Multi-phase catalyst reaction method, and reaction equipment therefor

A multiphase reaction and catalyst technology, which is applied in the direction of organic chemical methods, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of increasing side reactions, accelerating the polymerization of raw materials and products, and difficult operation, so as to prevent side reactions And the effect of polymerization, separation, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0187] The formation reaction of methyl acrylate was carried out using a fixed bed reactor.

[0188] Product: methyl acrylate

[0189] Raw materials: acrylic acid, methanol

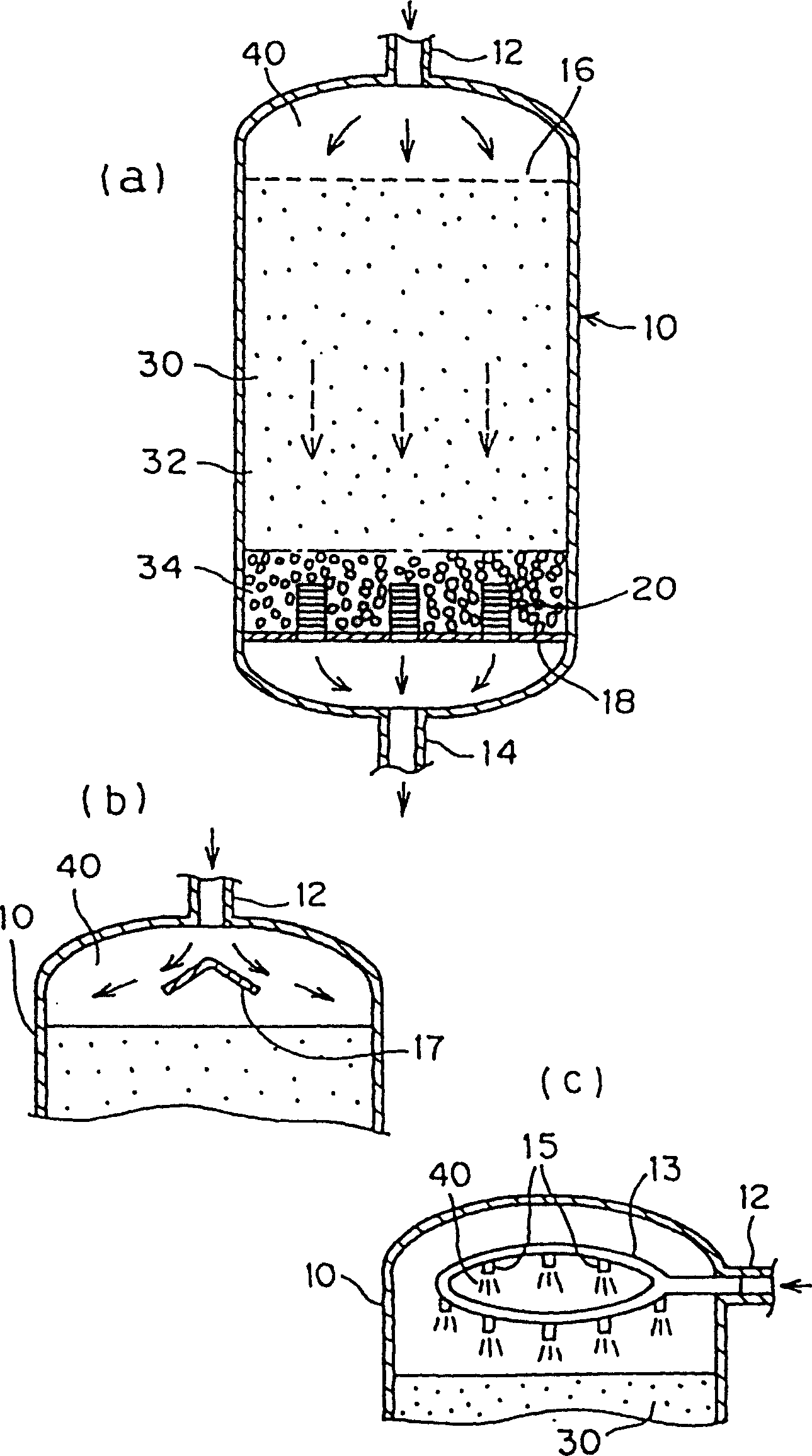

[0190] Reactor: fixed bed reactor (refer to figure 1 ), a diameter of 1400mm, a height of 2300mm, and a capacity of 3.5m in the straight barrel 3 , resin installation volume 2.0m 3 .

