Method for treating sawage generated by preparing carbide slag

A calcium carbide slag slurry and wastewater treatment technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of long treatment time, high treatment cost and high operating cost, To achieve the effect of rapid and thorough response, low processing cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Using ferrous sulfate for precipitation

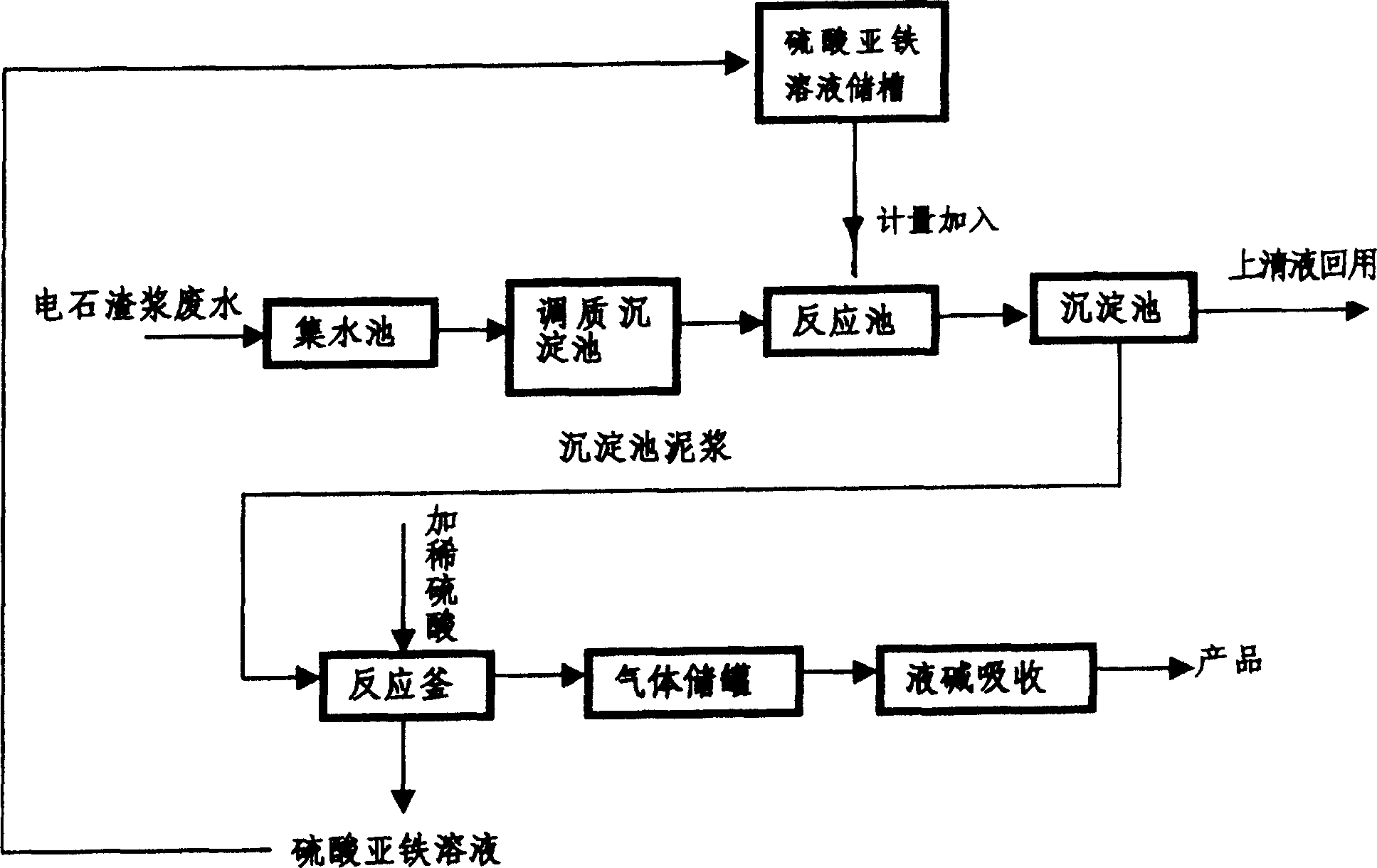

[0037] see figure 1 : The calcium carbide slurry wastewater is collected into the sump, and then sent to the regulating tank to adjust the concentration of pollutants in the wastewater, so that it is basically stable (the concentration of pollutants is not affected by a special production process), so as to be suitable for the technological conditions of the subsequent process. Detect the concentration of sulfide in wastewater.

[0038] Send the wastewater from the adjustment tank into the reaction tank, and add ferrous sulfate (FeSO 4 ) solution, at normal temperature and pressure, the following reaction occurs:

[0039]

[0040] Continue to stir until no black precipitate continues to be produced, the time is about 5 minutes, and the pH value of the water is controlled to 6.7;

[0041] Due to the Ca in wastewater 2+ low enough to form CaSO 4 Precipitation, almost all of which is ferrous sulfide (FeS).

[0...

Embodiment 2

[0058] Example 2 Using Zinc Sulfate Precipitation

[0059] Send the wastewater from the adjustment tank to the reaction tank, and add zinc sulfate (ZnSO 4 ) solution, at normal temperature and pressure, the following reaction occurs:

[0060]

[0061] Continue to stir until no white precipitate continues to be produced, the time is about 5 minutes, and the pH value of the water is controlled to 6.7;

[0062] Send the waste water after the above reaction into the sedimentation tank and let it stand for about 25 minutes to make the sediment settle and separate the solid and liquid. Since zinc sulfide (ZnS) is insoluble in water, it can be separated through natural sedimentation, and the supernatant is sent back The acetylene generation section is recycled or discharged, and the precipitate is sent to a closed reactor;

[0063] Add dilute sulfuric acid (H 2 SO 4 ), at normal temperature and pressure, the following acidolysis reaction occurs with zinc sulfide (ZnS) in t...

Embodiment 3

[0069] Example 3 Use of hydrochloride precipitation

[0070] Send the wastewater from the regulating tank into the reaction tank, and add ferrous chloride (FeCl 2 ) solution, at normal temperature and pressure, the following reaction occurs:

[0071]

[0072] Continue to stir until no black precipitate continues to be produced, the time is about 5 minutes, and the pH value of the water is controlled to be 6.9;

[0073] Send the waste water after the above reaction into the sedimentation tank and let it stand for about 25 minutes to make the sediment settle and separate the solid and liquid. Since ferrous sulfide (FeS) is insoluble in water, it can be separated through natural sedimentation; the supernatant is sent to Back to the acetylene generation section for recycling or discharge, and the precipitate is sent to the closed reactor;

[0074] Add dilute hydrochloric acid (HCl content is 25%) to airtight reactor, under normal temperature, normal pressure, following ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com