Asbestos-free high-purity natural flaky mineral and process for production thereof

A manufacturing method, asbestos-free technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as unavailability, and achieve the effect of improving yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

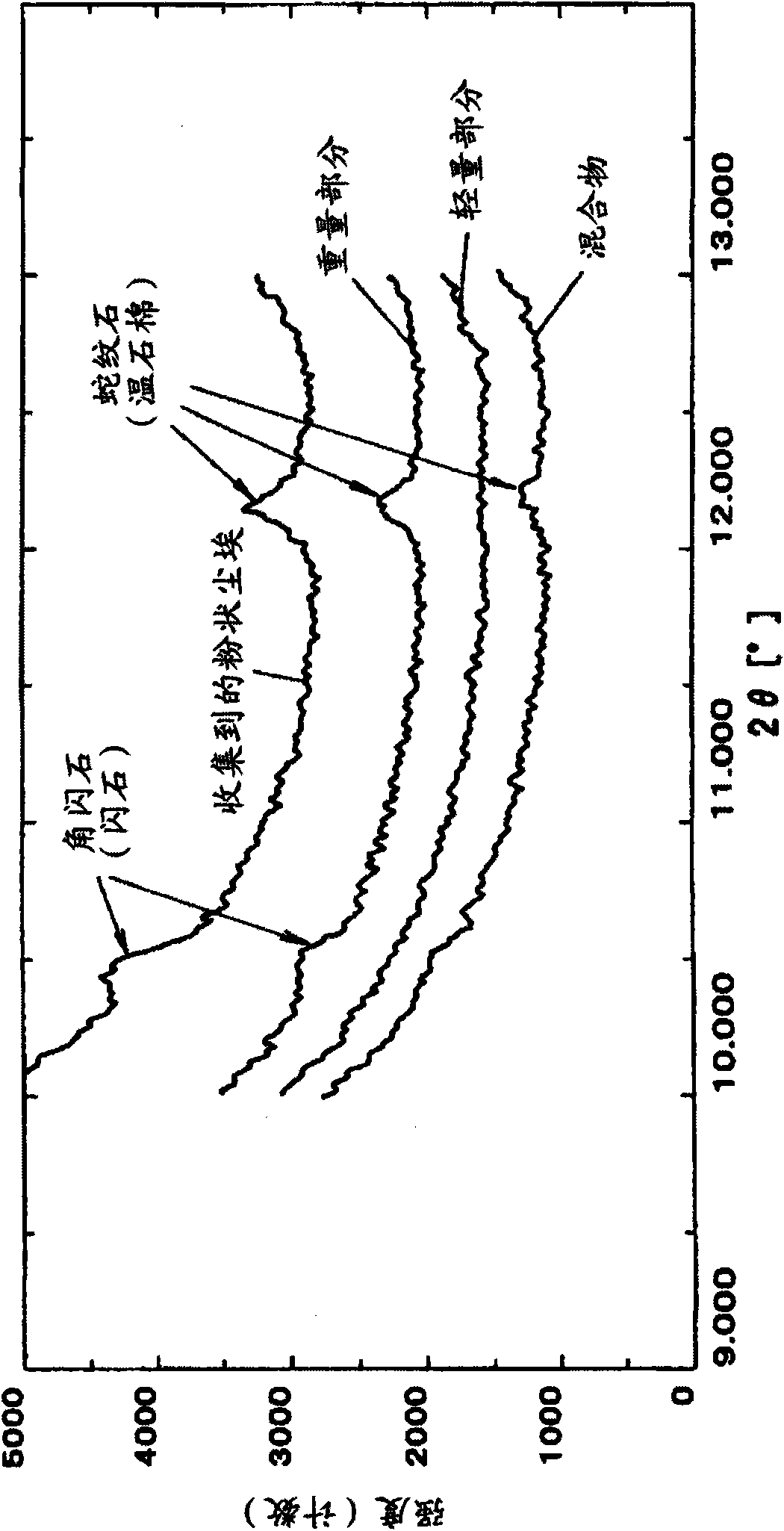

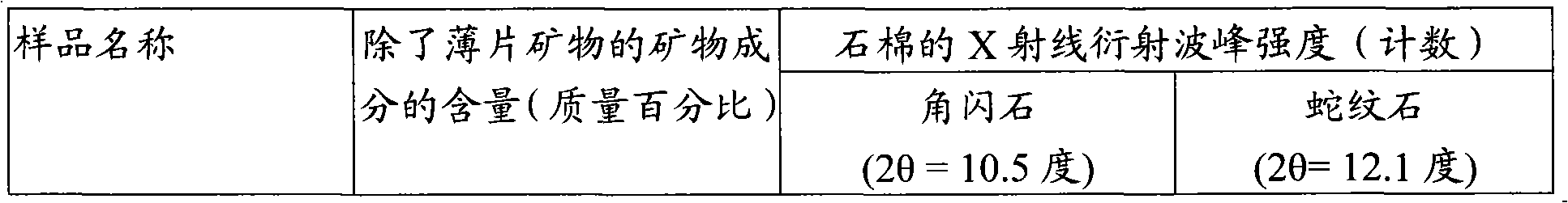

[0061] Natural flake mineral ore (lump) contains hydromica and vermiculite (flake mineral) as main components and also contains hornblende and serpentine as mineral components other than the flake mineral, each containing pyroxene, quartz and The asbestos component of feldspar, while the natural flake mineral ore is coarsely crushed using a roller