Biological pulping method for non-wood fiber plant

A non-wood fiber and biological pulping technology, which is applied in the field of pulp manufacturing, can solve the problems of uneconomic benefits, long time for inoculating white rot fungi to treat wood, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The non-wood fiber plant (waste straw) biopulping method of the present invention will be fully understood by the following examples, so that those skilled in the art can complete it accordingly, but the present invention is not limited to the following examples .

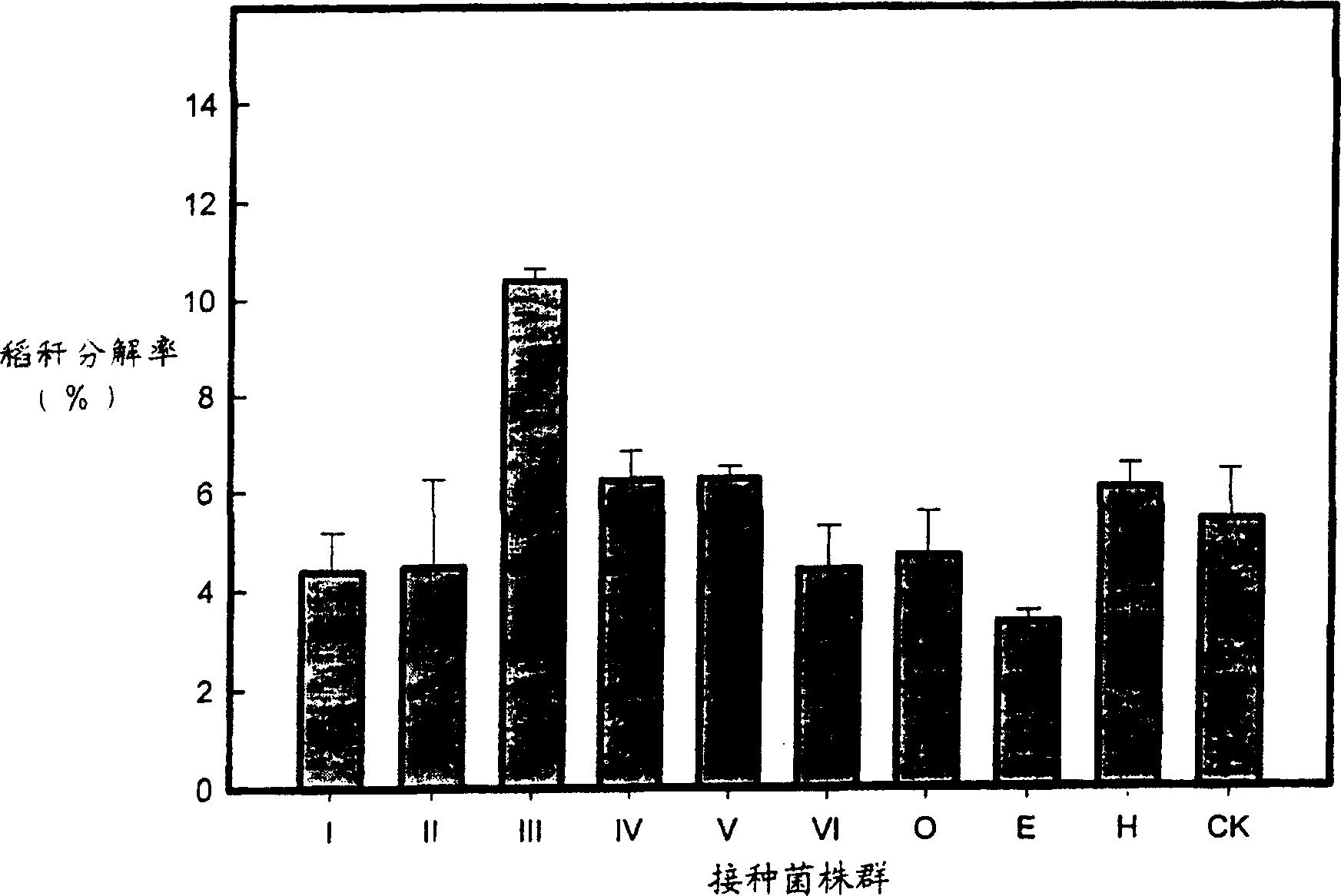

[0030] (1) The effect of different treatment methods on decomposing straw stalks

[0031] In a preferred embodiment of the present invention, the straw stalks can also be processed in different ways, such as utilizing high temperature and high pressure sterilization (121°C, 15lb / in 2 , 15 minutes), high-temperature steam (100°C, 30 minutes), fumigant fumigation (Propylene oxide fumigation for one day) and normal temperature water immersion (25-30°C, 30 minutes), which have different effects of decomposing straw, And then affect the pulp harvest. Its detailed implementation steps are described as follows: using high temperature and high pressure (121 ° C, 15 lb / in 2 , 15 minutes), high-temperature steam (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com