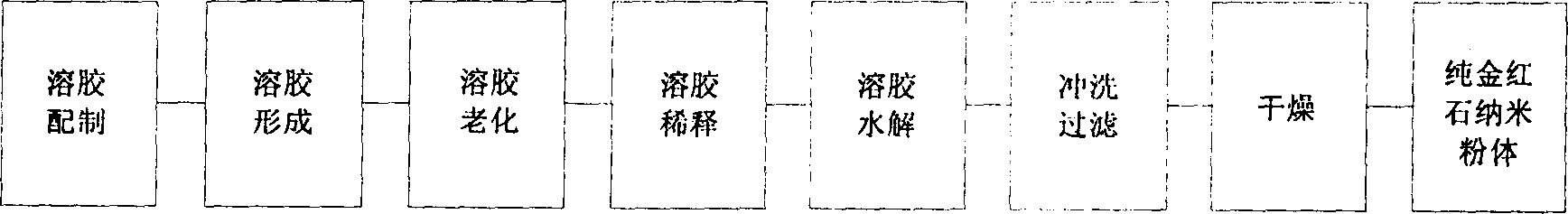

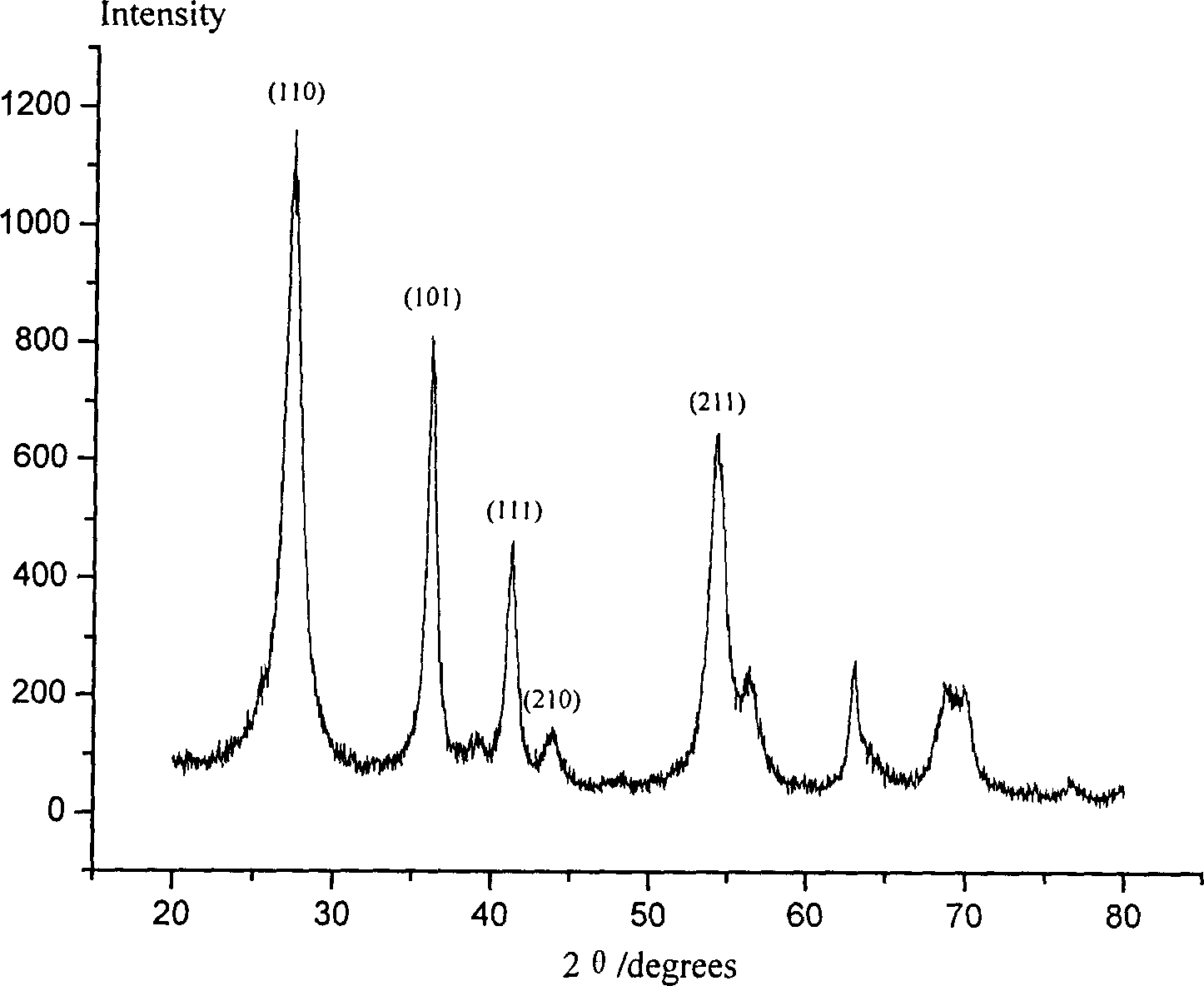

Process for preparing rutile phase titanium dioxide nano-powder

A titanium dioxide and nano-powder technology, applied in the directions of titanium dioxide, nanostructure manufacturing, titanium oxide/hydroxide, etc., can solve the problems of unfavorable industrial production, increase production cost, and high solvent requirements, and achieve easy scale-up experiments and low cost. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Fix a three-neck bottle with a capacity of 500mL in an ice-water bath, take pure water (H 2 (2) 200mL is packed in the there-necked bottle; A condenser is installed on the middle port of the there-necked bottle, and utilizes tap water to condense; A junction thermometer is installed on a mouth of the there-necked bottle, to monitor and control the temperature of the reaction system; Take TiCl 4 Put 100mL into a dry constant-pressure separating funnel, and install the constant-pressure separating funnel on the other side port of the three-necked flask; under the condition of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, The titanium chloride solution is slowly dropped into pure water, and the temperature of the entire dropping and mixing process is controlled at about 20°C by controlling the dropping speed and the temperature of the ice-water bath; with the addition of titanium tetrachloride, the color of ...

Embodiment 2

[0041] (1) adopt the device described in step (1) in embodiment 1, get pure water (H 2 (2) 300mL is packed into there-necked bottle; Get TiCl 4 Put 100mL into a dry constant-pressure separating funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, slowly drop the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath keeps the temperature of the entire dropping and mixing process at about 5°C; after the addition of titanium tetrachloride is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it ;

[0042] (2) adopt the device described in step (2) in embodiment 1, after titanium tetrachloride aqueous sol is placed 50 hours, get 100mL above-mentioned sol and pack in the there-necked bottle of 500mL; Take H 2 Put 0300mL into a dry constant-...

Embodiment 3

[0046] (1) adopt the device described in step (1) in embodiment 1, get pure water (H 2 (2) 100mL is packed into there-necked bottle; Get TiCl 4 Put 100mL into a dry constant-pressure separating funnel; under the conditions of magnetic stirring and ice-water bath cooling, turn on the switch of the constant-pressure separating funnel, slowly drop the titanium tetrachloride solution into pure water, and control the dropping speed and The temperature of the ice-water bath keeps the temperature of the entire dropping and mixing process at about 30°C; after the addition of titanium tetrachloride is completed, continue to stir for 2 hours. At this time, the mixed system is a light yellow-green sol. Cool it to room temperature and place it ;

[0047] (2) adopt the device described in step (2) in embodiment 1, after titanium tetrachloride aqueous sol is placed 30 hours, get 100mL above-mentioned sol and pack in the there-necked bottle of 500mL; Take H 2 Put 0350mL into a dry constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com