Graft polymer, wood-plastic material containing same and its preparing method

A technology for grafting polymers and wood-plastic materials, applied in the field of dual-feature composite materials, can solve the problems of reducing the moisture absorption and polarity of wood powder, affecting material properties, poor material properties, etc. Performance, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

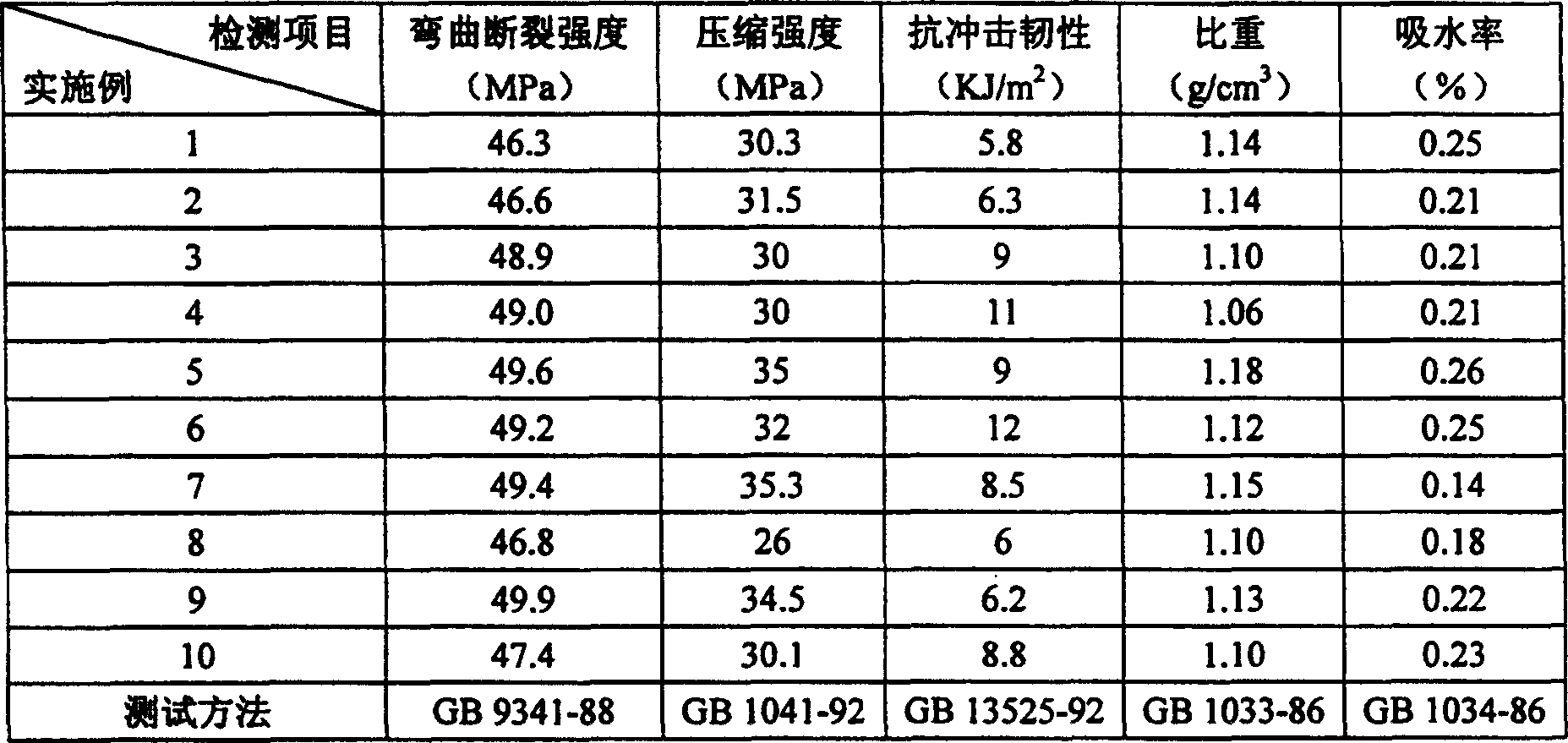

Examples

Embodiment 1

[0041] Graft polymer formulation:

[0042] Raw material formula Proportion

[0043] Polyethylene (LDPE 1F7B) 100

[0044] Vinyltrimethoxysilane 2

[0045] Di-tert-butyl peroxide 0.02

[0046] Preparation process: Mix all components in the formula evenly according to the formula ratio, and then extrude into strips in an extruder at a temperature of 150°C to 170°C. The modified base material, the graft polymer of the present invention, is obtained by pelletizing, with a melt index of 1.5 g / 10 min.

[0047] The formula of wood-plastic material:

[0048] Raw material formula : Proportion

[0049] Graft polymer 40

[0050] Polyethylene (HDPE 5000S) 20

[0051] Vegetable fiber powder 40

[0052] Antioxidant 1010 0.1

[0053] Polyethylene wax 3

[0054] Catalyst cobalt naphthenate 0.2

[0055] Preparation process: mix the components in the above formula, put them into an extruder, extrude at a temperature of 160°C to 180°C, and extrude and plasticize to obtain the ...

Embodiment 2

[0057] Graft polymer formulation:

[0058] Raw material formula : Proportion

[0059] Polyethylene (LDPE 2F2B) 100

[0060] Vinylmethyldimethoxysilane 3

[0061] Di-tert-butyl peroxide 0.2

[0062] Preparation process: Mix all components in the formula evenly according to the formula ratio, and then extrude into strips in an extruder at a temperature of 150°C to 185°C. After pelletizing, the modified base material—the graft polymer of the present invention is obtained, with a melt index of 0.8 g / 10 min.

[0063] The formula of wood-plastic material:

[0064] Raw material formula : Proportion

[0065] Graft polymer 40

[0066] Polyethylene (HDPE 50008) 10

[0067] Vegetable fiber powder 50

[0068] Antioxidant 1010 0.15

[0069] Antioxidant 168 0.15

[0070] Liquid paraffin 1.5

[0071] Catalyst tetrabutyl titanate 0.2

[0072] Preparation process: mix the components in the above formula, put them into an extruder, extrude at a temperature between 150°C and ...

Embodiment 3

[0074] Graft polymer formulation:

[0075] Raw material formula : Proportion

[0076] Polyethylene (LDPE 1I2A) 100

[0077] Vinyltriethoxysilane 2

[0078] Dicumyl peroxide 0.1

[0079] Preparation process: Mix the components in the formula evenly according to the proportion of the formula, and then extrude into strips in the extruder, and the extrusion temperature is 190°C to 210°C. Pelletizing to obtain the modified material—the graft polymer of the present invention, with a melt index of 1.0 g / 10 min.

[0080] The formula of wood-plastic material:

[0081] Raw material formula : Proportion

[0082] Graft polymer 20

[0083] Polyethylene (LLDPE103AA) 30

[0084] Vegetable fiber powder 50

[0086] Paraffin 5

[0087] Antioxidant 1076 0.2

[0088] Catalyst dibutyltin dilaurate 0.3

[0089]Preparation process: Mix all the components in the above formula evenly, put them into an extruder and extrude at a temperature of 150°C to 190...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com