Method for preparing nano- copper powder by chemical reduction in water solution

A technology of nano-copper powder and reduction method is applied in the field of copper powder preparation, which can solve the problems of limiting the use effect of copper powder and the like, and achieve the effects of high powder preparation efficiency, low price and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Adopt the method of the present invention to prepare nano-copper powder

[0019] The preparation steps are as follows:

[0020] (a) Mix the following materials according to the formula.

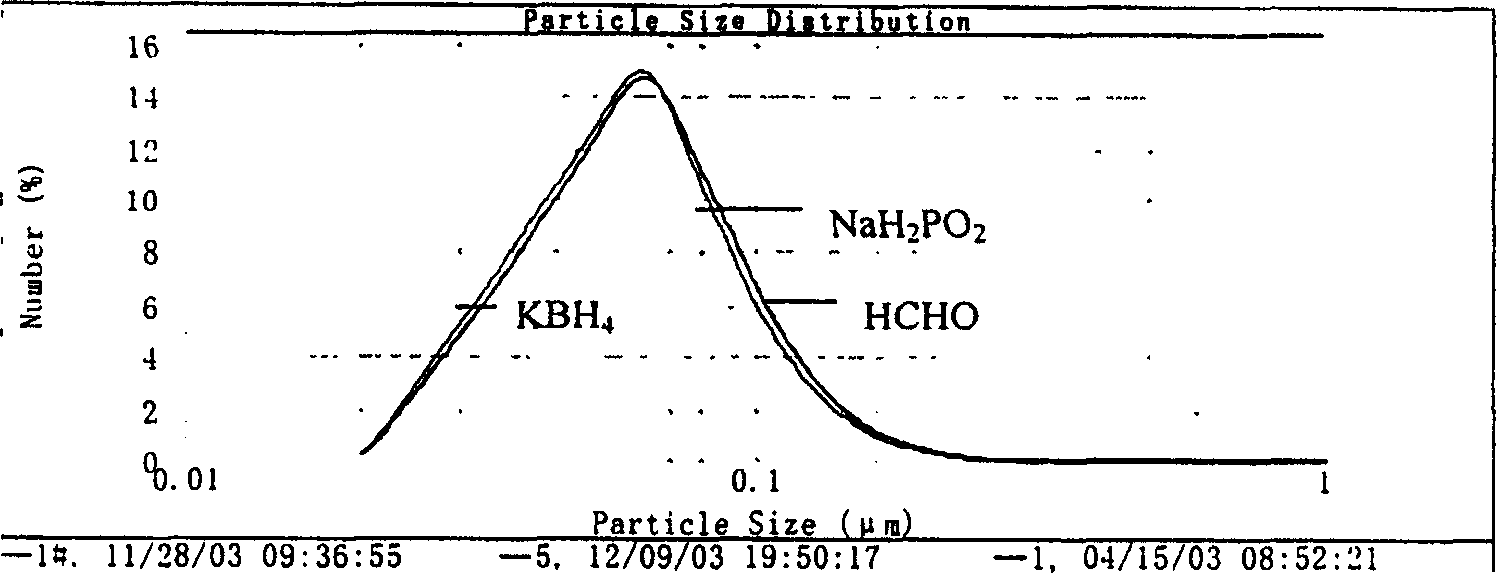

[0022] Formaldehyde 300g / L

[0023] Silver nitrate 5mg / L

[0024] Gelatin 25g / L

[0025] Potassium Sodium Tartrate 15g / L

[0026] Sodium hydroxide 45g / L

[0027] (b) Heat the homogeneously mixed material to 80°C.

[0028] (c) Apply an ultrasonic field of 800W in the reactor to react to generate nano-copper powder.

[0029] (d) Cool the reacted complete material to room temperature.

[0030] (e) separating the nano-copper powder in the material from the solution.

[0031] (f) drying the nano-copper powder under the protection of an inert gas.

Embodiment 2

[0032] Embodiment 2: Adopt the method of the present invention to prepare nano-copper powder

[0033] The preparation steps are as follows:

[0034] (a) Mix the following materials according to the formula.

[0035] Copper chloride 45g / L

[0036] Sodium hypophosphite 20g / L

[0037] Palladium chloride 10mg / L

[0038] Sodium dodecylbenzenesulfonate 30g / L

[0039] Triethanolamine 25g / L

[0040] Potassium hydroxide 30g / L

[0041] (b) Heat the homogeneously mixed material to 75°C.

[0042] (c) Apply an ultrasonic field of 700W in the reactor to react to generate nano-copper powder.

[0043] (d) Cool the reacted complete material to room temperature.

[0044] (e) separating the nano-copper powder in the material from the solution.

[0045] (f) drying the nano-copper powder under the protection of an inert gas.