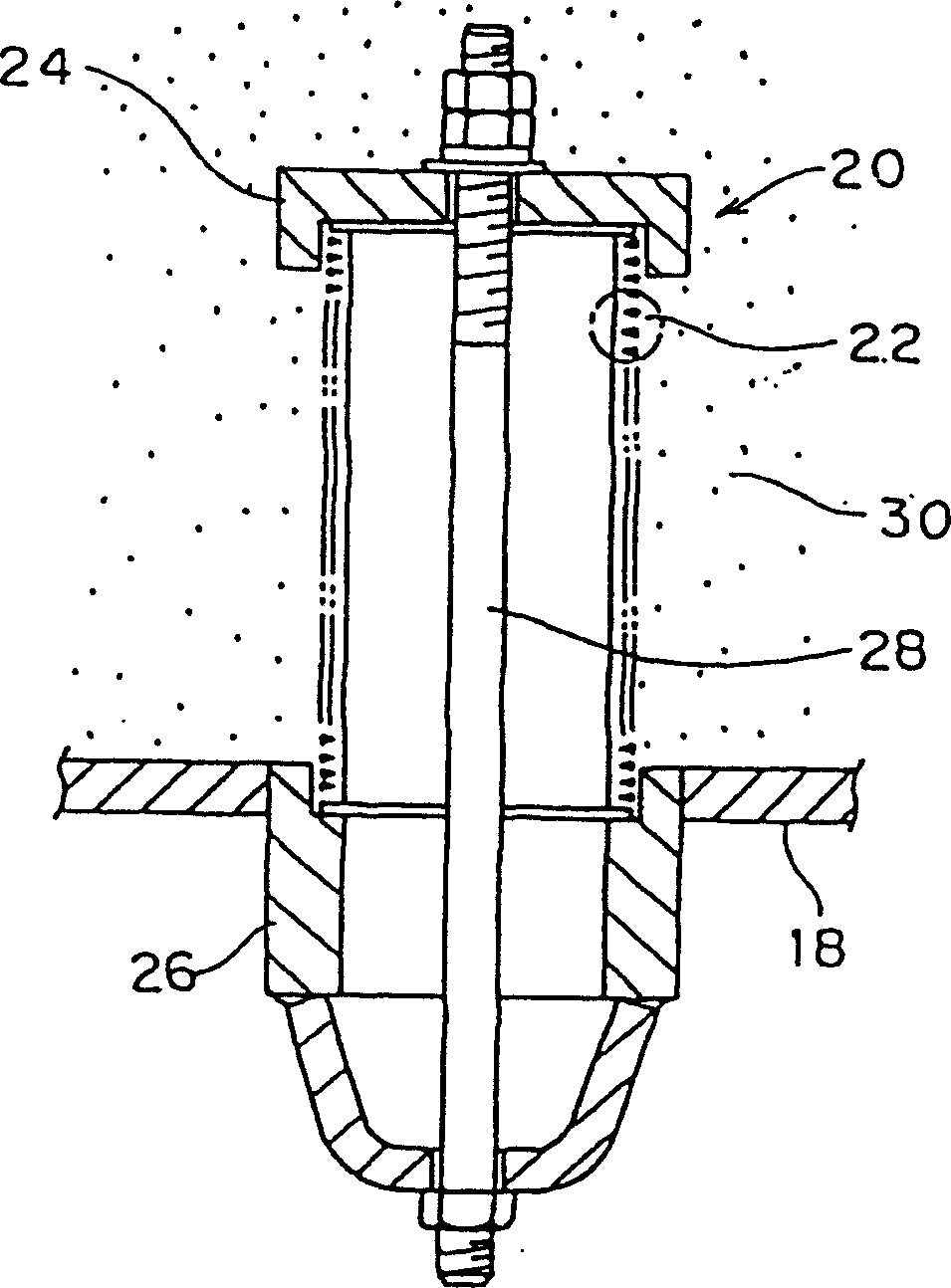

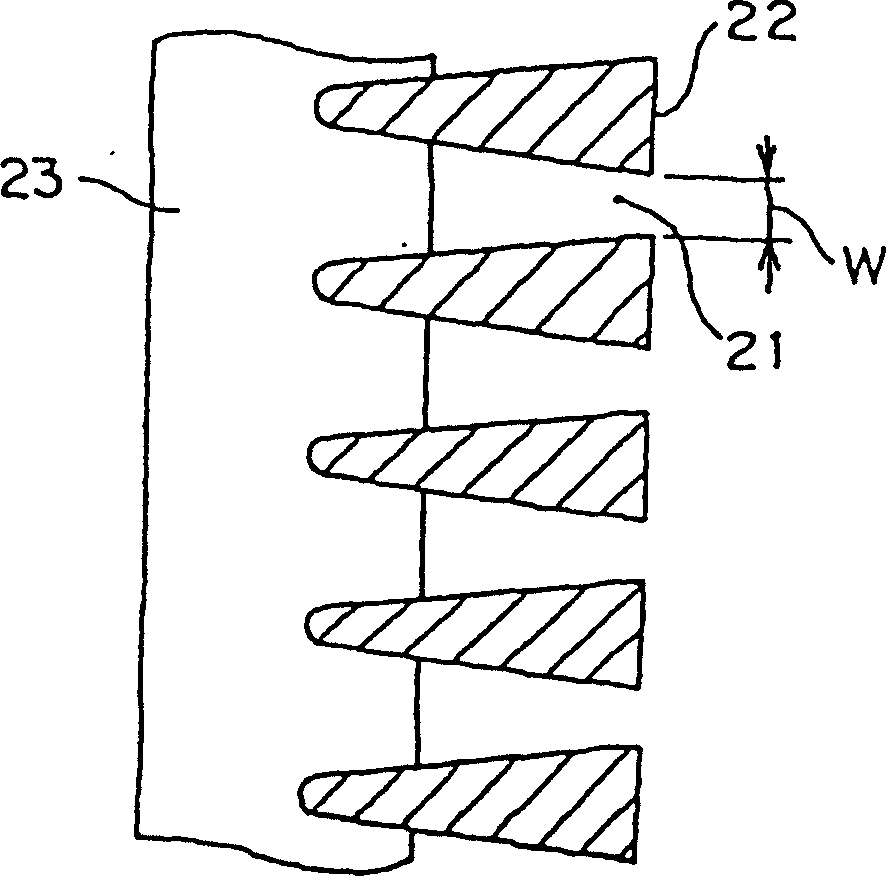

[0191] Solid-liquid separator: Johnson screen (trade name, sold by JGC Yunibasaru Co., Ltd.), cylindrical type, and the effective filtering part (linear screen) is arranged at a position 10mm lower than the partition plate (refer to figure 2 ), the outer diameter of the cylindrical screen is 50mm, the effective length is 170mm, the wire width is 1.5mm, the gap width is 0.3mm, and the number of settings is 20 (13.0 pieces / m 2 ), the effective filter area is 0.534m 2 (0.027m 2 / piece), opening area 0.089m 2 (0.0044m 2 / indivual).

[0192] Flowing liquid volume: Flowing liquid volume 1.67m 3 / hour, liquid density ...

Embodiment 2

[0201] In Example 1, the part where the linear screen was arranged protruded 15 mm from the upper surface of the partition plate, and this structure was used as the Johnson screen of the solid-liquid separator. The structure in which the gap between the lower end of the linear screen and the surface of the partition plate is left open, and the upper surface of the partition plate slightly retains the reaction liquid.

[0202] -Implementation results-

