Process for preparing nano gold particle materal

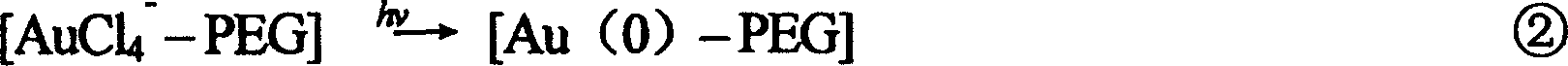

A nano-gold and particle technology, which is applied in the field of preparation of nano-gold particle materials, can solve problems such as environmental pollution of cyanide reagents, and achieve the effects of reducing production costs, improving size distribution and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Get 2ml of HAuCl containing Au(III) 600mg / L 4 Solution (gold concentration 48mg / L), after diluting with water, add 0.846g of PEG600 (or 0.564g of PEG400, or 2.82g of PEG2000, or 8.46g of PEG6000;), 1ml of acetone (PEG400:Au=480:1, PEG600:Au=720 :1, PEG2000:Au=2400:1, PEG6000:Au=7200:1, acetone:Au=637:1), dilute to 25ml with water, and mix well. where HAuCl 4 The concentration is 2.44×10 -4 mol / L, PEG600 (or PEG400, or PEG2000, or PEG6000) concentration is 5.64×10 -2 mol / L, (CH 3 ) 2 The CO concentration is 0.53mol / L. The mixture solution is transferred to a quartz reactor, and irradiated with 300nm (48W) ultraviolet light for 15min under an Ultra-LUM (PATENT 5434478) ultraviolet lamp until the surface plasmon resonance spectrum λ of the solution system gold particles max Absorbance no longer changes. After characterization by TEM, the average diameter of the gold particles is about 5 nm (5 nm when using PEG400, 4 nm when using PEG2000, and 3 nm when...

Embodiment 2

[0026] Embodiment 2: Get 2ml of HAuCl containing Au(III) 600mg / L 4 After diluting the solution with water, add PEG6000.846g (or PEG400 0.564g; PEG2000 2.82g; PEG6000 8.46g), 1ml acetone, dilute to 25ml with water, and mix well. where HAuCl 4 The concentration is 2.44×10 -4 mol / L, PEG600 (or PEG400, or PEG2000, or PEG6000) concentration is 5.64×10 -2 mol / L, (CH 3 ) 2 The CO concentration is 0.53mol / L. The mixture solution is transferred to the quartz reactor and 2ml is taken out, and the gold "seed crystal" colloid solution prepared by the corresponding protective agent system in 2ml of Example 1 is added to the mixture simultaneously, and then the quartz reactor is placed in the Ultra-LUM (PATENT5434478) ultraviolet Irradiate at 300nm (48W) for 15min under the lamp, or irradiate for 50min under the plateau ultraviolet sunlight, until the surface plasmon resonance spectrum λ of the gold particles in the solution system max Absorbance no longer changes. After TEM characteri...

Embodiment 3

[0027] Embodiment 3: get 2ml to contain the HAuCl of Au(III) 600mg / L 4 Dilute the solution with water, adjust the volume to 25ml with water, heat to boiling on an electric stove, add 18 mg of trisodium citrate while stirring, continue stirring and keep boiling for 5 minutes, cool to obtain a gold colloid solution and use it as a "seed crystal" . In addition, take 2ml of HAuCl containing Au(III) 600mg / L 4 After diluting the solution with water, add 0.846g of PEG600, 1ml of acetone, dilute to 25ml with water, and mix well. where HAuCl 4 Concentration 2.44×10 -4 mol / L, PEG600 concentration 5.64×10 -2 mol / L, (CH 3 ) 2 The CO concentration is 0.53mol / L. Transfer the mixture solution to a quartz reactor and take out 2ml, then add 2ml of the "seed crystal" solution prepared by the above-mentioned chemical method, and then irradiate the quartz reactor at 300nm (48W) for 15min under the Ultra-LUM (PATENT 5434478) ultraviolet lamp , or irradiate for 50 minutes under the plateau ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com