Embodiment 3

[0046] Embodiment 3: Adopt the method of the present invention to prepare nano-copper powder

[0047] The preparation steps are as follows:

[0048] (a) Mix the following materials according to the formula.

[0050] Potassium borohydride 25g / L

[0051] Silver nitrate 2mg / L

[0052] Gelatin 30g / L

[0053] Triethanolamine 28g / L

[0054] Sodium hydroxide 37g / L

[0055] (b) Heat the homogeneously mixed material to 70°C.

[0056] (c) Apply an ultrasonic field of 750W in the reactor to react to generate nano-copper powder.

[0057] (d) Cool the reacted complete material to room temperature.

[0058] (e) separating the nano-copper powder in the material from the solution.

[0059] (f) drying the nano-copper powder under the protection of an inert gas.

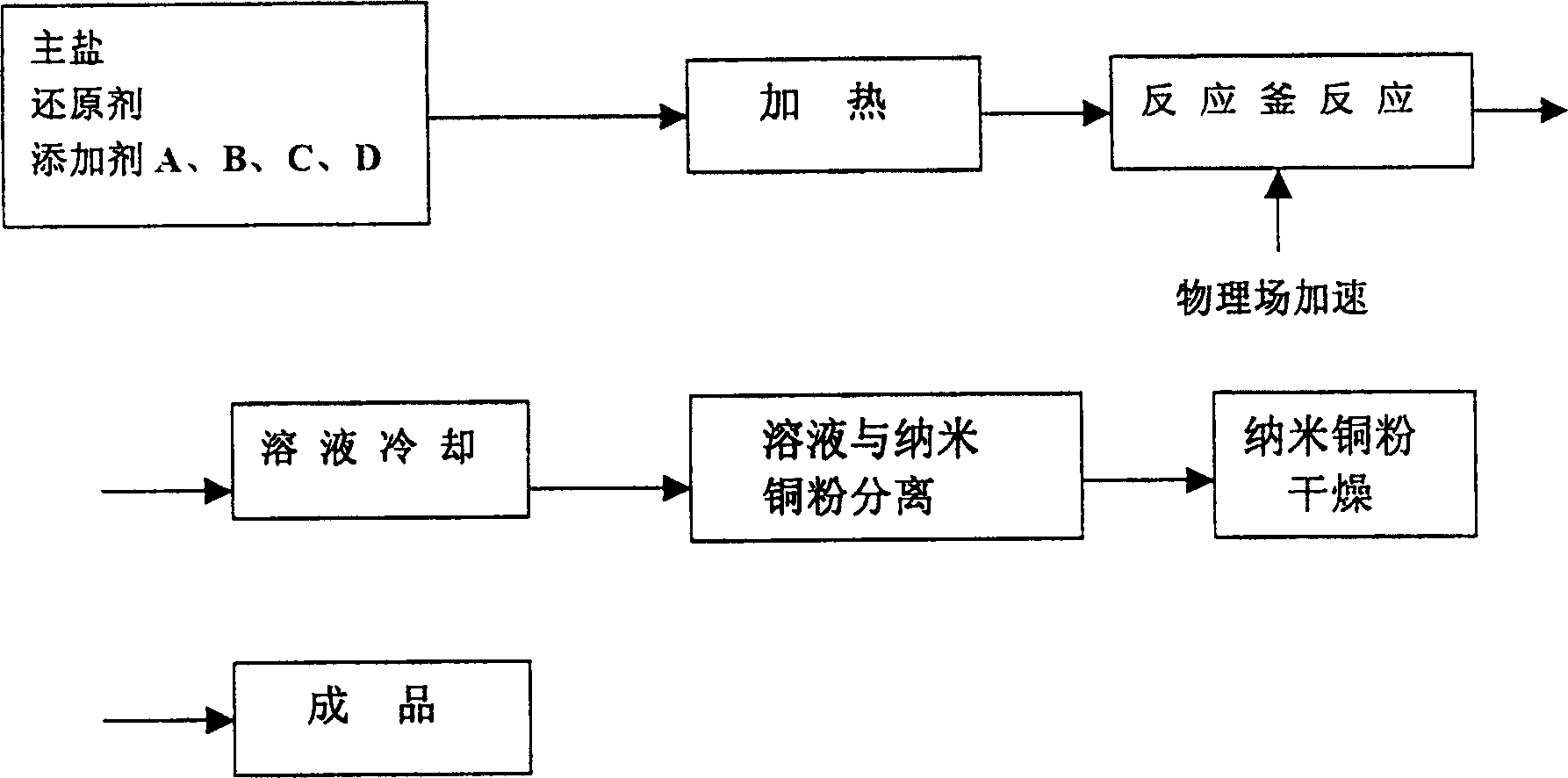

[0060] Adopt above-mentioned embodiment, equipment investment is little, process is simple, preparation cost is low, and process sees figure 1 . The nano-copper powder obtained by this method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com