[0203] After the reaction was carried out for 1000 hours, the polymer was attached to the supporting structure of the wire mesh. Half of the wire is slightly clogged. However, it can be removed after spray cleaning. A part of the wire is cleaned with a brush.

Embodiment 3

[0205] The formation reaction of methyl methacrylate was carried out. The same conditions as in Example 1 are not described again.

[0206] Product: methyl methacrylate

[0207] Original: methacrylic acid, methanol

[0208] Reactor: fixed bed reactor (refer to figure 1 ), with a diameter of 1800mm and a height of 2500mm, used in a liquid-filled state.

[0209] Solid-liquid separator: Johnson screen (trade name, sold by Nikki Yunibasaru Co., Ltd.), the outer diameter of the cylindrical screen is 60mm, the effective length is 170mm, the wire member is 1.5mm wide, the gap is 0.15mm wide, and the number of installations is 20 (4.8 piece / m 2 ), the effective filter area is 0.64m 2 (0.032m 2 / piece), opening area 0.058m 2 (0.0029m 2 / indivual).

[0210] Flowing liquid volume: Flowing liquid volume 3.00m 3 / h, liquid density 900kg / m 3 , The effective filter area flows through the speed of 1.30mm / s, and the opening part flows through the linear speed of 14mm / s.

[0211] H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com