Circular arc flat-bottom cupped light emitting diode manufacturing method

A production method and technology of concave cups, which are applied to electrical components, electric solid devices, circuits, etc., can solve the problems of difficult heat dissipation and uneven light source, and achieve the effects of low heat generation, uniform brightness, and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

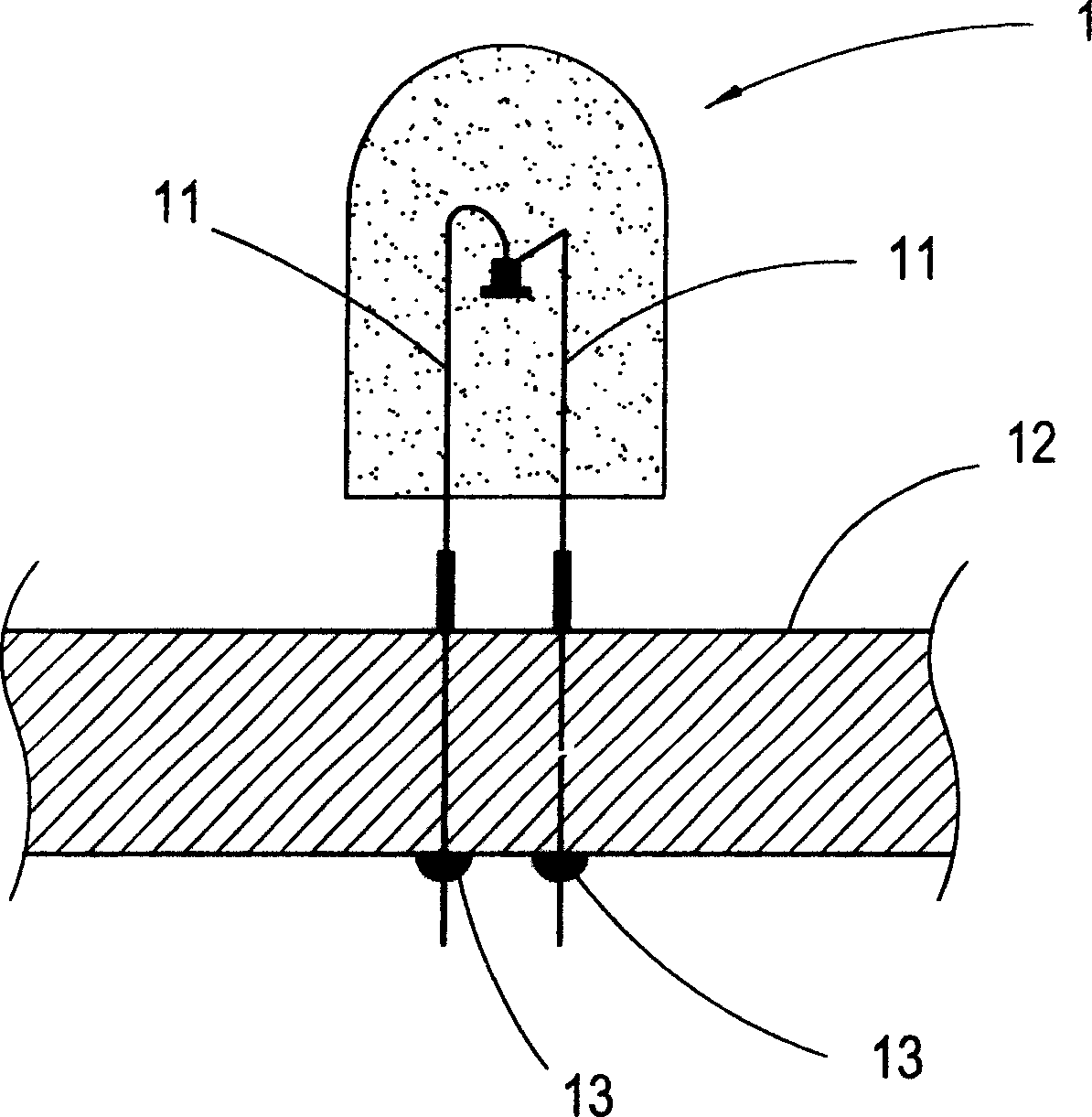

[0072] Such as figure 2 As shown, the concave cup type LED 2 of the present invention uses a CNC computer drilling machine on the printed circuit board, and utilizes a milling cutter to drill an arc flat-bottomed concave cup 211 with an R angle at 12,000 to 25,000 revolutions, and the chip 22 is arranged on the circle. In the curved flat-bottom concave cup 211 , the chip 22 is connected to the copper foil on the printed circuit board 21 by wire bonding technology, and finally encapsulated on it with epoxy resin glue 23 . The concave cup of the present invention directly uses the printed circuit board to dissipate heat, and the contact thermal resistance is extremely low, so it has the advantages of long-term resistance to instantaneous high current, low heat generation, uniform brightness, high stability, reduced cost, and greatly increased production capacity.

[0073] The general LED operating temperature calculation method is as follows:

[0074] 1. With an electronic squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com