Homogeneous composite cellulose/titanium oxide powder microspheres and its preparing process

A technology of composite microspheres and titanium dioxide, which is applied in the field of homogeneous cellulose/titanium dioxide composite microspheres and its preparation, can solve the problems of not developing a spherical expanded bed adsorption matrix, and achieve regular shape, easy control and scale-up , the effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The steps of the preparation method of homogeneous cellulose / titanium dioxide composite microspheres are as follows:

[0022] 1) Prepare composite water phase

[0023] At room temperature, mix titanium dioxide superfine particles and industrial cellulose xanthate viscose at 5%-40% by mass, stir evenly, heat up to 25-35°C, and continue stirring for 30-45 minutes.

[0024] 2) Suspension heating and solidification into balls

[0025] Stop stirring, add oil dispersion phase and surfactant, then start stirring, suspend and disperse at 25-35°C for 30-60 minutes, raise the temperature to 90-95°C, keep warm for 1.5-2 hours, the viscose solidifies to obtain microspheres.

[0026] 3) Regeneration of homogeneous microspheres

[0027] The solidified microspheres are filtered out from the oil phase, washed with 1 to 2 times the volume of benzene to remove the oil layer, and then regenerated with 2 to 3 times the volume of methanol, ethanol solution containing 30% acetic acid or 10...

