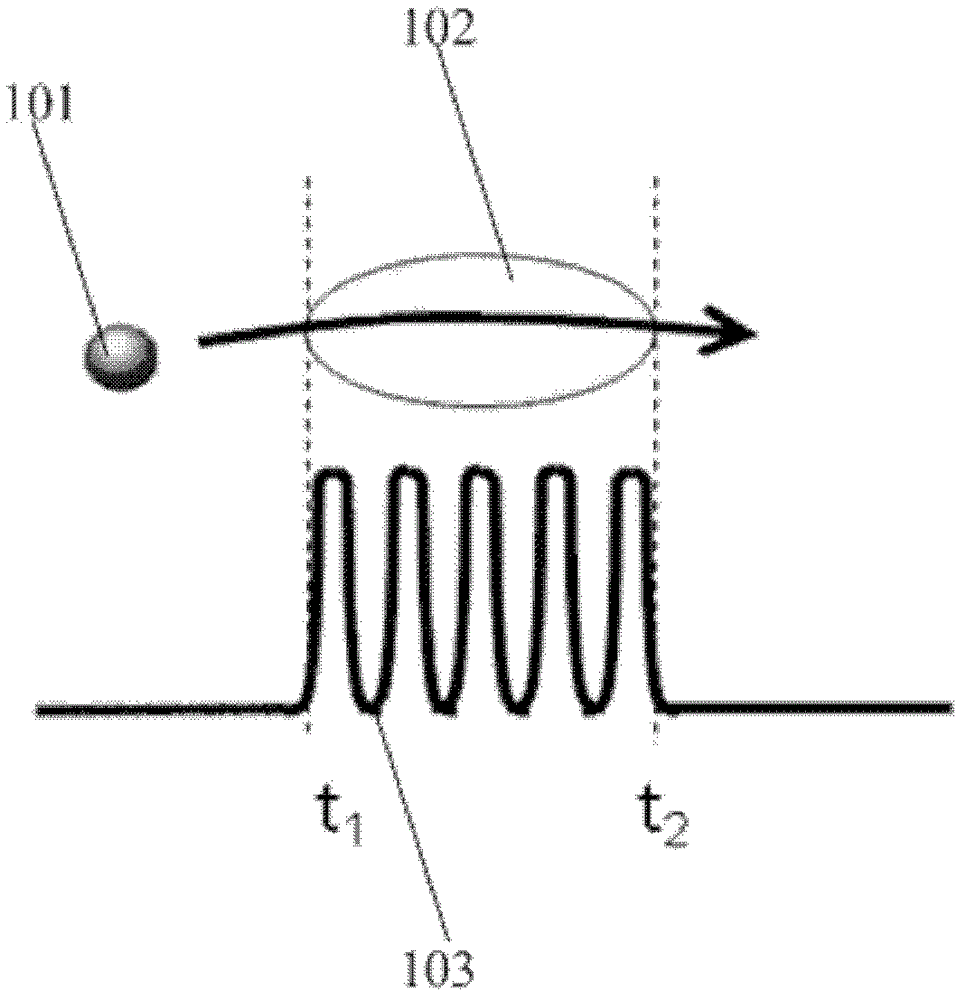

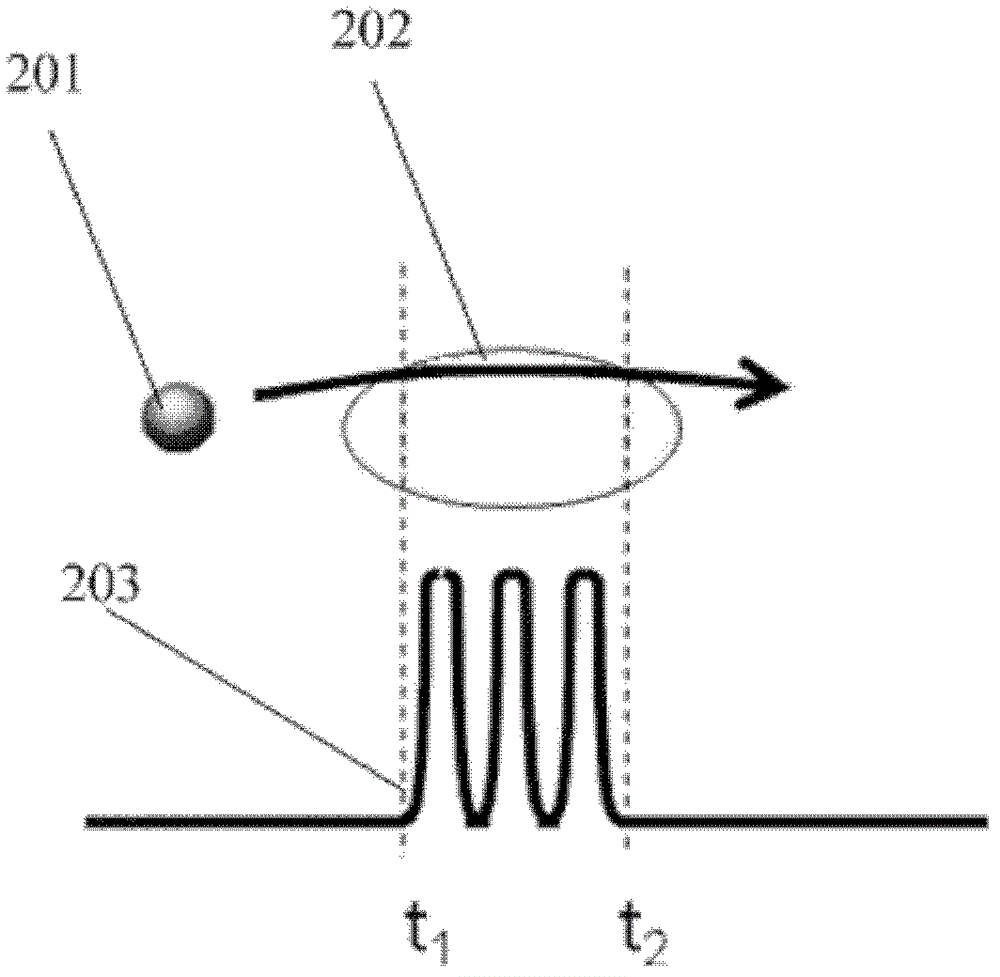

[0056] In order to solve the problems of the prior art, the present invention provides a wafer inspection method, including: forming two or more coherent beams; making the two or more coherent beams grazing incident on the wafer to be tested , The interference fringes are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com