Tail car connecting and separating device and connecting and separating method of stacker-reclaimer

The technology of a separation device and separation method, which is applied in the field of stacker-reclaimers, can solve problems such as time-consuming, reduced operating efficiency, and collisions, and achieve the effect of avoiding collision accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

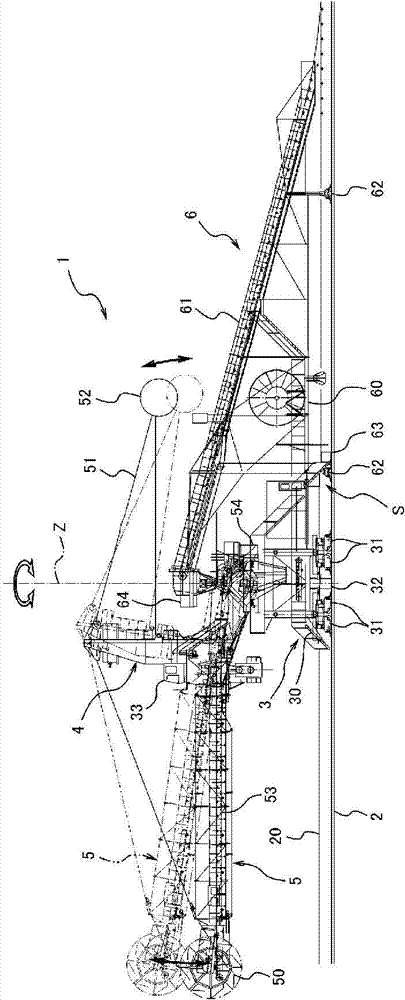

[0045] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings. figure 1 It is an overall structural diagram of a stacker-reclaimer 1 according to an embodiment, and as an example, the stacker-reclaimer 1 is used as an accumulation of coal (bulk materials) carried by a conveyor on a coal raw material stockyard in an ironworks. Handling), and the stacker-reclaimer of the reclaimer that continuously takes out and sends out the full coal.

[0046] -the whole frame-

[0047] The basic structure of the stacker-reclaimer 1 according to the present embodiment is known in the past, and is equipped with figure 1 The walking beam 3 (traveling body) that reciprocates on a pair of rails 2 laid along the coal raw material stockyard extending left and right. In addition, for convenience of description, the direction in which the rail 2 extends is referred to as the front-rear direction, and figure 1 The left side is called the front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com