Thermistor heating installation

A thermistor and heating device technology, applied in the field of electric heaters, can solve the problems of human body feeling uncomfortable, poor overall comfort, uneven heat dissipation, etc., achieve uniform temperature rise, high thermal efficiency, and save money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

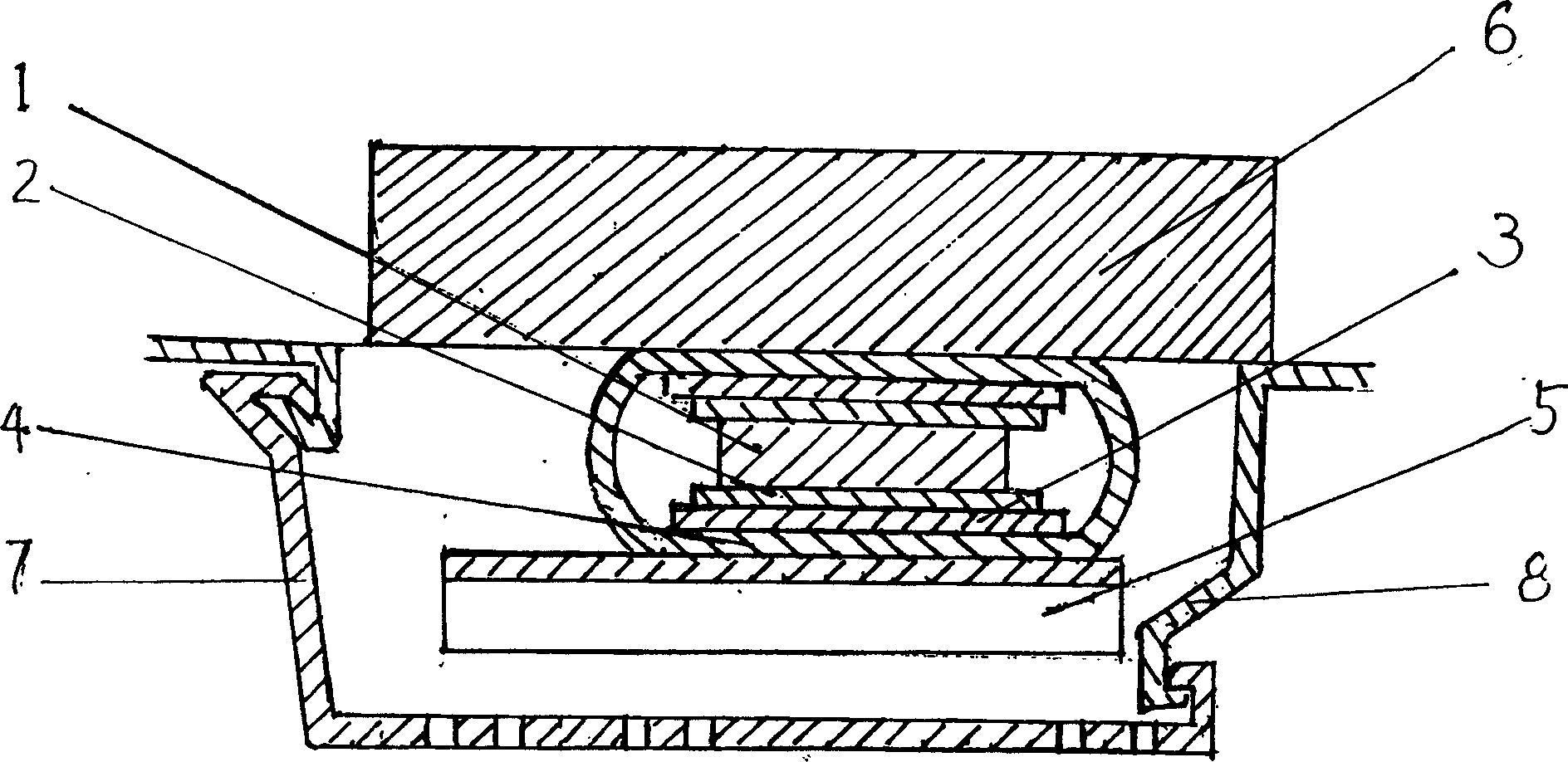

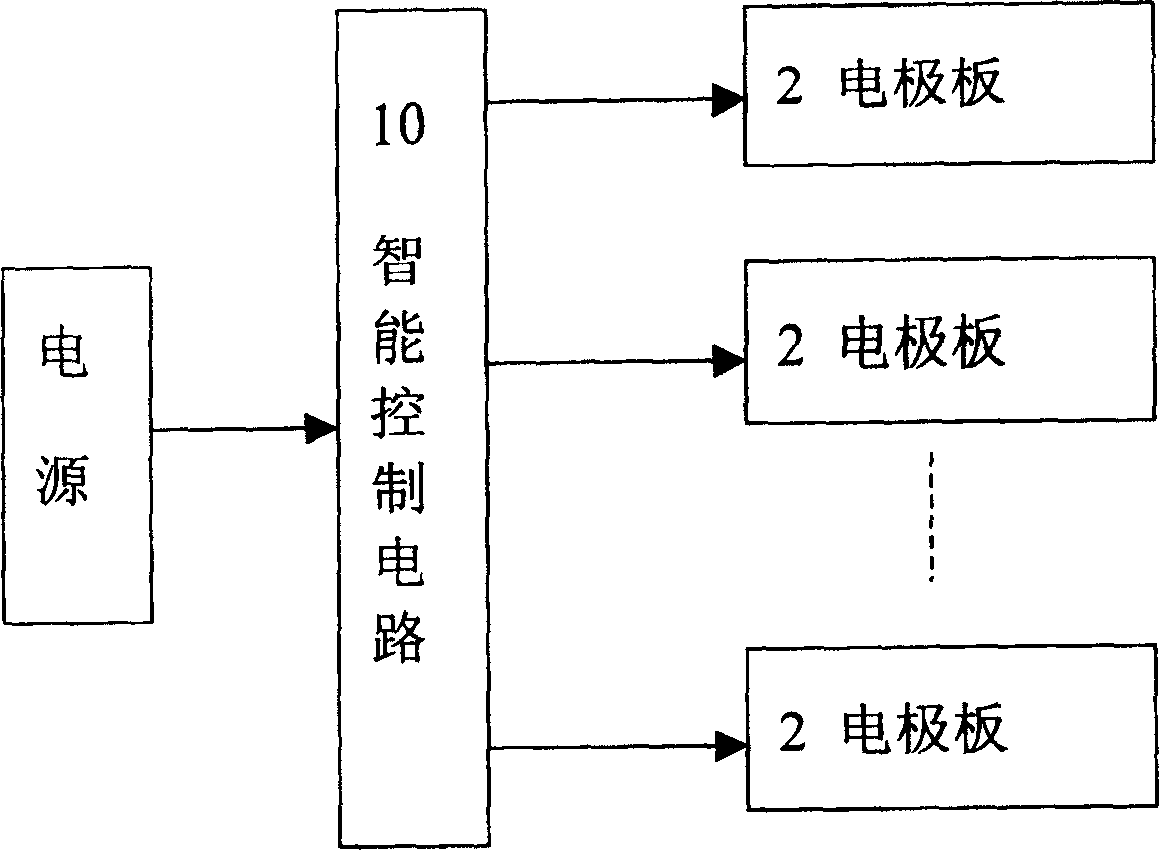

[0014] In order to implement the present invention, the thermistor sheet adopts a positive temperature coefficient thermistor (PTCR), which is made of electronic ceramics. Both sides of the thermistor 1 are connected to the electrode plate 2, and the electrode plate 2 is connected to the intelligent control circuit. The electrode plate 2 is generally made of aluminum plate. In order to reduce the contact resistance, the electrode plate and the thermistor are tightly pressed together. And glue it with conductive glue. In order to prevent leakage, there is an insulating layer 3 outside the electrode plate 2. The insulating layer 3 is generally made of alumina material, and the insulating layer 3 is packaged with a metal sealing tube 4. The metal sealing tube 4 is generally made of aluminum or aluminum alloy plate, flat and round The sealing tube is tightly pressed on the insulating layer 3, on the one hand, the connection between the inner electrode plate 2 and the thermistor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com