Embodiment 1

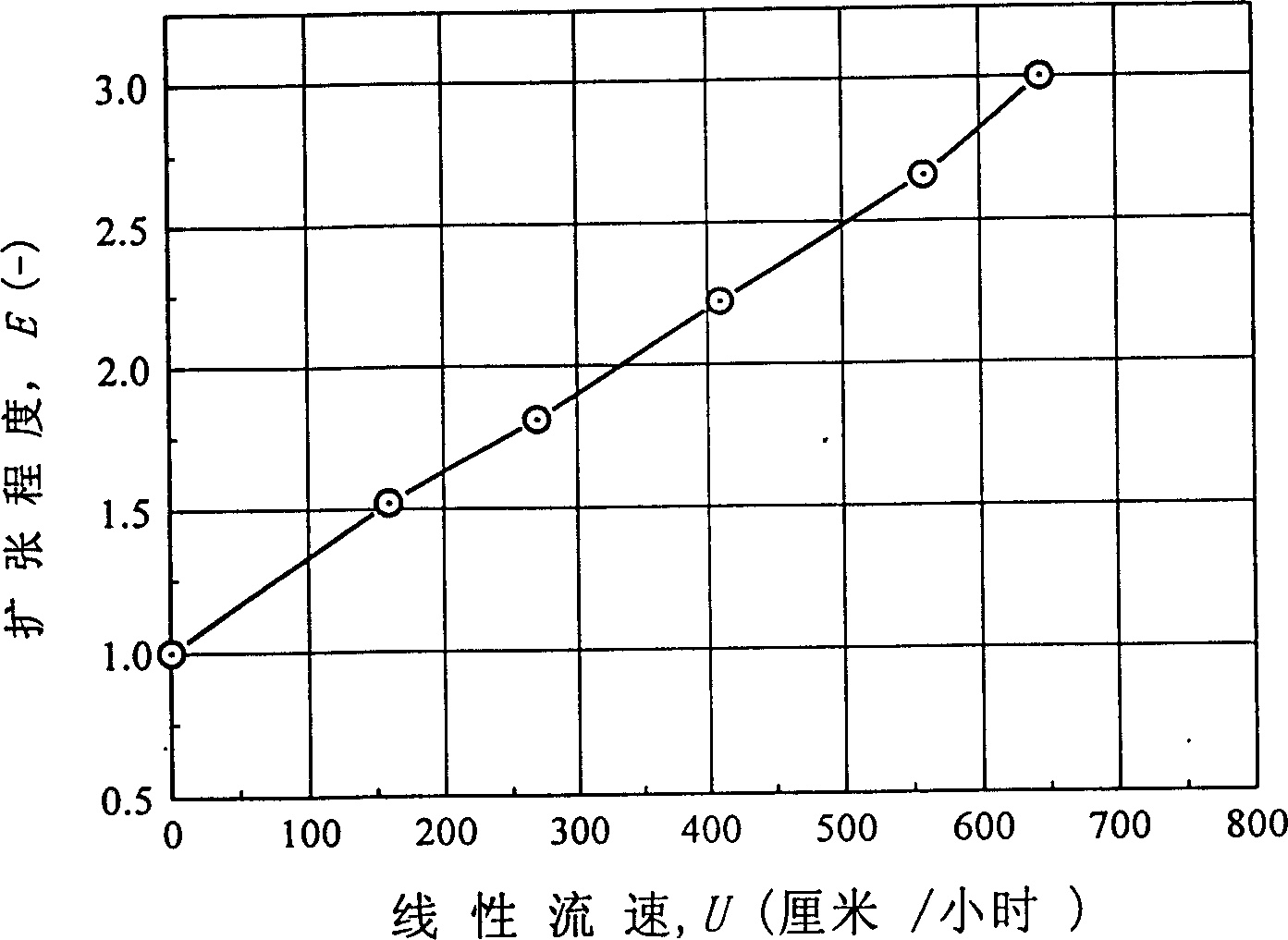

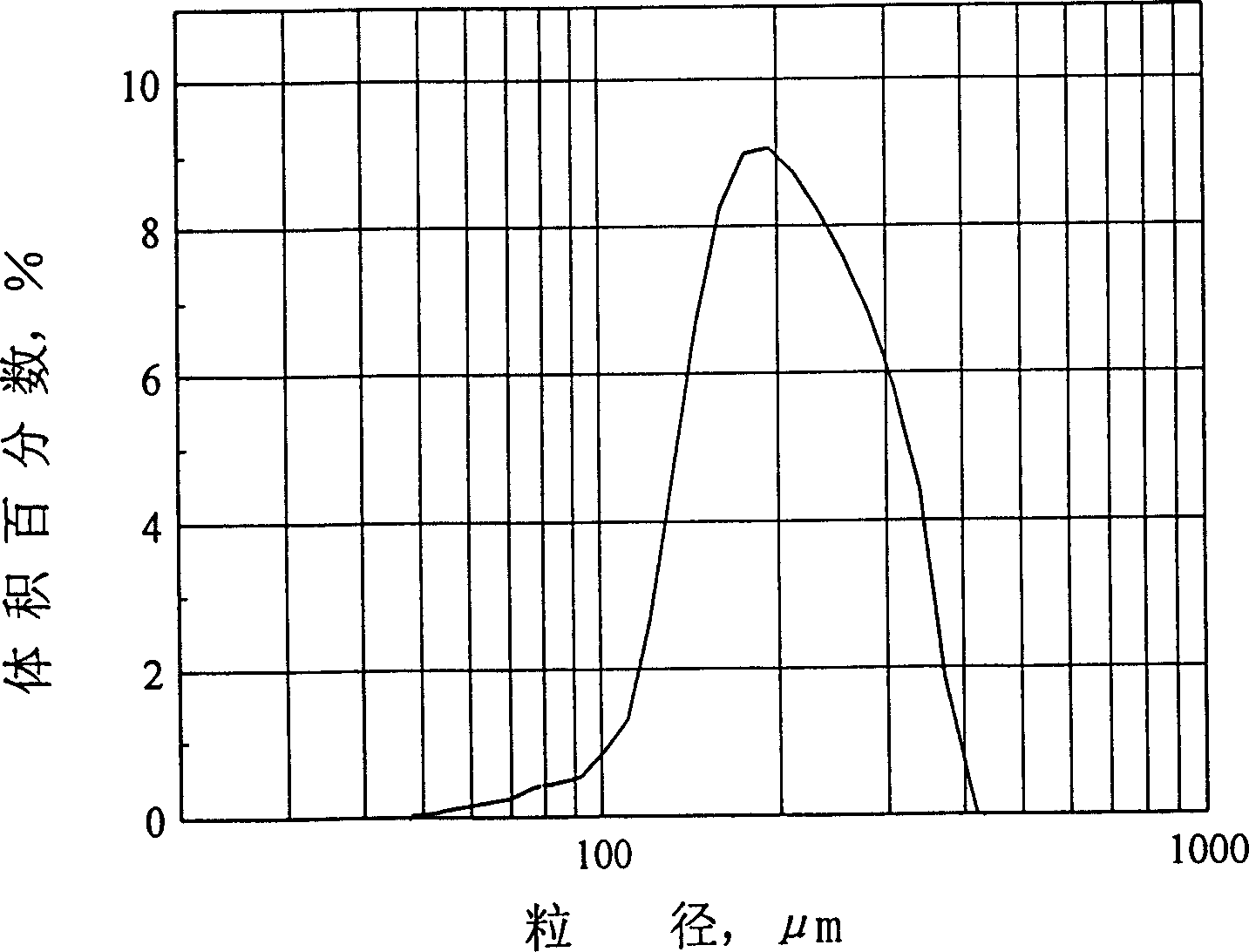

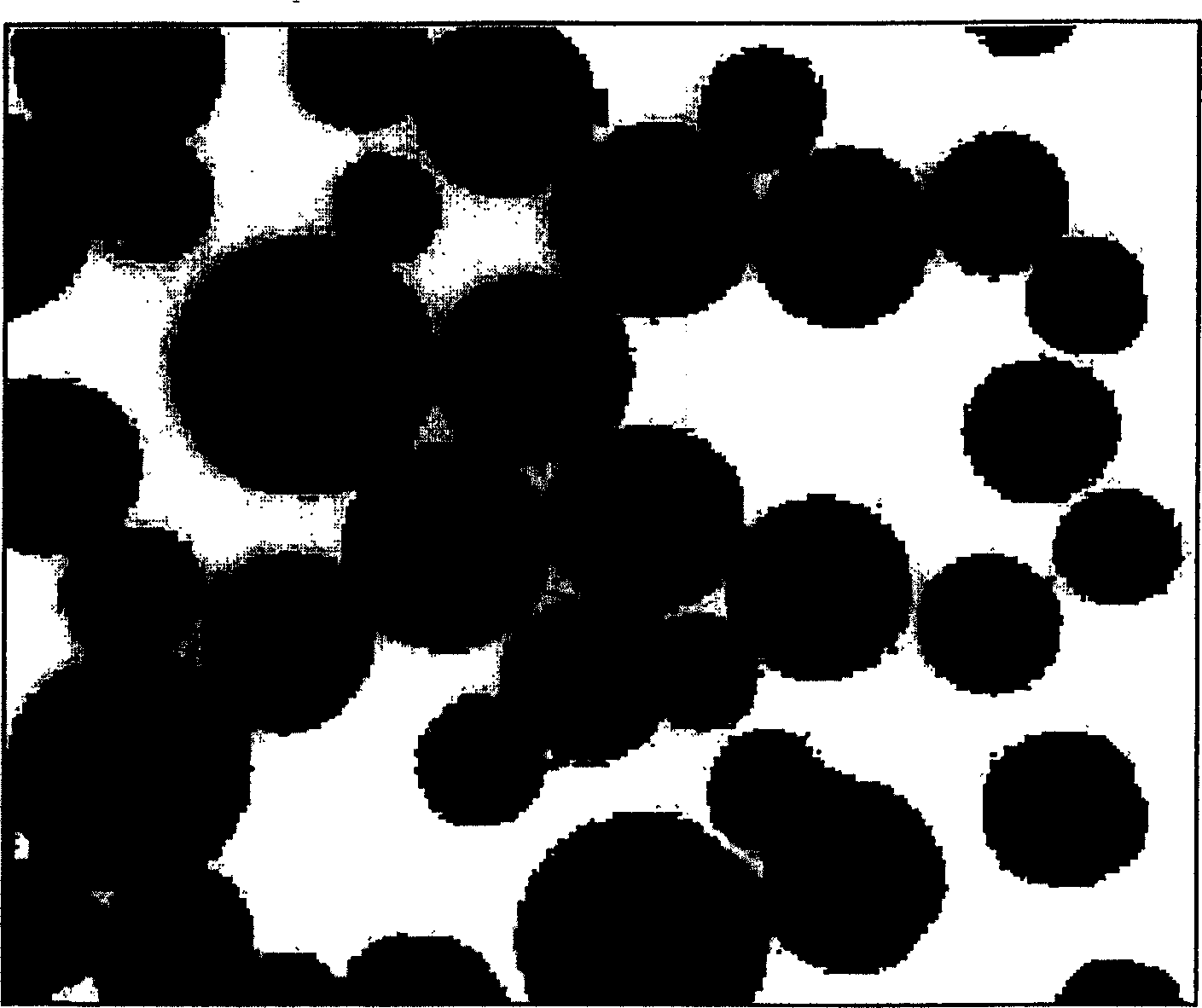

[0037] Add 100g industrial viscose (containing cellulose 8.2g, CS 2 3g, NaOH 6.2g, viscosity is 6800cSt) and 10g rutile type titanium dioxide, be warming up to 30 ℃ and stir for half an hour; Stop stirring, add 600mL by the mixed oil phase of pump oil and chlorobenzene preparation (pump oil: chlorobenzene=4: 1, mass ratio), adjust the stirring speed to 450rpm, keep the speed constant, suspend and disperse at 30°C for 45 minutes, raise the temperature to 90°C within 15 minutes, keep warm for 1.5 hours, and solidify to obtain yellow-white microspheres; microspheres from the oil phase filtered out, washed with 150mL benzene for 1 hour, regenerated with 200mL methanol for 1 hour, and regenerated with 200mL ethanol solution containing 30% acetic acid for 1 hour, washed with tap water three times, and sieved in a wet state to obtain particles with a particle size between 100 and 300 μm. White ball 42mL, density 1.16g / cm 3 .

Embodiment 2

[0039] Add 100g of the above-mentioned industrial viscose and 10g of anatase titanium dioxide in a 1-liter three-necked flask, heat up to 30°C and stir for half an hour; add 450mL of mixed oil phase prepared by pump oil and chlorobenzene (pump oil: chlorobenzene=6: 1, mass ratio) and 0.9g oleic acid, adjust the stirring speed to 300rpm, suspend and disperse at 30°C for 1 hour, heat up to 90°C within 15 minutes, keep warm for 1.5 hours, and solidify to obtain yellow-white microspheres; microspheres from the oil phase filtered out, washed with 200mL of benzene for 1 hour, 200mL of methanol for 1 hour, 200mL of 10% sulfuric acid solution for 1 hour, washed with tap water three times, and sieved in a wet state to obtain 48mL of white balls with a particle size between 100 and 300μm. The density is 1.16g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com