crusher. Subsequently, most of the mineral components except the flake minerals are removed by airflow classification to prepare a first mixture, and the first mixture is sieved to prepare a second mixture having a controlled particle size of 0.5 mm to 1 mm. Two mixtures.

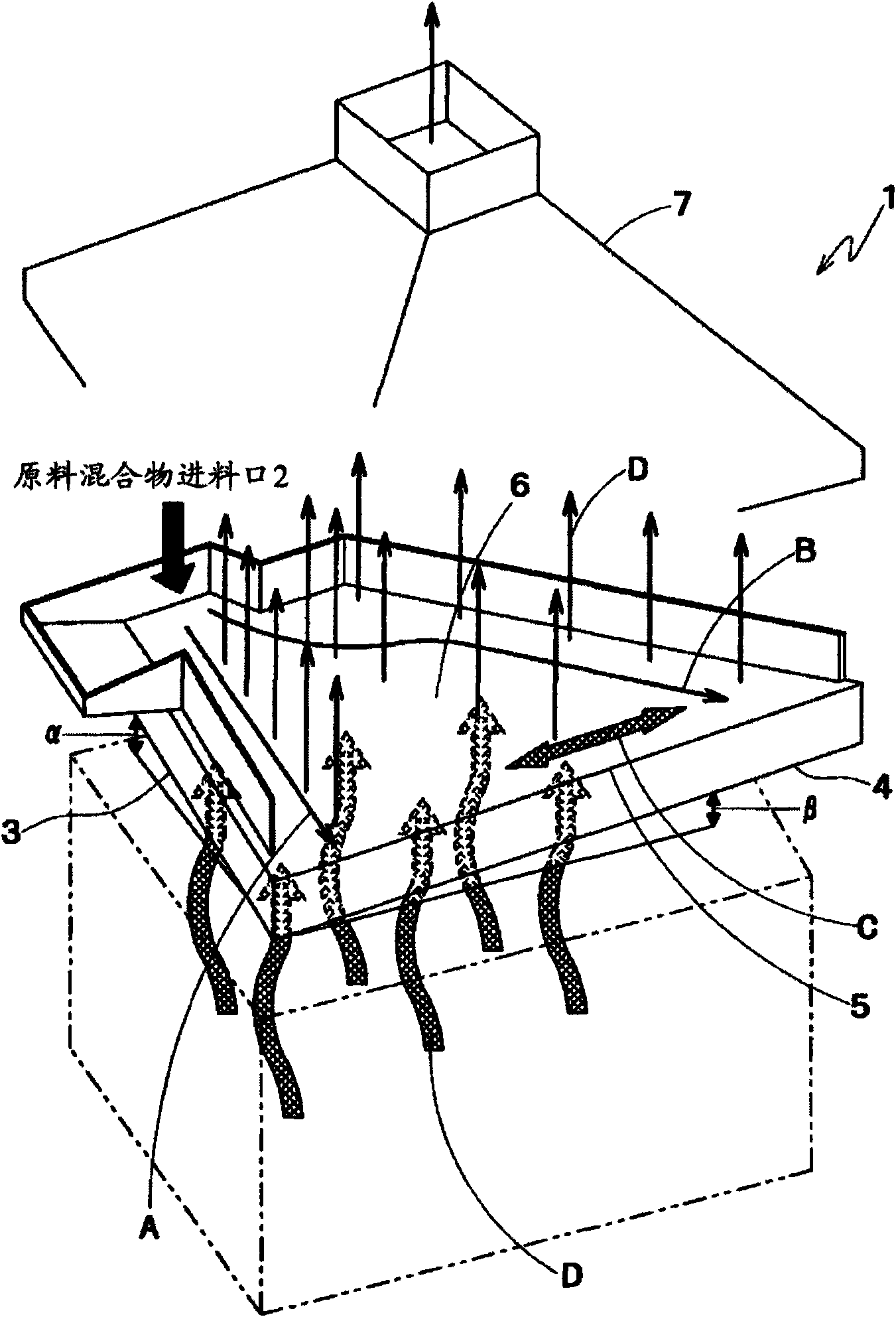

[0062]The second mixture having a controlled particle size of 0.5 mm to 1 mm is fed to the figure 1 In the said pneumatic table (type: V-135; product of Nitto Denko Co., Ltd.). In the following cases, sheet material receiving strong air resistance (hereinafter simply referred to as light weight portion) is collected from the light side A of the outlet 5, and bul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com