Vertical pulverizing and drying device

A vertical and grinding technology, applied in the field of vertical grinding and drying devices, can solve the problems of clogging of grinding rollers, unable to solve the content of carbide slag, etc., and achieve the effect of ensuring discharge that meets the standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

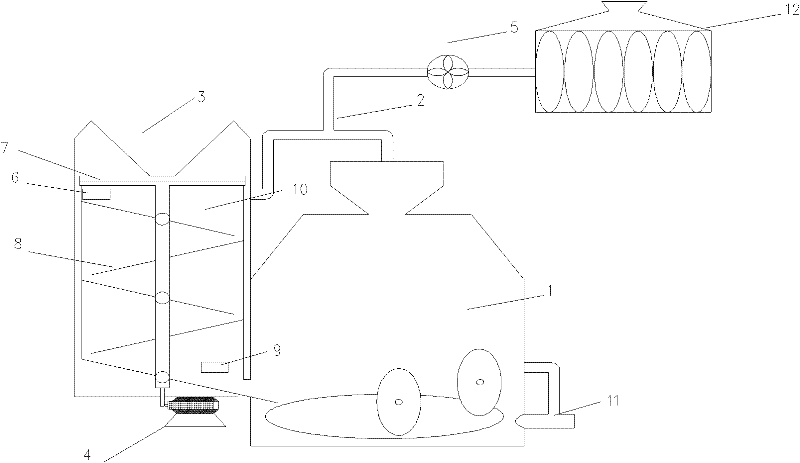

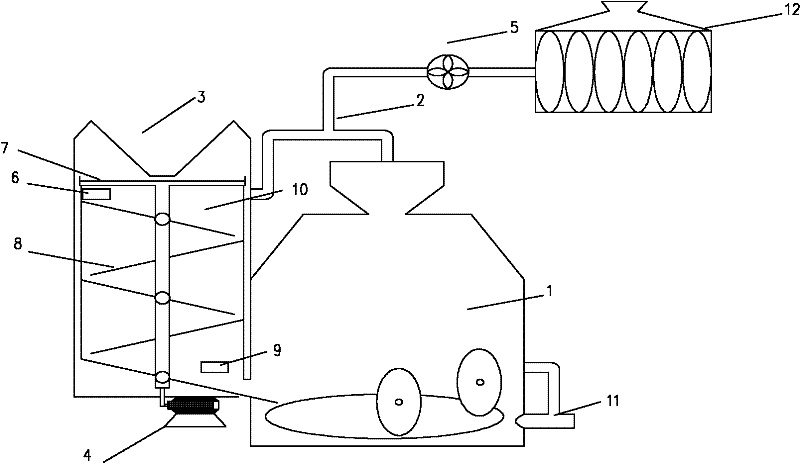

[0020] Such as figure 1 , 2 The vertical drying and grinding device shown includes a raw material pre-drying system and a raw material grinding device 1 , and the raw material pre-drying system includes a flue gas duct, a sloping plate feed box and an oscillating device 4 .

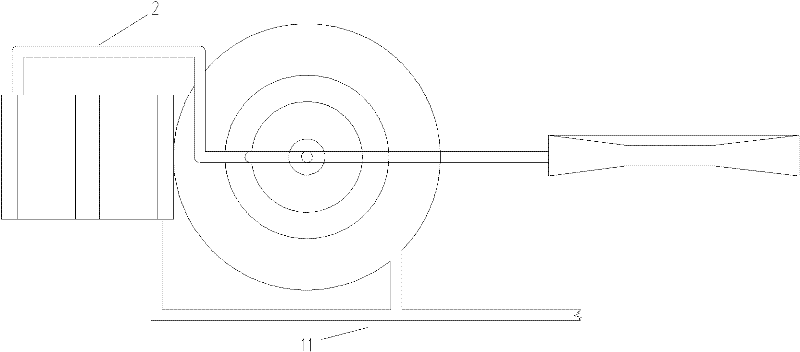

[0021] The flue gas duct includes: a flue gas introduction pipeline 11, a flue gas export pipeline 2 and an airflow speed increaser 5, and the airflow speed increaser can ensure a constant flow rate of the flue gas entering the feed box.

[0022] The sloping plate feeding box is provided with raw material feeding hopper 3, vibrating screen 7 and five sloping plates 8 from top to bottom. The shaft is also connected with five parallel inclined plates in the inclined plate type feeding box, and the raw material on the inclined plates 8 is kept at a constant speed through the high-frequency oscillation of the oscillation device 4 .

[0023] The five-fold slanted plate arrangement greatly prolongs the contac...

Embodiment 2

[0029] The device is the same as in Example 1, the raw meal for grinding is cement mixed raw meal, the aperture diameter of the vibrating screen is selected as 0.25 cm, the folding plate material is stainless steel with good heat transfer performance, and the processing flow is the same as in Example 1.

[0030] The water content of cement mixed raw meal is low after pressure filtration, so the 0.25cm vibrating sieve is used to split the press-filtered cement mixed raw meal. Difference. The moisture content of the pre-dried calcium carbide slag is reduced from about 25% to meet the requirements of vertical grinding (about 18%); the dust removal rate of flue gas reaches more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com