Water-soluble corrosion-retarding neutralizer and its preparation process

A water-soluble, corrosion inhibitor technology, applied in the field of corrosion inhibitor neutralizer, can solve the problems of inconvenient operation, poor solubility, low corrosion inhibition efficiency, etc., to reduce the number of maintenance, chemical stability and thermal stability , high corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

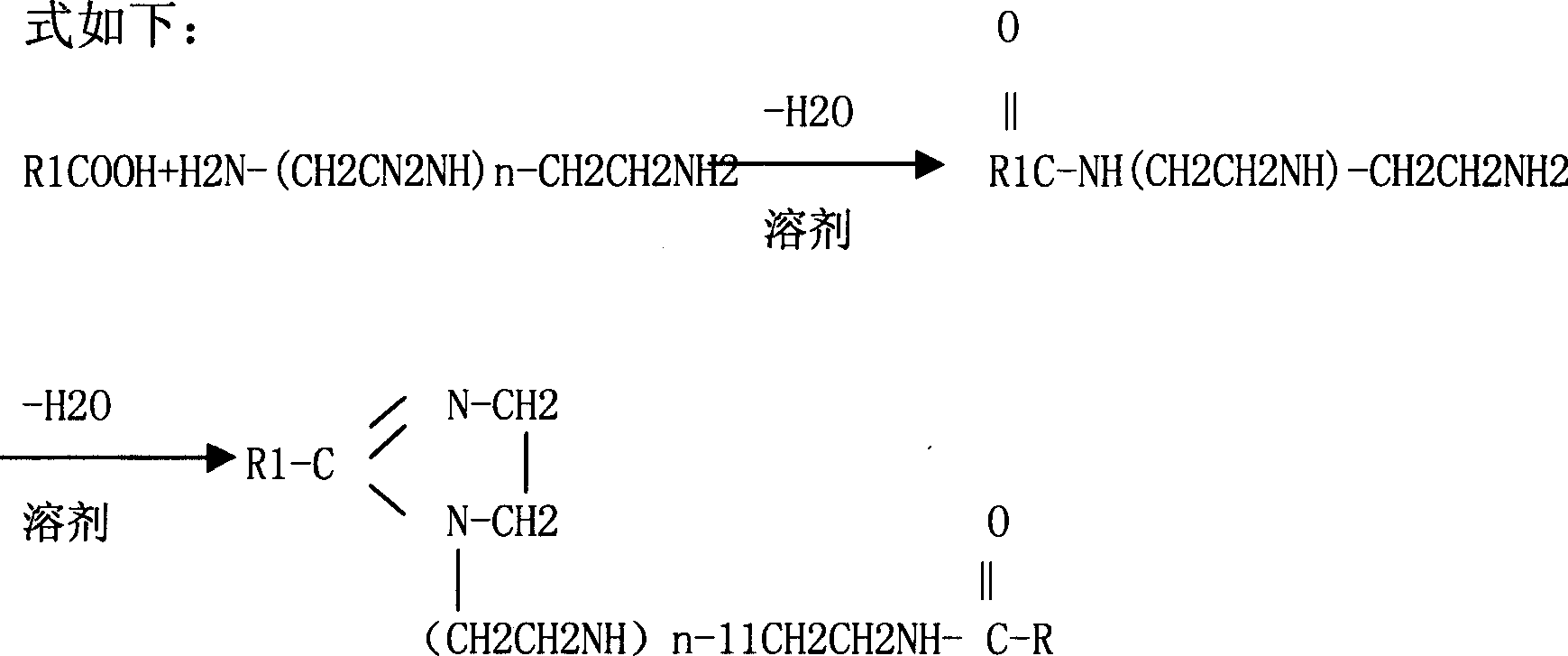

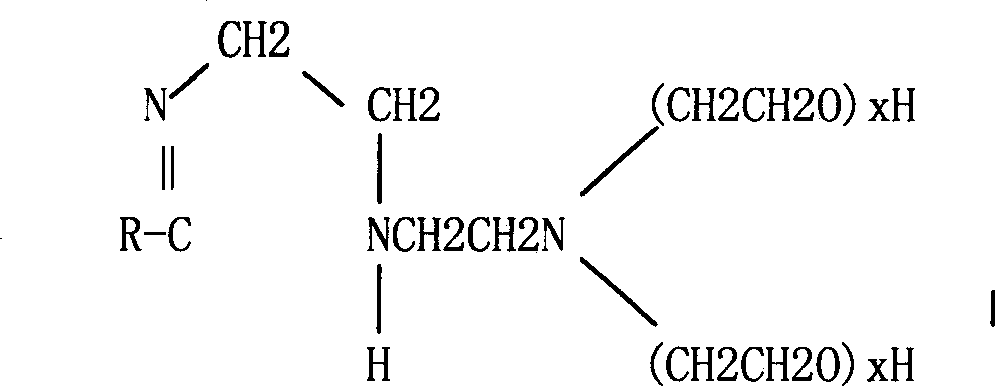

Method used

Image

Examples

Embodiment 1

[0027] 85# naphthenic acid with a crude acid value of 185.4mgKOH / g and diethylenetriamine were put into the reactor at a ratio of 1:1 MOL / MOL, 5% of 120# solvent oil was added, and refluxed at 100°C for 2 hours to obtain A naphthenic acid imidazoline intermediate with an acid value of 2.89 mgKOH / g. Then put the intermediate and ethylene propionic anhydride into the reactor at a molar ratio of 1:0.5, add 5% methanol solvent, react at room temperature for 0.5 hours, and control the reaction temperature not to exceed 80°C to obtain the water-soluble naphthenic acid imidazoline corrosion inhibitor agent. Add 50mg / L of the prepared corrosion inhibitor into the corrosive medium of 1000mg / L HCL+1000mg / L H2S, at 85°C, the corrosion inhibition rate of the A3 steel test piece is 24.75g of the blank sample / m 2 .h down to 0.61g / m 2 .h, the corrosion inhibition efficiency is 97.5%. 10% of the corrosion inhibitor, 10% of the neutralizing agent methylamine, and 80% of methanol solvent w...

Embodiment 2

[0029] The naphthenic acid imidazoline intermediate synthesized according to the conditions of Example 1 was reacted with ethylene oxide at a molar ratio of 1:5 at 120-125° C. for 0.5 hour to obtain the naphthenic acid imidazoline polyoxyethylene corrosion inhibitor. Under the same corrosive medium and corrosion conditions as in Example 1, the corrosion inhibition rate of this product measured is 2.45g / m 2 .h, the corrosion inhibition efficiency is 90.1%. 20% of the corrosion inhibitor, 20% of the neutralizing agent ethylamine, 20% of a 10% NaOH aqueous solution, and 30% of methanol were mixed at 50°C for half an hour to obtain the corrosion inhibitor and neutralizer product. After analysis and testing, its physical and chemical properties all meet the requirements of product quality indicators.

Embodiment 3-12

[0030] Embodiment 3-12 (see Table 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com